A treatment method for denitrification and fluorine removal and reuse of silicon industry wastewater

A technology for industrial wastewater and treatment methods, applied in the field of wastewater treatment, can solve the problems of large wastewater treatment volume and large amount of acid and alkali, and achieve the effects of low operating cost, reduced floor space, and high water reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

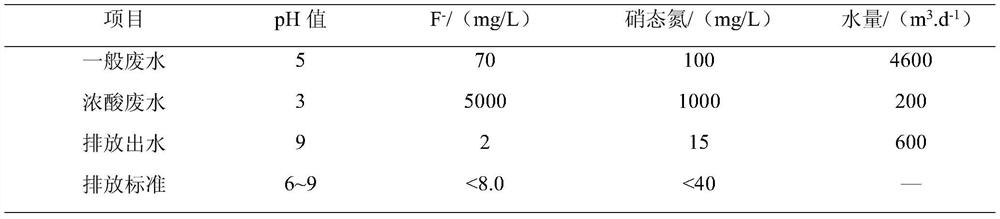

Embodiment 1

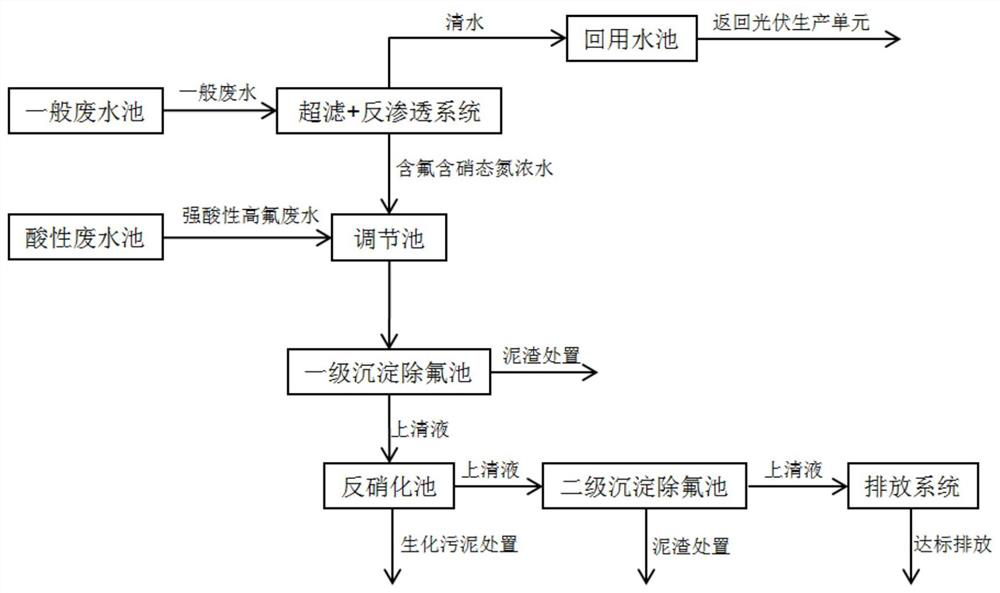

[0037] A treatment system for implementing the treatment method of denitrification, fluorine removal and reuse of wastewater from silicon industries such as photovoltaics and integrated circuits, including a general wastewater tank, an ultrafiltration membrane, a reverse osmosis membrane, a reused water tank, an acidic wastewater tank, Regulating tank, primary sedimentation defluorination tank, denitrification tank, secondary sedimentation defluorination tank and discharge system, general wastewater tank, regulating tank, primary precipitation defluorination tank, denitrification tank, secondary precipitation defluorination tank and discharge The systems are connected sequentially, the acidic wastewater pool is connected to the regulating pool, the clear water effluent from the reverse osmosis system is introduced into the reuse pool and returned to the silicon industry production units such as photovoltaics and integrated circuits, and the wastewater flows in from the general w...

Embodiment 2

[0053] Such as figure 1 Shown, system and treatment method step are the same as embodiment 1, and difference is, in step (1), general waste water is separated into fluorine-containing nitrate nitrogen concentrated water of 5% volume and the clear water of 95% volume; The mixing ratio of the concentrated fluorine-containing nitrate nitrogen water and the strongly acidic high-fluorine wastewater from the acid wastewater pool is 1.2:1.5; the concentration of fluoride ions in the wastewater after the primary precipitation in step (3) is 880 mg / L, and the concentration of nitrate nitrogen 1500mg / L, the pH of the waste water supernatant is 6; the organic matter is methanol in the step (4), the pH value of the denitrification tank effluent is 8, and the total nitrogen concentration is 25mg / L; in the step (6), the secondary precipitation defluorination F in the wastewater supernatant discharged from the pool - The concentration is 4mg / L, the total nitrogen concentration is 25mg / L, an...

Embodiment 3

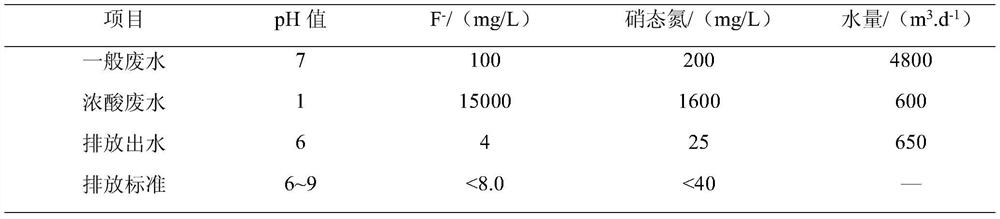

[0058] Such as figure 1 Shown, system and treatment method step are the same as embodiment 1, and difference is, in step (1), general waste water is separated into the fluorine-containing nitrate nitrogen concentrated water of 3% volume and the clear water of 97% volume; The mixing ratio of the fluorine-containing nitrate-nitrogen concentrated water and the strongly acidic high-fluorine wastewater from the acidic wastewater pool is 1:2, wherein the volume of the fluorine-containing nitrate-nitrogen concentrated water and the concentrated acid wastewater are 300m 3 / d and 600m 3 / d; In the step (3), the fluoride ion concentration in the waste water after the first-level precipitation is 950mg / L, and the nitrate nitrogen concentration is 1600mg / L, and the pH of the waste water supernatant is 5.5; Organic matter is acetic acid in the step (4). The pH value of the nitrification pond effluent is 9, and the total nitrogen concentration is 25mg / L; - The concentration is 5mg / L, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com