Copper strike plating bath

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

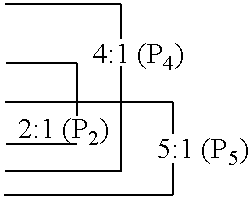

Image

Examples

Example

Comparative Example 1

[0025]Potassium copper cyanide185g / LPotassium cyanide10 to 80g / L

[0026] When current efficiency was measured during copper strike plating under conditions of 50° C. and 8 A / dm2 onto an iron-nickel alloy material in a copper strike plating bath having the above composition (the cyanide concentration changes according to the amount of potassium cyanide), it fluctuated from 10 to 90% depending on the cyanide concentration. In addition, the pH of the bath fluctuated from 9 to 12 depending on the cyanide concentration.

Example

Comparative Example 2

[0027]Potassium copper cyanide80 g / LPotassium cyanide30 g / L

[0028] When current efficiency was measured during copper strike plating within a current density range of 3 to 12 A / dm2 at 50° C. onto a copper alloy material in a copper strike plating bath having the above composition, current efficiency was 10% or less.

Example

Comparative Example 3

[0029]Potassium copper cyanide190 g / LPotassium cyanide 30 g / L

[0030] When current efficiency was measured during copper strike plating under conditions of 50° C. and 8 A / dm2 onto a copper alloy material in a copper strike plating bath having the above composition, current efficiency was 50%.

[0031] Moreover, when copper plating was carried out at a thickness of 0.2 μm onto an iron-nickel alloy material using this bath, the resulting plating demonstrated a uniform, semi-bright appearance. When this test piece was heated on a hot plate at 400° C., adhesion was satisfactory and heating blisters were not formed. In addition, when the same heating test was carried out on a test piece subjected to copper strike plating at a thickness of 0.1 μm followed by silver plating at a thickness of 5 μm, there was no occurrence of discoloration, blistering or peeling of the silver plating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com