Preparation method of 4-bromo phthalic anhydride

A technology of bromophthalic anhydride and phthalic anhydride, applied in the field of preparation of 4-bromophthalic anhydride, can solve the problems of difficulty in improving product yield and purity, complicated operation and high cost, and achieve high product yield, high purity, and production energy consumption reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

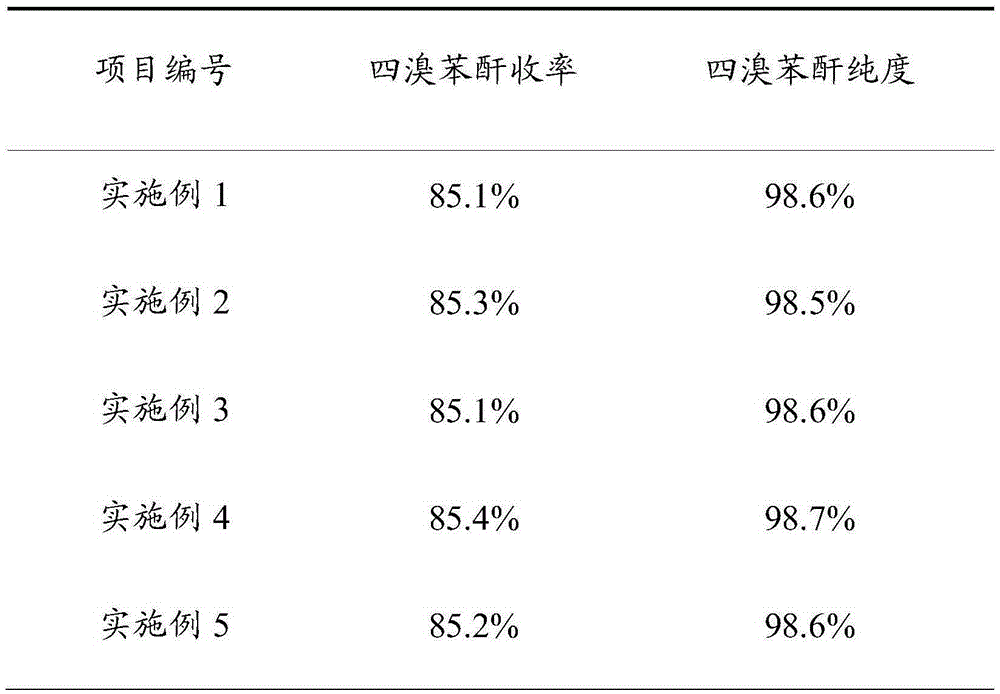

Examples

Embodiment 1

[0022] Embodiment 1, this embodiment provides a kind of preparation method of 4-bromophthalic anhydride. First, dissolve 5.6g of sodium hydroxide in 22.4g of water, add 10g of phthalic anhydride and stir thoroughly, then add 0.1g of tetrabutylammonium bromide catalyst and continue to stir evenly. Then use three-stage program temperature control and add reactants three times to react. The temperature control temperature of the first stage is 40°C, the mass of bromine added is 5g, and the reaction time is 1.5 hours; the temperature control temperature of the second stage is 60°C. , the mass of bromine added is 5g times, and the reaction time is 4.5 hours; the third stage temperature control temperature is 75°C, the mass of additional sodium hydroxide is 1g, the mass of bromine added is 4g, and the reaction time is 4.5 hours; the reaction ends Finally, 5 g of 20% oleum solution was added to the reaction solution, and the temperature was raised to 90° C. for acidification. After a...

Embodiment 2

[0023] Example 2, this example provides a preparation method of 4-bromophthalic anhydride, first dissolve 5g of sodium hydroxide in 30g of water, add 10g of phthalic anhydride and stir thoroughly, then add 0.5g of tetraethylammonium bromide catalyst and continue stirring uniform. Then use three-stage program temperature control and add reactants three times to react. The temperature control temperature of the first stage is 50°C, the mass of bromine added is 6g, and the reaction time is 2.5 hours; the temperature control temperature of the second stage is 70°C. , the mass of bromine added is 6g, and the reaction time is 6 hours; the third stage temperature control temperature is 85°C, after adding 2g of sodium hydroxide, bromine is added to continue the reaction, the mass of bromine added is 6g, and the reaction time is 5.5 hours Add 20% oleum 8g to the reaction product after the three-stage temperature control program reaction finishes, heat up to 100°C for acidification, coo...

Embodiment 3

[0024] Embodiment 3, this embodiment provides a kind of preparation method of 4-bromophthalic anhydride. First, dissolve 5.3g of solid sodium hydroxide in 26.5g of deionized water, add 10g of phthalic anhydride and stir thoroughly, then add 0.3g of benzyltriethylammonium chloride catalyst and continue to stir evenly. Then adopt the method of three-stage temperature control and add the reactant three times to carry out the reaction. The first stage temperature control temperature is 48 ℃, the quality of bromine added is 5.6g of the mass of phthalic anhydride, and the reaction time is 2 hours; The temperature is 64°C, the mass of bromine added is 5.4g, and the reaction time is 5.1 hours; the third stage temperature control temperature is 82°C, after adding 1.4g of sodium hydroxide, bromine is added to continue the reaction, and the mass of bromine added is 5g, the third reaction time is 5 hours; after the reaction, add 6g of 20% oleum to the product, and heat up to 95°C for acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com