Technology for recycling low-calcium and low-chlorine purified water

A water purification and process technology, applied in the field of environmental engineering, can solve the problems of high cost, achieve the effect of high reuse rate of reused water, realize zero discharge of waste water, and low cost of waste water treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

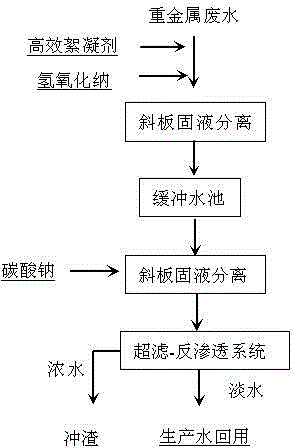

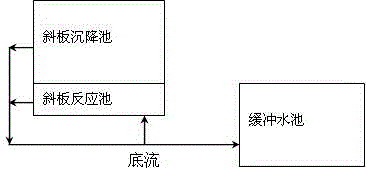

[0018] Such as figure 1 As shown, one or several high-efficiency flocculants of polyiron, polyaluminum, and polyacrylamide are added to heavy metal-containing wastewater, and the groups in the flocculant and heavy metal ions undergo a coordination reaction to form alum flowers. Liquid caustic soda, adjust the pH to 9-11 to make the coordination bond more stable and facilitate the settlement. Finally, the solid-liquid separation is carried out through the inclined plate settling tank to remove most of the heavy metal ions.

[0019] The supernatant water after removing heavy metal ions enters the buffer pool, and the water in the buffer pool is added with sodium carbonate, Na 2 CO 3 .10H 2 O is 99% industrially pure, with a concentration of 10% and a density of about 1.2 g / mL. It is necessary to reduce the calcium ion content of the pretreated water to less than 50 mg / L, and add an excess of 1.5 times according to the excess coefficient. For wastewater with a calcium content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com