Preparation method and application of a kind of citric acid modified rape straw adsorbent

A technology of rape straw and citric acid, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, to achieve the effects of wide sources, good treatment effect and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of citric acid modified rape straw adsorbent, the specific steps are as follows:

[0026] (1) Physical treatment of materials

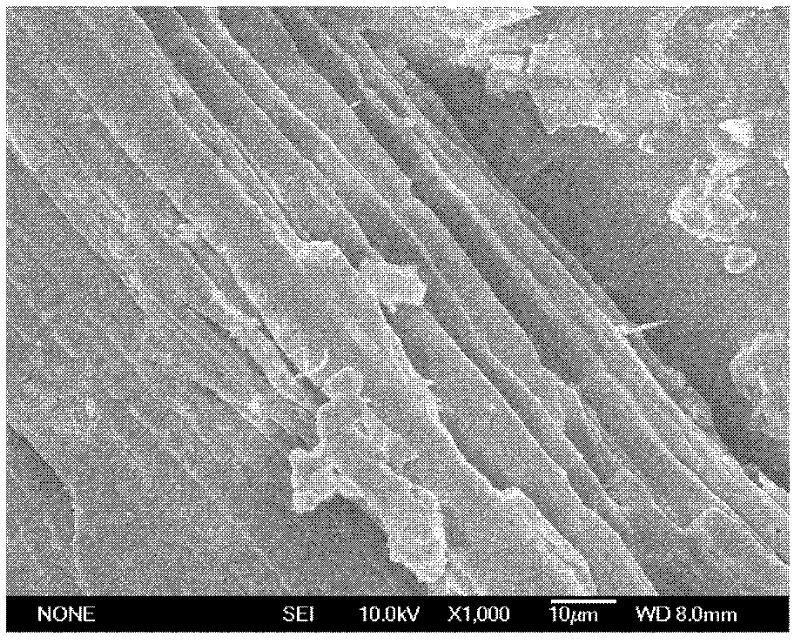

[0027] Cut the dried rape stalks into small pieces and grind them further with a mixer, then pass through a 100-mesh sampling sieve, wash the lower part of the sampling sieve with distilled water for 4 times, and filter with a vacuum pump until the filtrate becomes clear. Dry the powder in an electric blast drying oven at 55°C for 24 hours to obtain dried rape straw powder. figure 1 It is a scanning electron microscope picture of dried rape straw powder. It can be seen from the figure that rape straw has a fibrous structure.

[0028] (2) Chemical modification

[0029] ① Just immerse the dried rape straw powder in 20v / v% isopropanol, stir it for 24 hours, filter it with a vacuum pump, wash it with 20v / v% isopropanol for 3 times, and finally wash it with distilled water until the filtrate becomes clear. The solid was dried...

Embodiment 2

[0036] Put 50mg of adsorbent into a 250mL Erlenmeyer flask with a stopper, add 50mL to a concentration of 200mg L -1 Crystal violet dye aqueous solution, the pH value of the dye solution is 5.0, and shake at a speed of 150rpm in a water bath shaker at 25°C for 0.5h, then take out the Erlenmeyer flask, pour out the solution and separate the solution from the solid at a speed of 10000rpm on a centrifuge, The obtained supernatant was measured with a spectrophotometer at the maximum absorption wavelength (588nm) of crystal violet for its absorbance, and the concentration of the remaining dye was detected, thereby obtaining a removal rate of 97.43% for the dye crystal violet.

Embodiment 3

[0038] Put 50mg of adsorbent into a 250mL Erlenmeyer flask with a stopper, add 50mL to a concentration of 300mg L -1 An aqueous solution of crystal violet dye, the pH of the dye solution is 5.32, shake in a water bath shaker at 25°C at a speed of 150rpm for 0.5h, then take out the Erlenmeyer flask, pour out the solution and separate the solution from the solid at a speed of 10000rpm on a centrifuge, The obtained supernatant was measured with a spectrophotometer at the maximum absorption wavelength (588nm) of crystal violet for its absorbance, and the concentration of the remaining dye was detected, thereby obtaining a removal rate of 99.09% for the dye crystal violet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com