Mechanical deep dehydration, biological desiccation and reclamation combined treatment process for sewage sludge

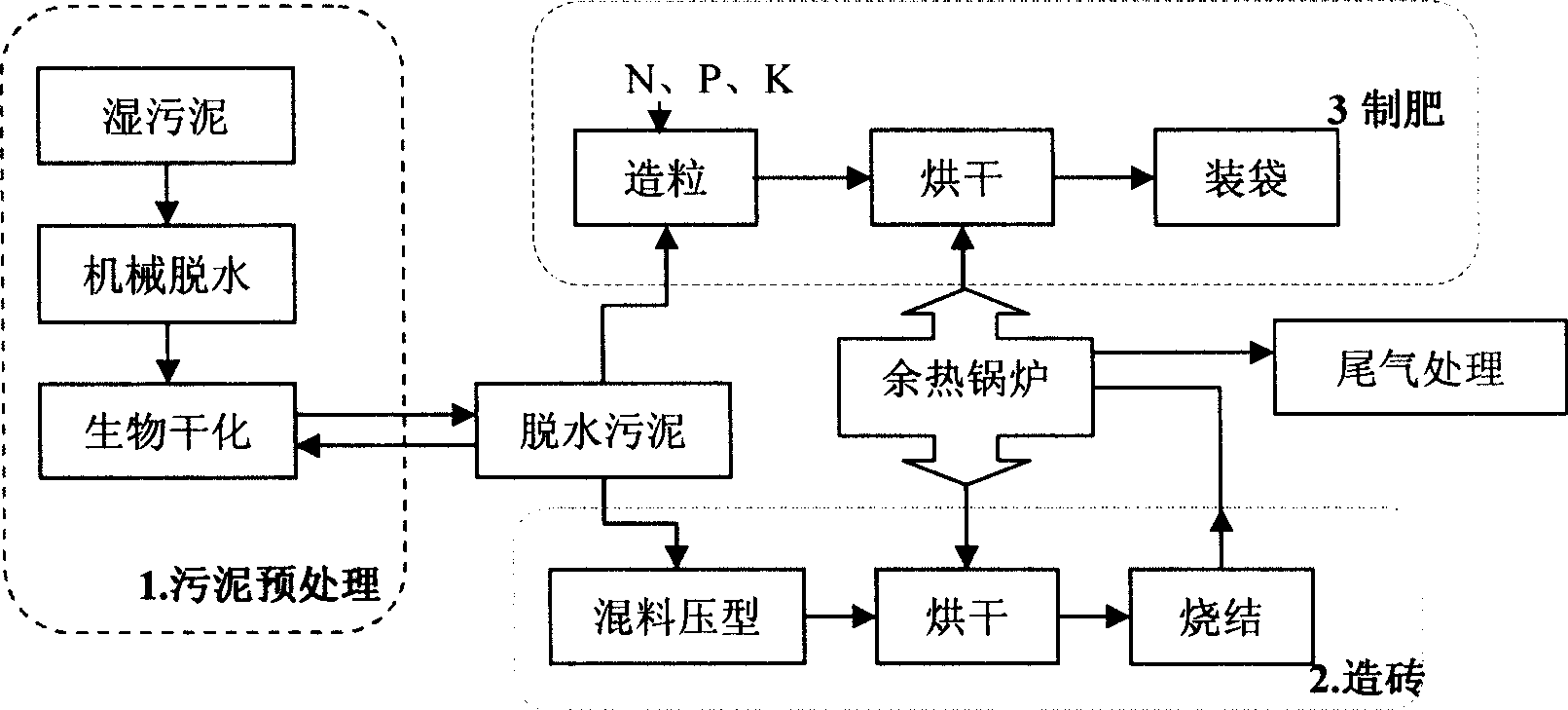

A technology of biological drying and deep dehydration, which is applied in sludge treatment, biological sludge treatment, dewatering/drying/concentrating sludge treatment, etc. It can achieve the effect of reducing storage area, obvious sludge reduction and less chemical consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] 1. Mechanical dehydration

[0029] The sludge with a moisture content of more than 99% in the sewage plant is concentrated by gravity, and then transported to the mechanical dehydration system, and the moisture content of the sludge is reduced to 60-65% by mechanical dehydration through a diaphragm high-pressure plate and frame filter press;

[0030] 2. Biological drying

[0031] The mechanically dehydrated sludge is transported to the biological drying workshop for further drying. In the biological drying workshop, after mechanical dehydration, the wet sludge with a moisture content of less than 65% and part of the dry sludge with a moisture content of 30% are mixed through a distribution machine , and then through the turning and throwing of the turning and throwing machine to realize the uniform mixing of the materials, the moisture content of the mixed materials is reduced to below 60%, and the forced ventilation is carried out during the biological drying process t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com