Alkaline high-calcium wastewater decalcification treatment method

A treatment method and waste water technology, applied in water/sewage multi-stage treatment, neutralized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of limited application range and high treatment cost, and reduce salt content , waste water treatment cost reduction, water quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

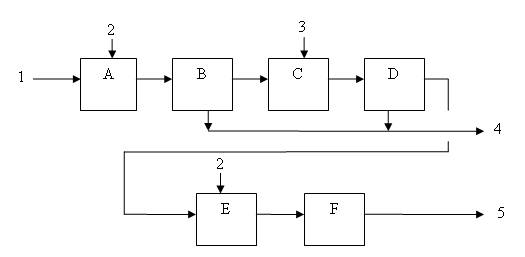

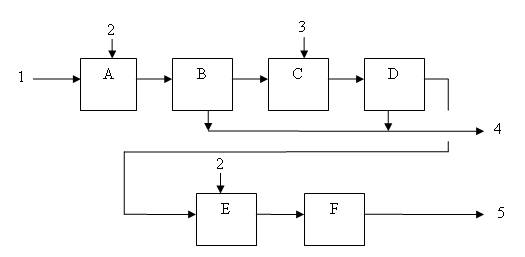

[0021] The technological process of the inventive method is referred to accompanying drawing. Alkaline high-calcium wastewater 1 (pH 11.0-12.3, Ca concentration 679-1642 mg / L) generated from acid wastewater treatment enters the first neutralization tank A, and is treated with carbon dioxide waste gas 2 (CO 2 Concentration of 30% to 90%) aeration for pre-neutralization treatment, the pH is controlled at 9.0 to 10.0, and the aeration time is 5 to 40 minutes, so that the Ca(OH) in the wastewater 2 CaCO 3 Precipitate and drive the supersaturated CaSO in the wastewater 4 Co-precipitation; the pre-neutralized suspended wastewater enters the first sedimentation tank B, and the sedimentation time is 30 to 90 minutes; the supernatant wastewater of the first sedimentation tank B enters the reaction tank C, and sodium carbonate 3 is added under mechanical stirring. The addition of sodium carbonate 3 is controlled so that the mol ratio of sodium carbonate 3 and calcium in the waste wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com