Method for treating coking waste water by electro-Fenton-coagulation combination process

A coking wastewater and combined process technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as difficulty in COD compliance, achieve low operating costs, and significant treatment effects , Facilitate the effect of engineering popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

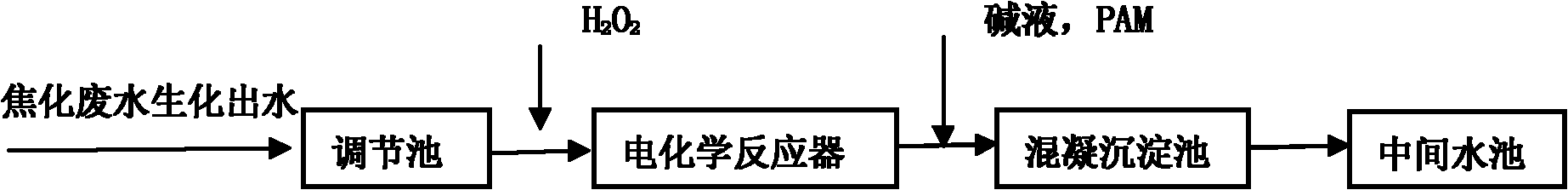

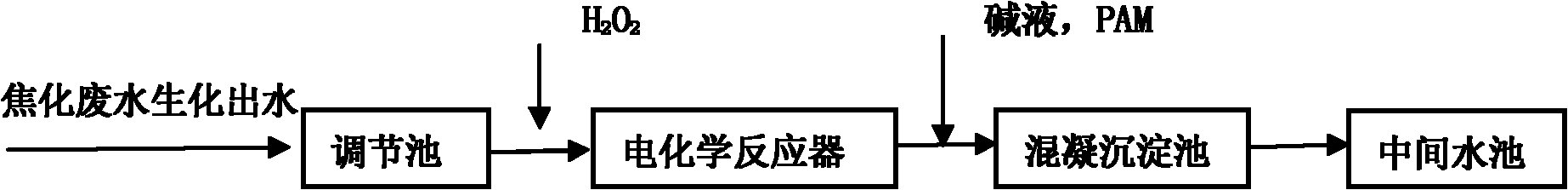

Method used

Image

Examples

Embodiment 1

[0036] The COD of the effluent from the secondary sedimentation tank of a coking plant wastewater plant in Shanxi is 120-150mg / L, and other indicators have reached the national first-level discharge requirements.

Embodiment 2

[0039] The biochemical effluent COD of a coking plant wastewater plant in Inner Mongolia is 106mg / L, and other indicators have met the national first-level discharge requirements.

[0040] Advanced treatment is carried out using the electro-Fenton-coagulation method described in the present invention. The biochemical effluent of coking wastewater enters the regulating tank, and acid solution is added to adjust the pH to 2.6, and then enters the electrochemical reactor, and the H 2 o 2 The dosage is 150mg / L, and the current density is adjusted to 200A / m 2 , the residence time is 20min, the electrochemical reactor effluent enters the coagulation sedimentation tank, the pH is adjusted to 7-8 by adding lye, the flocculant PAM dosage is 0.5mg / L, the residence time is 15min, and the COD of the effluent is 42mg / L L, discharge up to the standard or enter the intermediate pool for reuse treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com