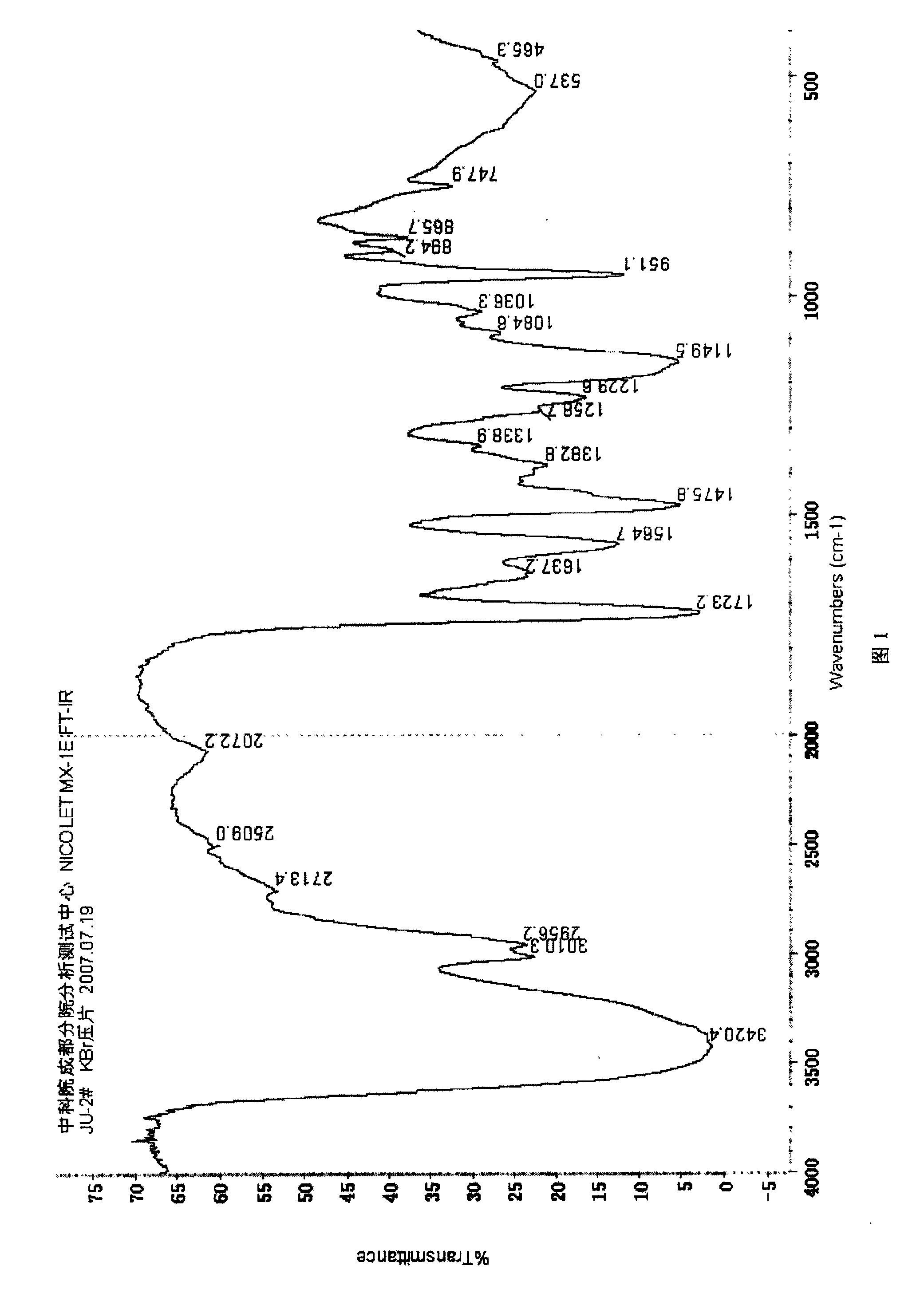

Organic high polymer coagulant and preparation method thereof

An organic polymer and flocculant technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of secondary pollution, low storage stability, not in line with green chemistry and environmental protection, etc. The effect of uniform charge distribution and improved wastewater treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

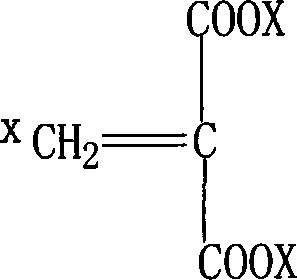

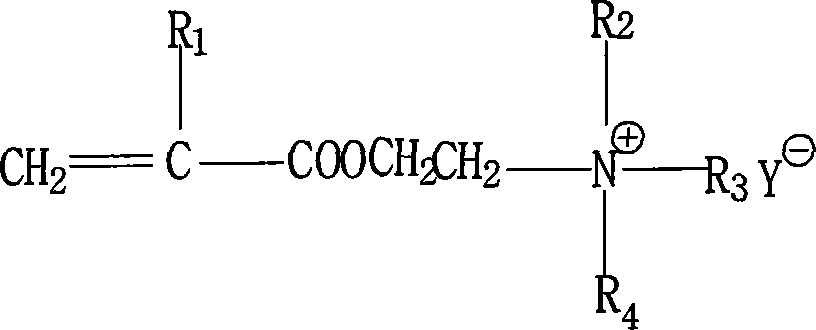

[0042] Step 1. In a 250mL four-neck reactor equipped with a thermometer, a nitrogen device and an agitator, add 51g of distilled water, 3g of itaconic acid (salt) and 1.8g of sodium hydroxide, then add 0.0086g of hexamethylenediaminetetraacetic acid Sodium, start stirring, then add 7g of tertiary ammonium (alkyl) acrylate dialkylaminoethyl ester, stir in vacuum, pass nitrogen, and heat up to 40°C;

[0043] Step 2, under the conditions of continuous stirring and nitrogen flow, start to slowly add 33g of quaternized alkyl acrylate dialkylaminoethyl, add redox initiator potassium persulfate and sulfite equivalent to 0.4% of the total mass of the monomer 0.0464g of the sodium bisulfate mixture initiates the copolymerization of the two monomers and keeps the temperature for 4h;

[0044] Step 3, heat up to 80°C, add 0.0215g of water-soluble azo initiator azobisisobutylamidine hydrochloride equivalent to 0.05% of the total mass of monomers, continue to react for 4h, cool to normal te...

Embodiment 2

[0046] Step 1. In a 250mL four-neck reactor equipped with a thermometer, a nitrogen device and an agitator, add 73g of distilled water, 5g of itaconic acid (salt) and 3.07g of sodium hydroxide, then add 0.0066g of hexamethylenediaminetetraacetic acid Sodium, start stirring, then add 9g of tertiary ammonium (alkyl) acrylate dialkylaminoethyl ester, stir in vacuum, pass nitrogen, and heat up to 40°C;

[0047] Step 2, under the conditions of continuous stirring and nitrogen flow, start to slowly add 19g of quaternized alkyl acrylate dialkylaminoethyl ester dropwise, add redox initiator potassium persulfate and sulfite which are equivalent to 0.35% of the total mass of monomers 0.0311g of sodium bisulfate mixture initiates the copolymerization of two monomers, and keeps warm for 4h;

[0048] Step 3, heat up to 80°C, add 0.0165g of water-soluble azo initiator azobisisobutylamidine hydrochloride equivalent to 0.05% of the total mass of monomers, continue to react for 4h, cool to nor...

Embodiment 3

[0050] Step 1. In a 250mL four-neck reactor equipped with a thermometer, a nitrogen device and an agitator, add 62g of distilled water, 5g of itaconic acid (salt) and 3g of sodium hydroxide, then add 0.0405g of sodium hexamethylenediaminetetraacetate , start stirring, then add 9 g of tertiary ammonium (alkyl) acrylate dialkylaminoethyl ester, stir in vacuum, pass nitrogen, and heat up to 40 ° C;

[0051] Step 2, under the conditions of continuous stirring and nitrogen flow, start to slowly add 31g of quaternized alkyl acrylate dialkylaminoethyl, add redox initiator potassium persulfate and sulfite equivalent to 0.4% of the total mass of the monomer 0.0464g of the sodium bisulfate mixture initiates the copolymerization of the two monomers and keeps the temperature for 4h;

[0052] Step 3, heat up to 80°C, add 0.0228g of water-soluble azo initiator azobisisobutylamidine hydrochloride equivalent to 0.05% of the total mass of monomers, continue to react for 4h, cool to normal temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com