Method for treating sewage utilizing oil refining waste catalyst

A technology for refining waste catalyst and treatment method, applied in the direction of adsorbed water/sewage treatment, etc., can solve the problems of oily sewage without better adsorption function, harsh regeneration conditions of adsorbent, and difficulty in multiple utilization of adsorbent, and achieve a good social economy. Benefit, ease of use, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

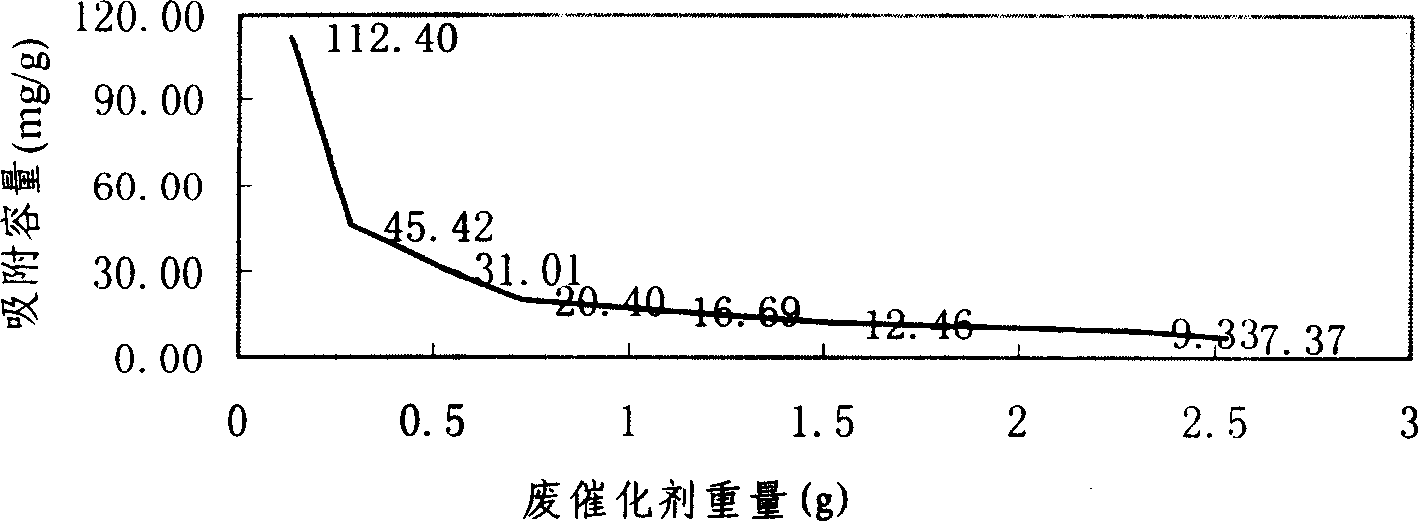

[0025] This example is an experiment of the adsorption effect of waste catalyst on oil refinery wastewater. Sewage COD is 154mg / L, spent catalyst composition is Al 2 o 3 The content is 52.1 wt%, SiO 2 The content is 42.4% by weight, P 2 o 5 The content is 0.38% by weight, other components such as Na 2 O, MgO, K 2 O, CaO, TiO 2 、Re 2 o 3 The equivalent content is 5.12% by weight.

[0026] Take 150mL of refining water, put it into a 250mL beaker, and start stirring at a speed of 150r / min. Sampling and measuring COD at regular intervals to obtain the instantaneous adsorption amount, and obtain the limit adsorption amount by drawing a curve. see results figure 1 . It can be seen from the results in the figure that the spent catalyst has a higher limit adsorption capacity for refinery water, and has a unique adsorption property for organic matter in refinery water.

Embodiment 2

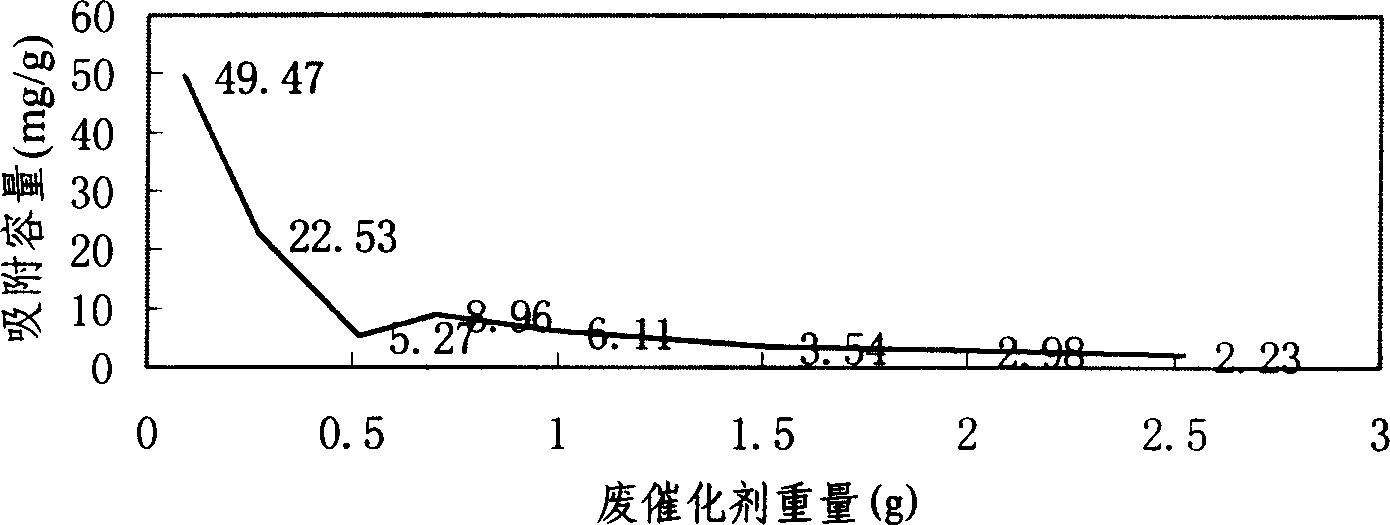

[0028] This example is an experiment on the adsorption effect of waste catalysts on chemical wastewater. The sewage COD is 175.8mg / L, and the spent catalyst composition is Al 2 o 3 The content is 52.1 wt%, SiO 2 The content is 42.4% by weight, P 2 o 5 The content is 0.38% by weight, other components such as Na 2 O, MgO, K 2 O, CaO, TiO 2 、Re 2 o 3 The equivalent content is 5.12% by weight.

[0029] Get chemical water 150mL, carry out experiment according to embodiment 1 method, the result sees figure 2 . figure 2 It shows that the value of the limit adsorption capacity of spent catalyst to refinery water is moderate, and the spent catalyst has certain selectivity for the adsorption of different organic substances.

Embodiment 3

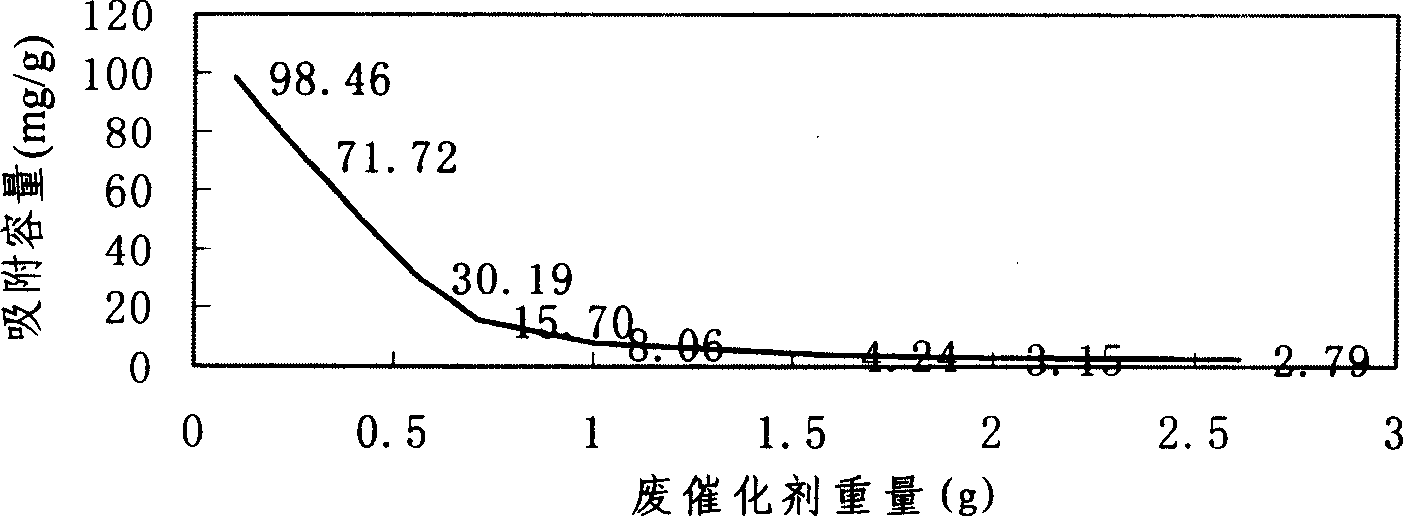

[0031] This example is an experiment on the adsorption effect of waste catalyst on urban sewage. The sewage COD is 212.6mg / L, and the spent catalyst composition is Al 2 o 3 The content is 52.1 wt%, SiO 2 The content is 42.4% by weight, P 2 o 5 The content is 0.38% by weight, other components such as Na2 O, MgO, K 2 O, CaO, TiO 2 、Re 2 o 3 The equivalent content is 5.12% by weight.

[0032] Get urban sewage 150mL, carry out experiment according to embodiment 1 method, the result sees image 3 . image 3 It shows that although the COD of urban sewage is higher, compared with industrial sewage, the organic matter in sewage is easier to be adsorbed, so the value of the limit adsorption capacity of spent catalyst is higher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com