Treatment method for destabilization three-phase separation of emulsified oil-in-water oily wastewater

An oil-in-water type and three-phase separation technology, which is applied in the direction of oxidation water/sewage treatment, water/sewage treatment, mining wastewater treatment, etc., can solve the problem that electrocoagulation treatment is not simple enough, cannot form a closed-loop process, is not environmentally friendly, etc. problem, to achieve the effect of ingenious selection of components, appropriate design and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

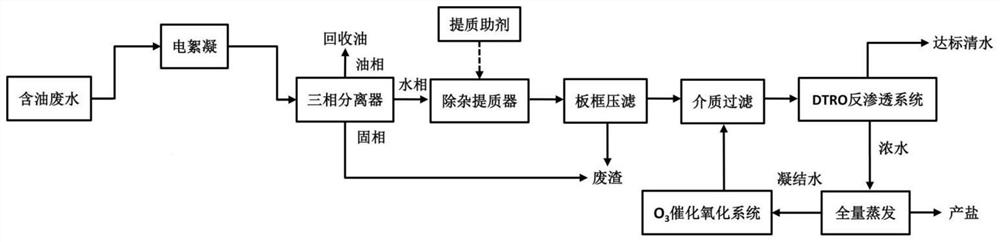

[0036] Oily wastewater can be divided into emulsified oil-in-water type and water-in-oil type according to water quality conditions, and the present invention provides a destabilized three-phase separation treatment method for oily wastewater, which is aimed at emulsified oil-in-water type oily wastewater Phase recycling, such as figure 1 Shown, main technological process of the present invention is as follows:

[0037] (1) Electrocoagulation process is used to destabilize the emulsified oil-in-water type oily wastewater;

[0038] In the electroflocculation process, the material of the electrolysis plate is high-purity aluminum, and the thickness of the plate is 3-5mm, the distance between the positive and negative plates is 8-10mm, the electrolysis current is 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com