Fluorine-containing wastewater treatment method

A waste water treatment, waste water technology, applied in water/sewage multi-stage treatment, neutralized water/sewage treatment, water/sludge/sewage treatment, etc., can solve waste of calcium chloride consumption, short treatment time, pH monitoring Inaccurate and other problems, to achieve the effect of saving chemical consumption, sufficient chemical reaction time, and reducing environmental impact factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to better understand the technical content of the present invention, specific embodiments are given and described as follows in conjunction with the accompanying drawings.

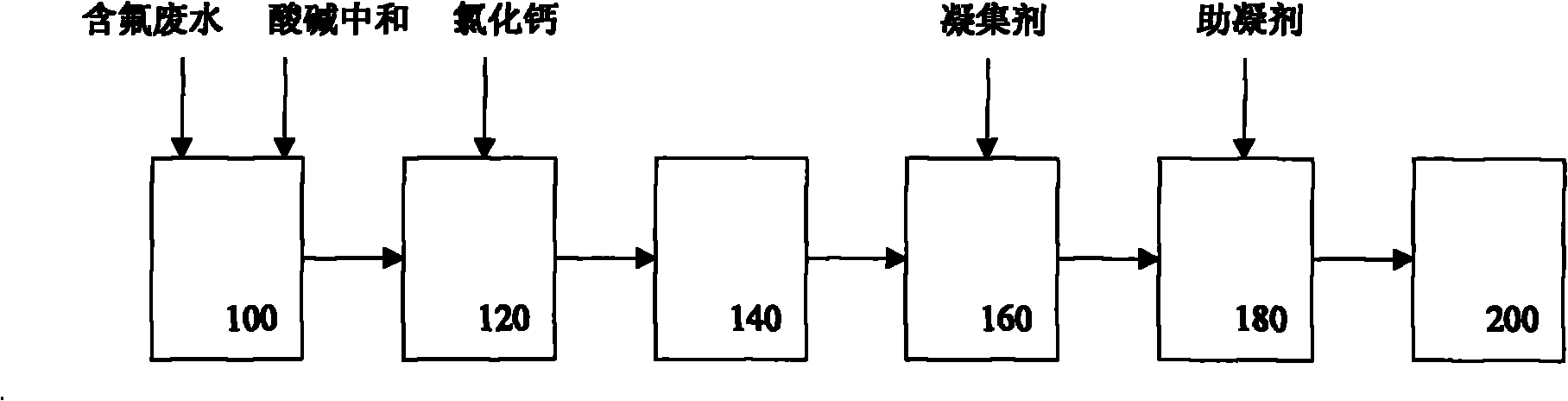

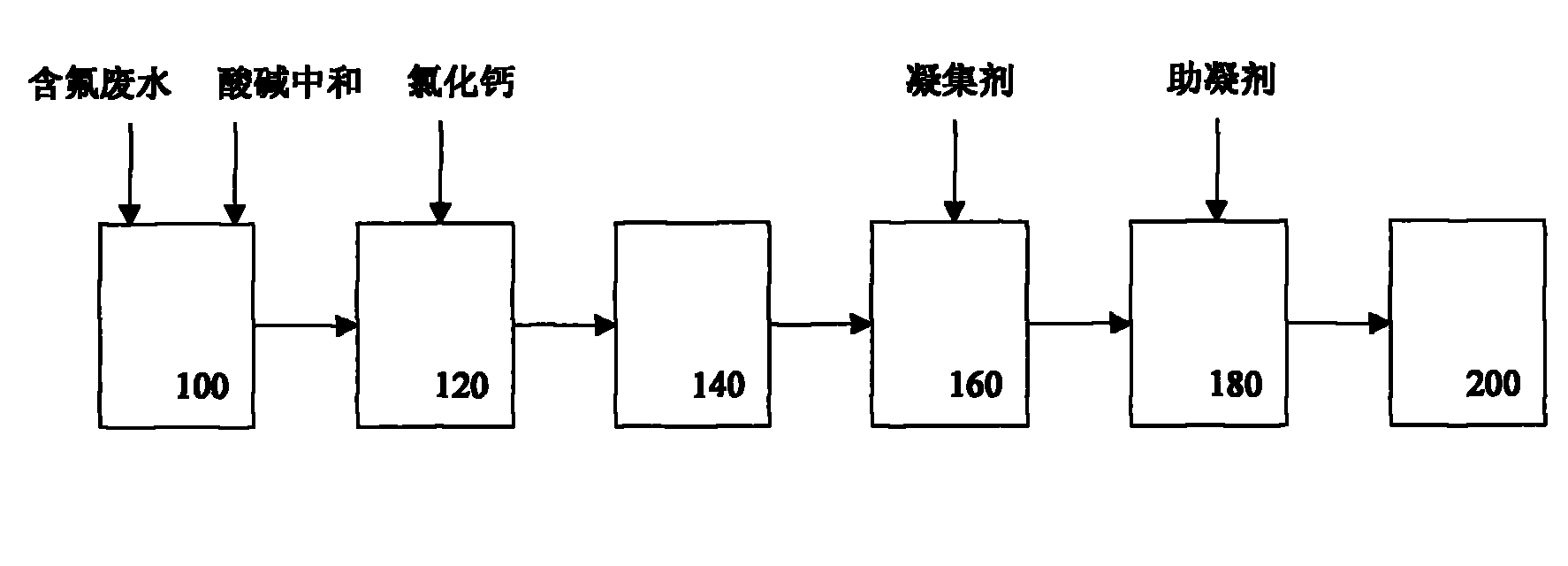

[0037] Please refer to figure 2 , figure 2 Shown is a schematic diagram of a fluorine-containing wastewater treatment system in a preferred embodiment of the present invention. Such as figure 2 As shown, after the factory produces fluorine-containing waste water, these fluorine-containing waste water are first stored in the source water tank 100 for temporary storage. The volume of the source water tank 100 is about 50 cubic meters. The liquid level starts to rise slowly. During the rising process of the liquid level of the source water tank 100, two circulation pumps can be used to play the role of hydraulic stirring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com