Patents

Literature

136results about How to "Compliant with Green Chemistry Requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing amino acid schiff base metal complexes without solvent

InactiveCN101811919AReduce usageCompliant with Green Chemistry RequirementsAmino group formation/introductionImino compound preparationBenzaldehydePotassium hydroxide

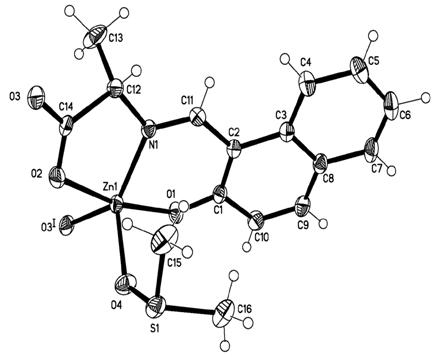

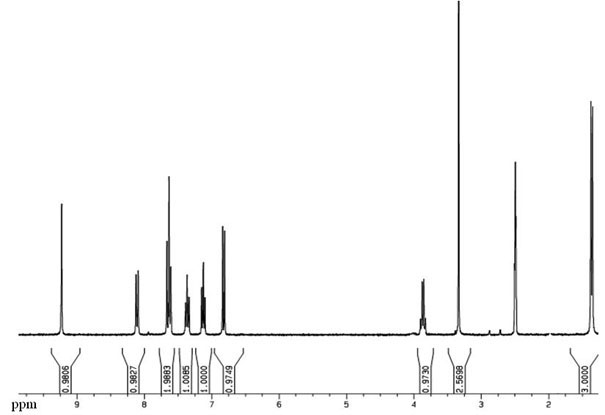

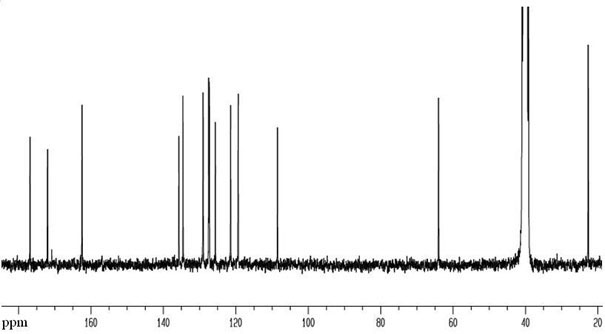

The invention discloses a method for preparing amino acid schiff base metal complexes without solvent, and relates to a method for preparing the amino acid-Schiff base metal complexes. The invention solves the problems of high solvent consumption and long reaction time in the conventional method for preparing the amino acid schiff base metal complexes. The method comprises the following steps of: 1, under the anhydrous condition, mixing L-amino acid, ortho-hydroxy-benzaldehyde and potassium hydroxide, and grinding for 2 to 5 minutes to obtain amino acid schiff base; and 2, adding bivalent copper salt or bivalent zinc salt into the amino acid schiff base obtained in the step 1, and grinding for 3 to 6 minutes to obtain the amino acid schiff base metal complexes, wherein the step 1 and the step 2 are all completed at room temperature. The whole preparation process needs only 5 to 11 minutes, the reaction time is short, the solvent is not needed, the process is simple, the work efficiency is high, the posttreatment is simple and the yield reaches 80 to 95 percent.

Owner:HARBIN UNIV OF SCI & TECH

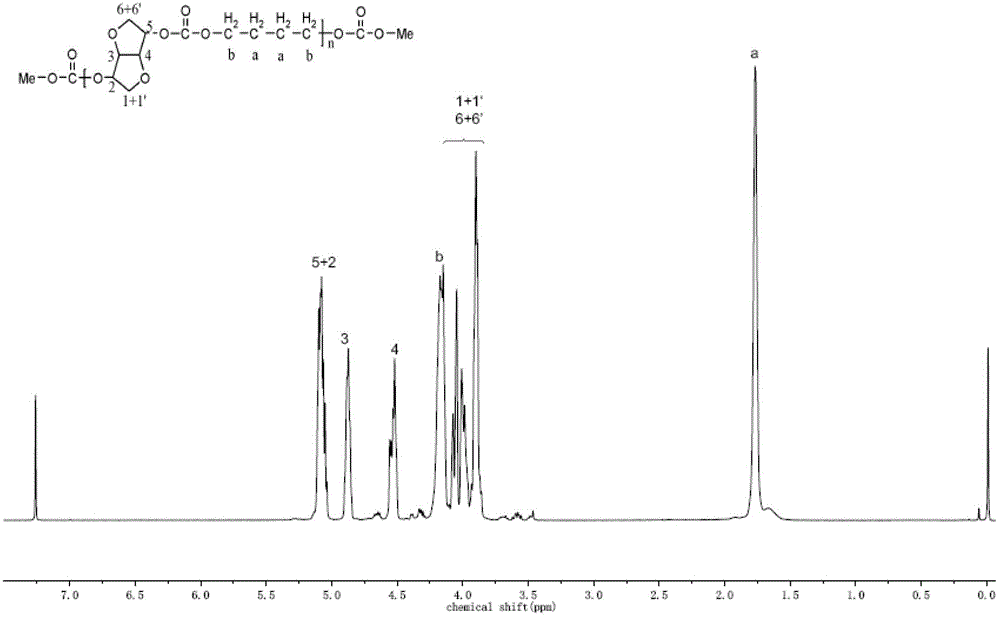

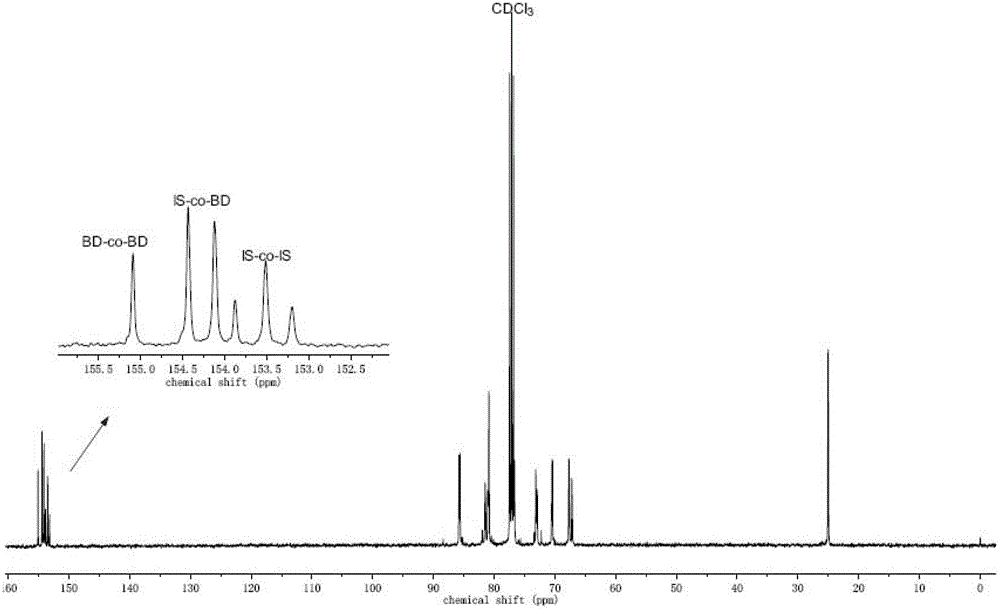

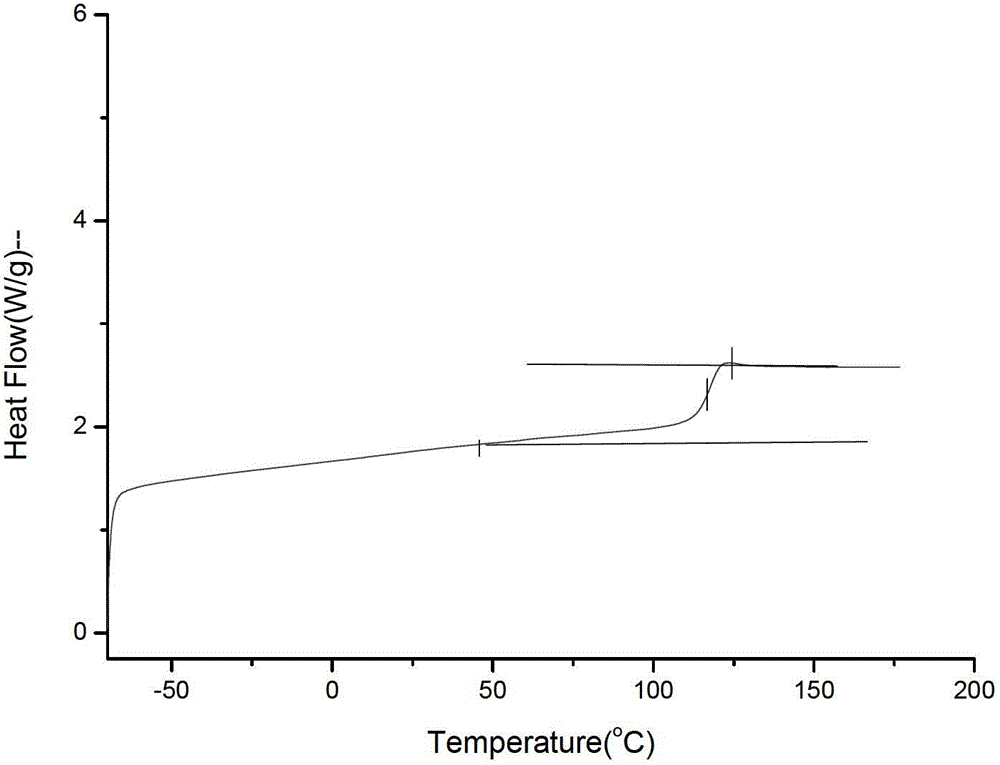

High-heat resistant aliphatic polycarbonate based on 1,4:3,6-dianhydro-hexanehexol, and preparation method and application thereof

The invention discloses high-heat resistant aliphatic polycarbonate based on 1,4:3,6-dianhydro-hexanehexol, and a preparation method and application thereof. According to the method, 1,4:3,6-dianhydro-hexanehexol and aliphatic diol respectively react with, or are mixed and then react with carbonic ester under the action of a catalyst in an inert gas atmosphere to realize ester interchange, and a resultant prepolymer undergoes polycondensation under the action of a polycondensation catalyst so as to obtain a product. The method costs little, can effectively improve transparency and the color of 1,4:3,6-dianhydro-hexanehexol type polycarbonate, uses a small amount of catalysts during reaction process and avoids complex separating process for the catalysts. The obtained product is a colorless or faint yellow transparent solid and has a number-average molecular weight of 1.5*10<4> to 2.0*10<5> and a glass-transition temperature of 100 to 175 DEG C. Prepared from biological raw materials and aliphatic diol, the product does not contain any residual phenyl ring and has no toxicity, usable as a food package material like a water cup and a water bottle or as a medical material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

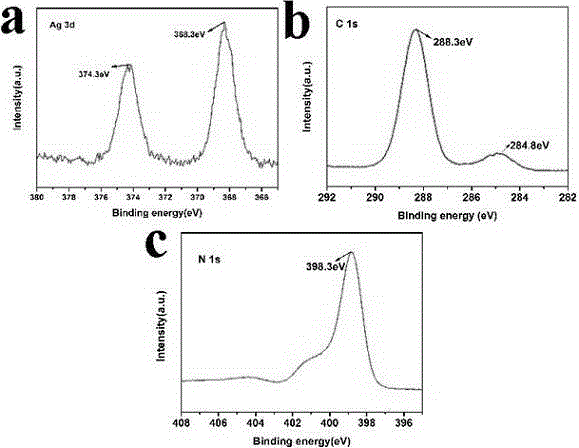

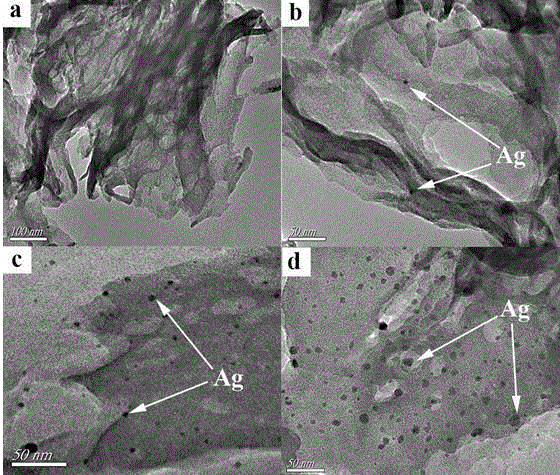

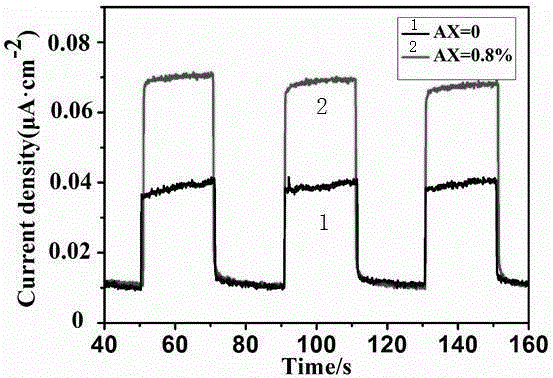

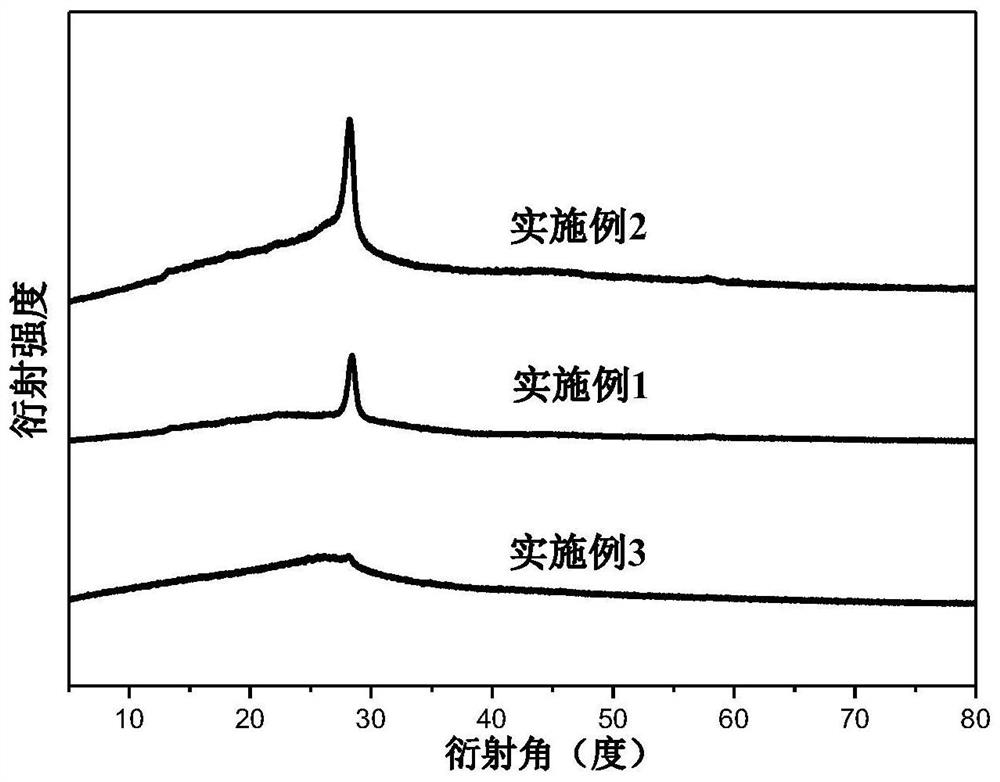

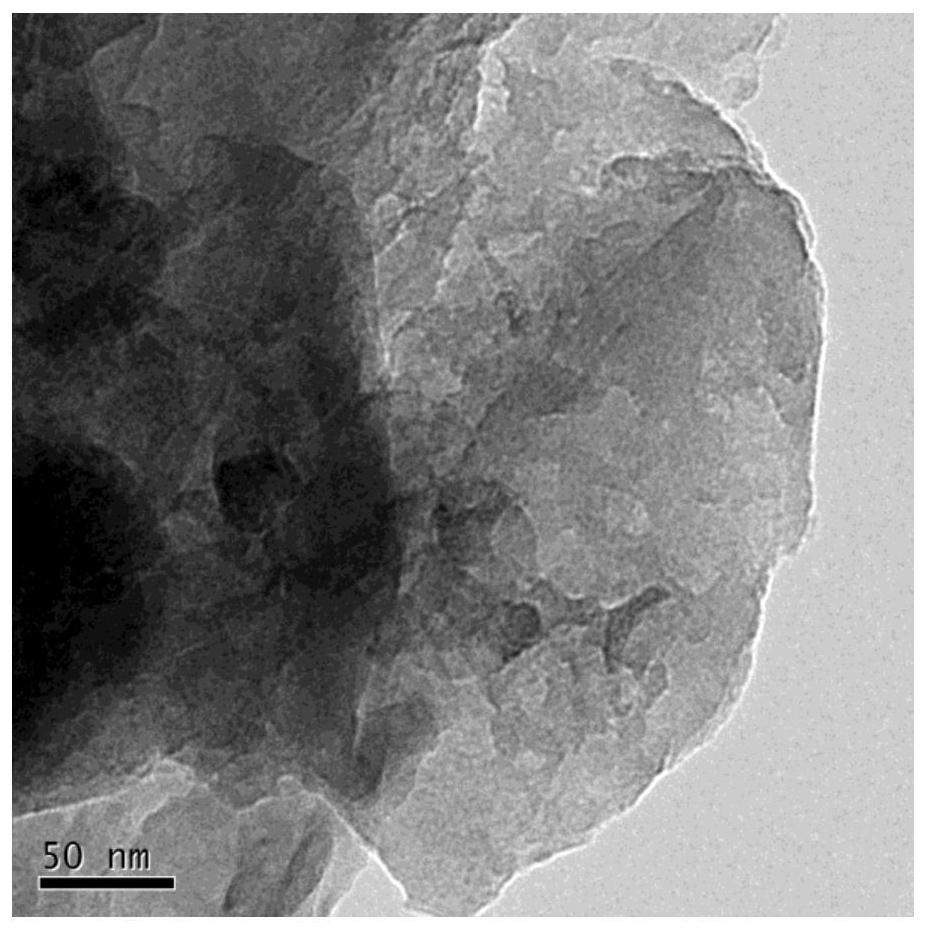

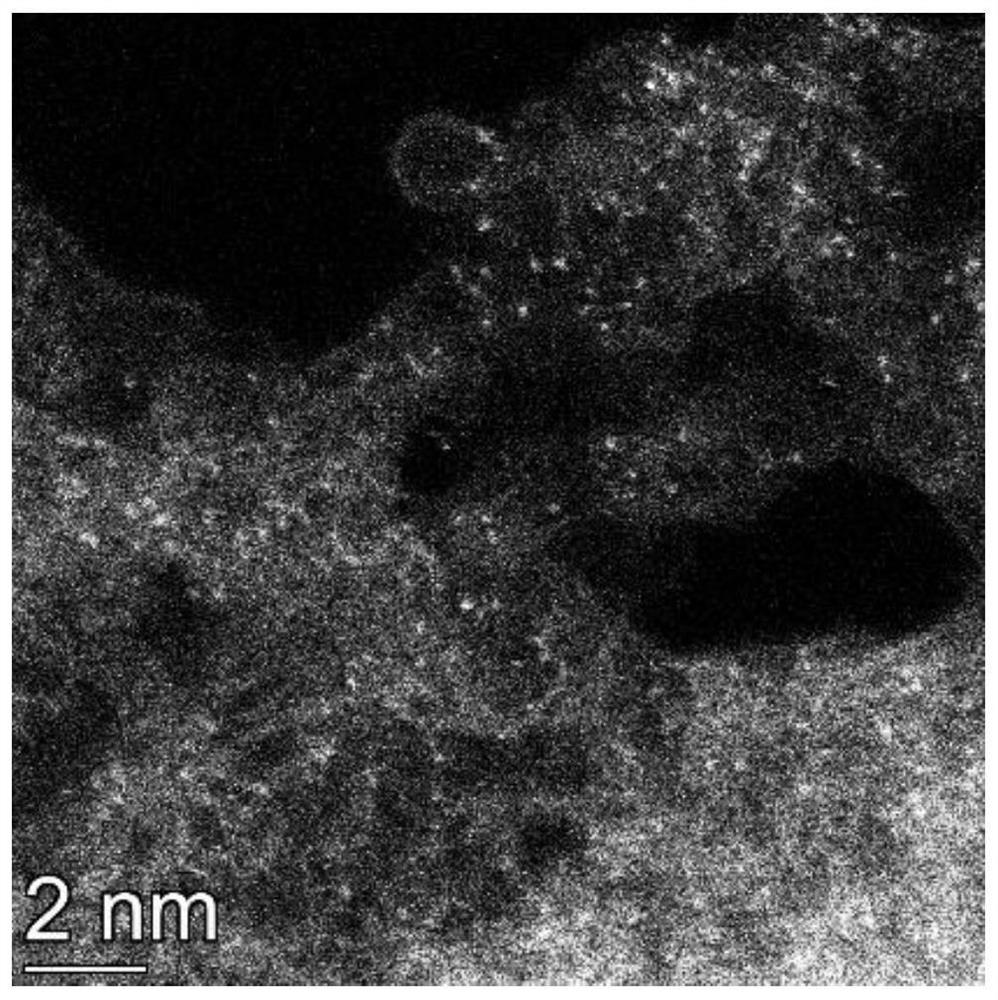

Method for preparing Ag/g-C3N4 catalyst

InactiveCN105214711AGood chemical stabilityHigh chemical activityPhysical/chemical process catalystsHydrogen productionPtru catalystPhysical chemistry

The invention relates to a carbon-based material g / C3N4, and particularly relates to a method for synthesizing a g / C3N4 composite material modified by Ag quantum dots through in-situ synthesis. The method is characterized by comprising the following steps of weighing urea, dissolving in distilled water, and performing ultrasonic treatment, so as to obtain a solution A; adding quantitative AgNO3 to the solution A, and stirring in the air, so as to obtain a solution B; heating the obtained solution B in water bath, continuously stirring to dry, and then drying, so as to obtain a sample C; putting the sample C into a muffle, guaranteeing the initial temperature of the muffle to be less than 80 DEG C so as to obtain porous g-C3N4, heating the muffle to 550 DEG C, and keeping the temperature for 4 hours, so as to obtain a sample D; naturally cooling to room temperature, washing and drying the sample D, so as to obtain the g-C3N4 modified by the Ag quantum dots, which can be used for hydrogen generating reaction by water photolysis.

Owner:JIANGSU UNIV

Iron-nitrogen-carbon composite material containing monatomic active sites as well as preparation and application methods of iron-nitrogen-carbon composite material

ActiveCN113042081AImprove degradation efficiencyLow dissolution ratePhysical/chemical process catalystsWater/sewage treatment by oxidationCarbon compositesIron phthalocyanine

The invention provides an iron-nitrogen-carbon composite material containing monatomic active sites, which comprises a carrier containing graphite-like carbon nitride and iron monatomic combined with the carrier, so that the catalytic activity to peroxymonosulfate is improved, and a large amount of metal ions are prevented from being dissolved out. The preparation method comprises the following steps: S1, dissolving a nitrogen-containing carbon source in an ethanol solution to obtain a solution A; wherein the nitrogen-containing carbon source is prepared from one or more of melamine, dicyandiamide and urea; S2, dispersing an iron-containing metal precursor in the solution A, and then performing evaporation to dryness treatment to obtain a mixed substance B; wherein the iron-containing metal precursor comprises one or two of chlorhematin and iron phthalocyanine; and S3, sequentially performing grinding and mixing treatment, pyrolysis treatment and cooling treatment on the mixed substance B, sequentially performing acid pickling treatment, water washing treatment and drying treatment on a substance obtained after cooling treatment, and obtaining the iron-nitrogen-carbon composite material.

Owner:CENT SOUTH UNIV

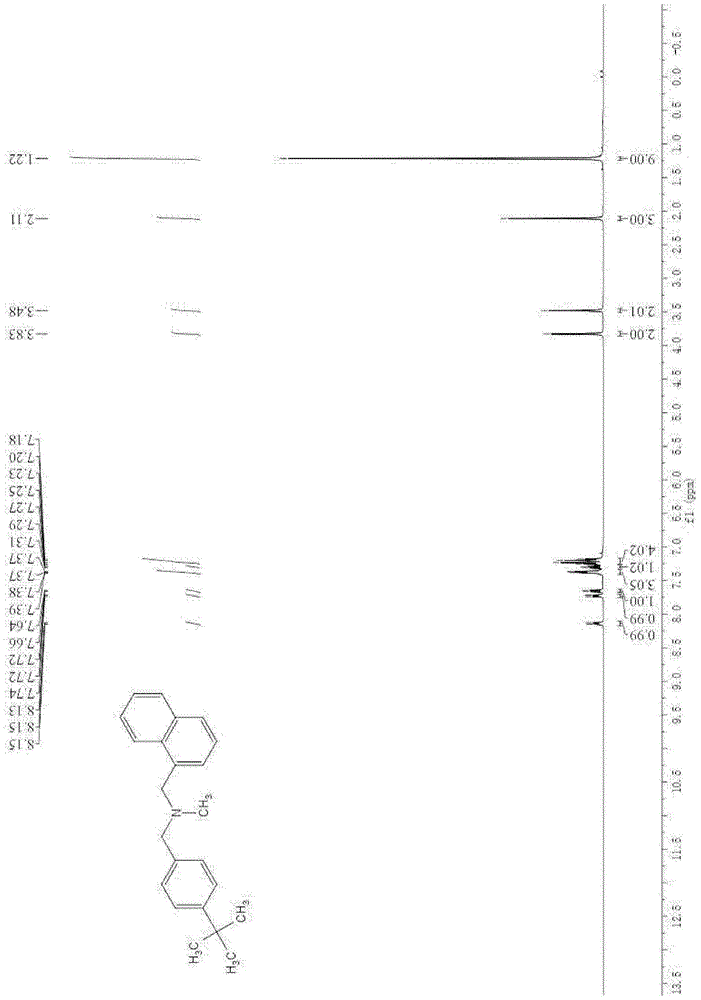

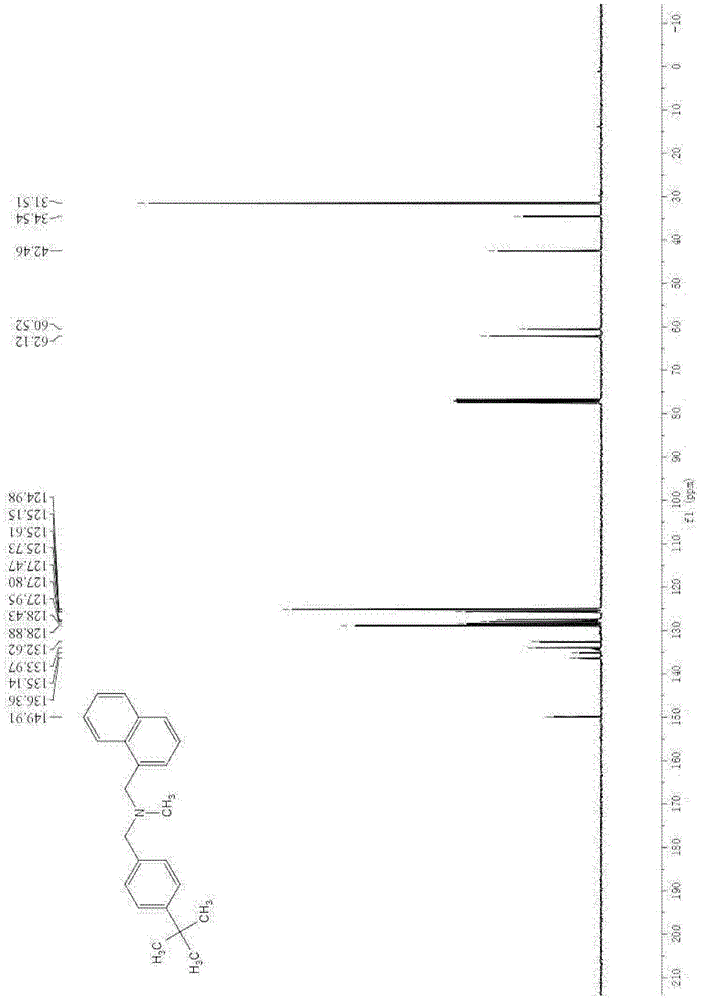

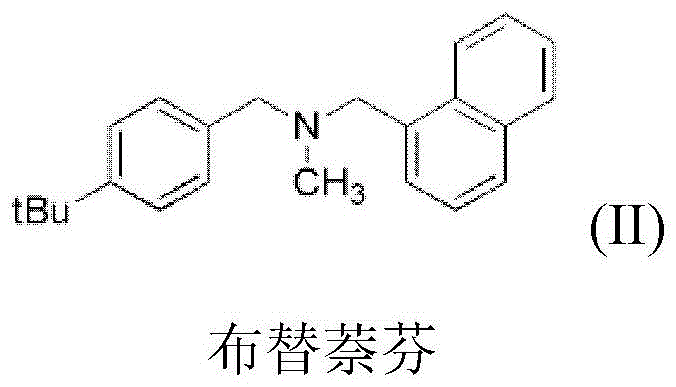

A kind of method of synthesizing butenafine

InactiveCN105130823BWide variety of sourcesAvoid residueOrganic compound preparationAmino compound preparationSynthesis methodsTwo step

The present invention discloses a butenafine synthesis method, the butenafine is shown as formula II, a desired product is prepared from 4-tert-butyl-benzylamine, 1-naphthoyl chloride, and formic acid as starting materials by amidation and reductive methylation two-step method by use of a non-metallic boron compound as a catalyst and an organic silane compound as a reducing agent, the butenafine synthesis method is simple, easy to operate, wide in source of raw materials, and low in cost; and a metal catalyst is not required to participate in the synthesis, the metal residues in the medicine can be avoided, and the method is safe, environmentally-friendly, and in line with the requirements of green chemistry.

Owner:UNIV OF SCI & TECH OF CHINA

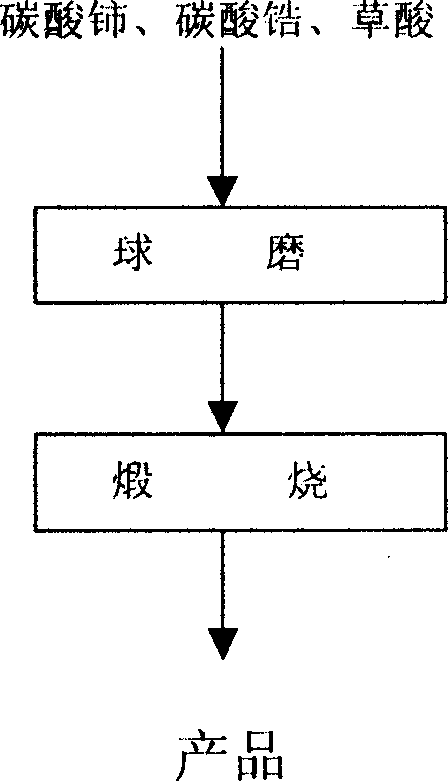

Medium-low temperature solid-solid reaction method for preparing nano grade cerium-zirconium composite oxide solid solution

InactiveCN1749171AGood dispersionLarge specific surface areaRare earth metal compoundsTitanium oxides/hydroxidesCeriumSolvent

The present invention is medium and low temperature solid-solid reaction process for preparing nanometer level composite cerium-zirconium oxide solid solution. The composite cerium-zirconium oxide solid solution including cerium oxide and zirconium oxide is prepared with cerium carbonate and zirconium carbonate as material, and through adding oxalic acid in certain amount, mixing, ball milling and calcining. The composite cerium-zirconium oxide solid solution has high crystallization degree, crystal grain size of 20-70 nm, and specific surface area of 80-100 sq m / g. The preparation process has the advantages of no solvent used, no effluent, simple operation, low power consumption, environment friendship, etc.

Owner:GUANGDONG UNIV OF TECH

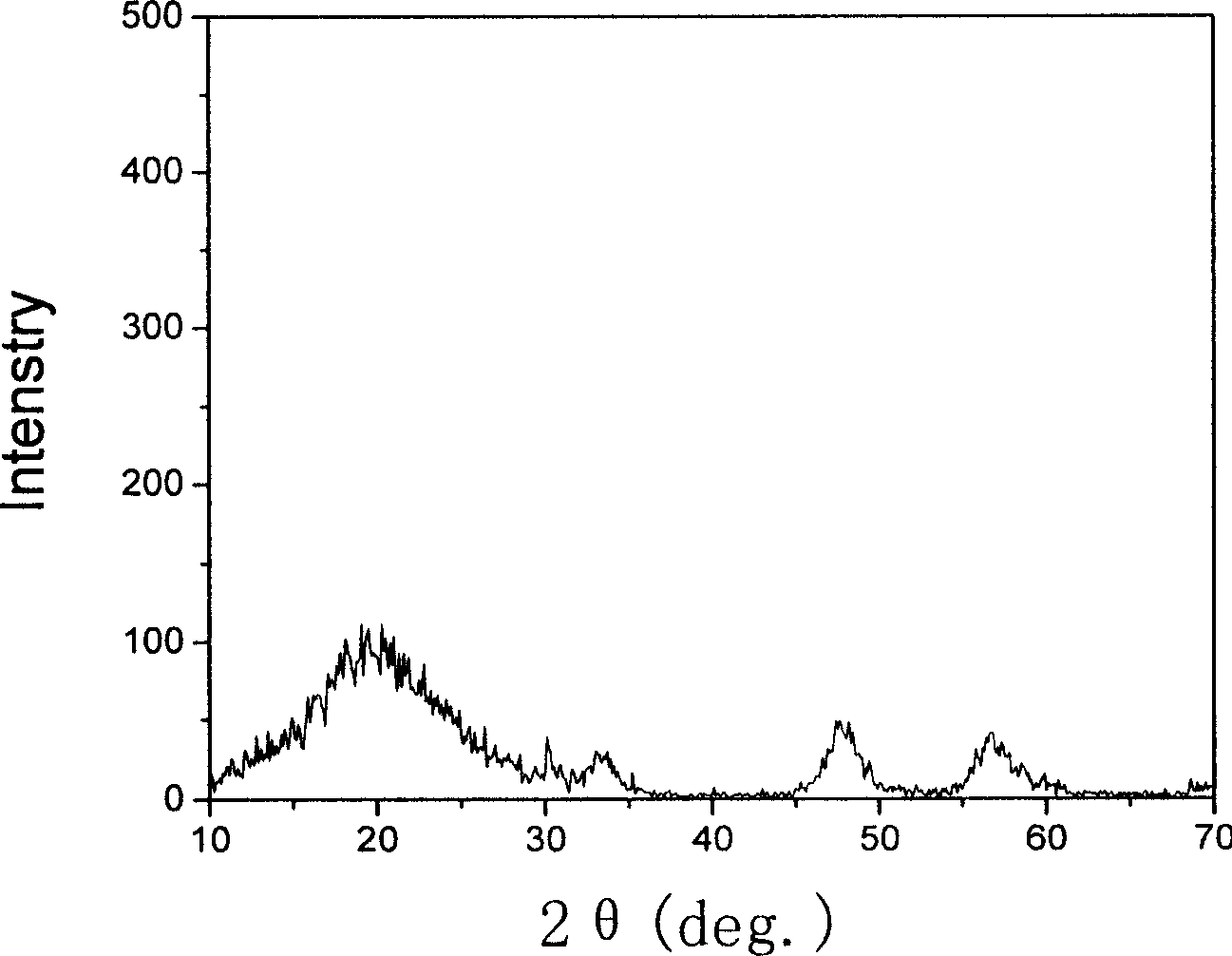

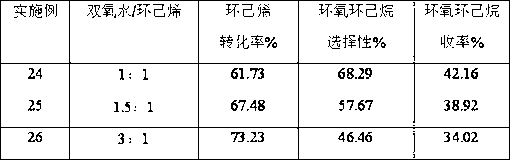

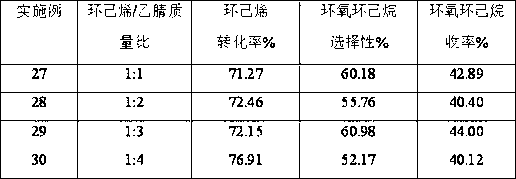

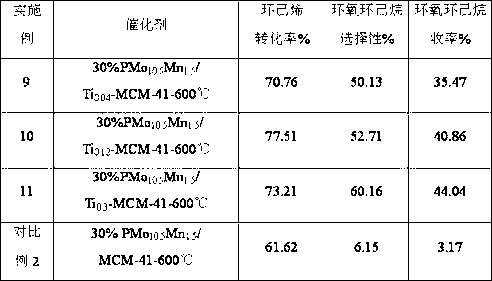

Method for preparing cyclohexene oxide

ActiveCN102786499AEasy to makeLow costOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsCyclohexene oxideOxygen

The invention discloses a method for preparing cyclohexene oxide, belonging to the technical field of a fine chemical product. The method comprises the steps of: taking cyclohexene as a substrate and acetonitrile as a reaction solvent, taking 30wt% of hydrogen peroxide as an oxidizing agent, carrying out olefin epoxidation under the action of a catalyst taking a Ti-MCM-41 mesoporous molecular sieve as a carrier to load phosphorus molybdenum iron composite oxide, rectifying the reaction liquid, and taking fraction at 130-135 DEG C to obtain cyclohexene oxide. The load type composite oxide disclosed by the invention has good catalytic activity, and can be repeatedly used; the hydrogen peroxide is used as an oxygen source in the reaction; a byproduct is water and accords with green chemical requirements; the condition is mild at constant pressure; reactant and the byproducts are easily separated; the reaction selectivity is good; the reaction energy consumption is low; and the demand on the reaction device is low; the obtained product cyclohexene oxide is easily separated, and the yield of the cyclohexene oxide is high.

Owner:平邑仁安中医药产业发展有限公司

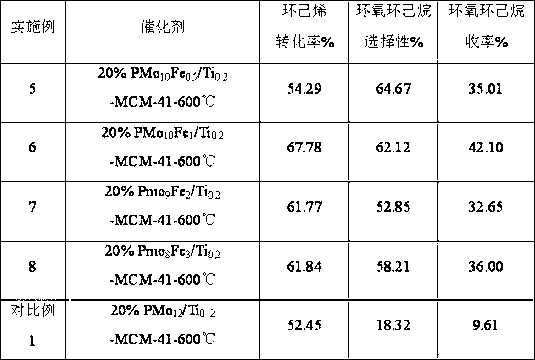

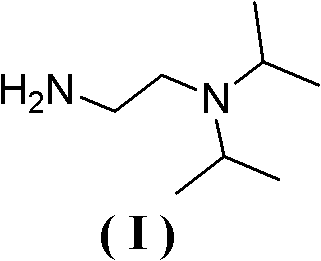

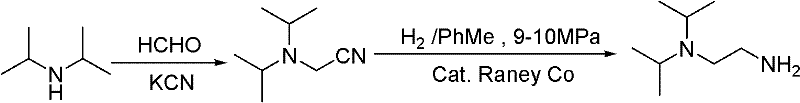

Synthesis method of N,N-diisopropyl quadrol

ActiveCN102249928ARaw materials are cheap and easy to getMild reaction conditionsPreparation by rearrangement reactionsSynthesis methodsDiisopropylamine

The invention discloses a synthesis method of N,N-diisopropyl quadrol. According to the synthesis method, N,N-diisopropyl quadrol is synthesized through Michael addition and Hoffmann degradation by taking acrylamide and diisopropylamine as starting raw materials. The synthesis method has the advantages of advanced process route, reasonable process condition, cheap and available raw materials, mild reaction conditions, high atom economy, low production cost and less three wastes, is simple and safe to operate, is suitable for industrial production, and has a large implementation value and large social and economic benefits.

Owner:ZHEJIANG UNIV OF TECH +1

Method for producing 5-hydroxymethyl furfural by chitin biomass

ActiveCN103121984AWide variety of sourcesRich reservesOrganic chemistryChlorideHydroxymethylfurfural

The invention discloses a method for producing 5-hydroxymethyl furfural by chitin biomass. The method comprises the steps of preparing a zinc chloride water solution of which mass concentration is 30-72%; evenly mixing the dried chitin biomass material, the zinc chloride water solution and a catalyst; reacting for 10 minutes to 10 hours after the reaction is finished at 60-140 DEG C, wherein the mass ratio of the chitin biomass material to the zinc chloride water solution is 1: (3-180); the mass ratio of the added catalyst to the chitin biomass material is 1: (1-50); extracting the 5-hydroxymethyl furfural from a reaction system by an organic extracting agent after the reaction is finished; then concentrating and drying the extracting agent, and crystallizing to obtain the 5-hydroxymethyl furfural product. The method has the advantages of being wide in source of the chitin biomass, abundant in storage, simple in operation process and high in obtained product purity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

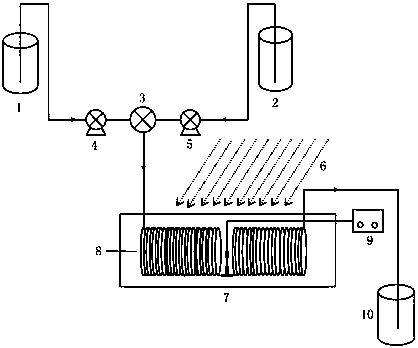

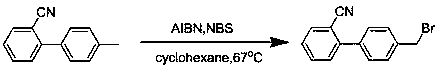

Method for tubular reaction preparation of substituted benzylically brominated methyl biphenyl and reaction device of method

InactiveCN107935956AEasy reaction controlImprove securityCarboxylic acid nitrile preparationOrganic compound preparationBromineSolvent

The invention discloses a method for tubular reaction preparation of substituted benzylically brominated methyl biphenyl and a reaction device of the method. According to the method, substituted methyl biphenyl is taken as a raw material and bromine is taken as a bromination reagent. The reaction materials are continuously fed into a high-efficiency mixer for mixing through a liquid conveying pump, and the formed mixture enters a reactor in a water bath for a reaction, after the reaction is finished, the reaction system enters a receiving tank, a reducing agent is added to the receiving tank for quenching, liquid separation is carried out, anhydrous sodium sulfate is added into the organic phase, suction filtration is performed, the organic phase is subjected to reduced-pressure concentration for solvent removal, a solvent is added for recrystallization, suction filtration is performed, and the filter cake is dried to obtain a pure product namely the substituted benzylically brominatedmethyl biphenyl. The method of the invention is simple and convenient to control, high in safety, less in generation of by-products and convenient for post-processing, a small trial process can be directly used for amplified production. The method meets the requirements of green chemistry and has a certain industrial application value.

Owner:ZHEJIANG UNIV OF TECH

Biomass carbonization treatment method

ActiveCN108893128AAbundant sources of raw materialsLow priceBiofuelsSpecial form destructive distillationSolventChemistry

The invention discloses a biomass carbonization treatment method, and belongs to the field of waste resource utilization. The biomass carbonization treatment method includes steps of (1), drying and smashing biomass to obtain biomass powder; (2), mixing and then heating the biomass powder, acid and catalysts with one another, and completely carbonizing biomass to obtain mixtures; (3), cooling themixtures generated at the step (2) until the temperatures of the mixtures reach the room temperature, adding solvents into the mixtures, carrying out stirring and washing until the acid adsorbed in charcoal is completely dissolved out, and carrying out drying to obtain biomass charcoal and diluted acid or salt. The biomass carbonization treatment method has the advantages that resource recycling and utilization can be carried out on the biomass by the aid of the biomass carbonization treatment method, the biomass carbonization treatment method is high in biomass charcoal yield, charcoal emission can be obviously reduced, and the biomass charcoal obtained by the aid of the biomass carbonization treatment method has an extremely high application value; the biomass carbonization treatment method includes few reaction steps and is low in energy consumption, low-cost carbonization treatment can be carried out on the biomass by the aid of the biomass carbonization treatment method, and the requirements of green chemistry can be met by the biomass carbonization treatment method.

Owner:BEIJING ZFRK ENVIRONMENT &TECH CO LTD

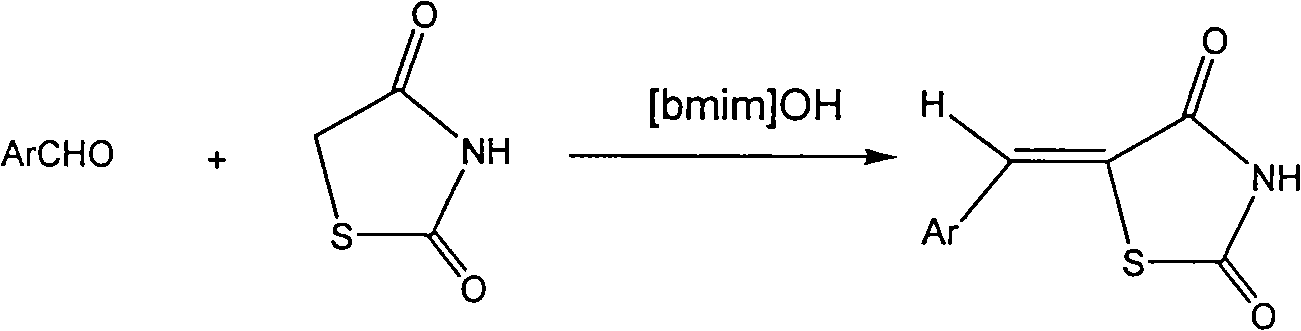

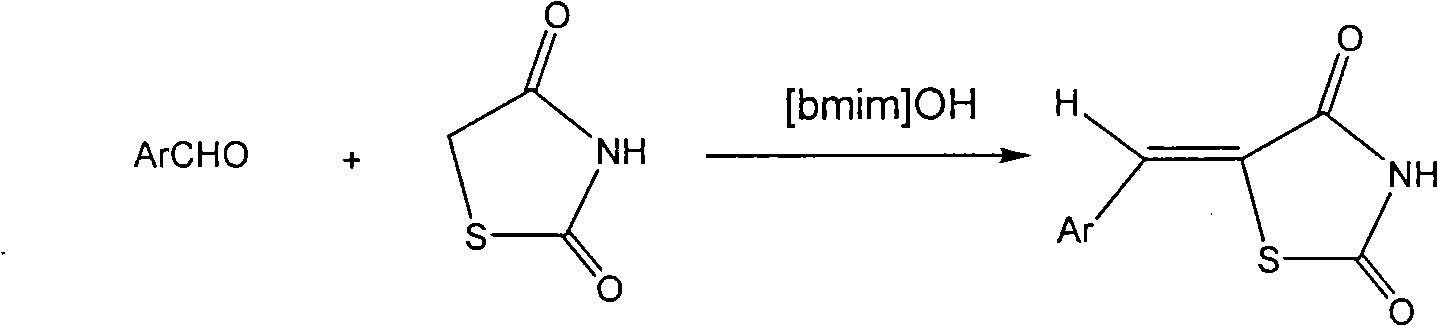

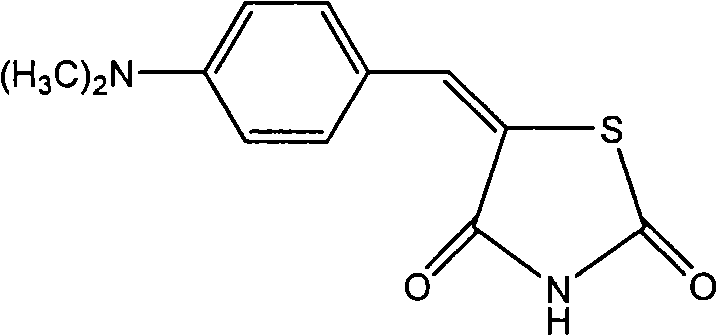

Method for preparing tetrahydrothiazole diketone derivatives

InactiveCN101293877APlay a double roleThe nature of the environment is stableOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsDiketoneThiazolidinedione

The invention discloses a method for preparing thiazolidinedione derivatives using an aromatic aldehyde and 2,4-thiazolidinedione as raw materials, ionic liquid [Bmim]OH as catalyst and solvent. The preparation method has the advantages of simple process operation, short reaction time, no pollution, and fulfillment of green chemistry requirements. The obtained product can be simply separated, and has yield of 85-92% and purity up to over 98%.

Owner:NANJING UNIV OF TECH

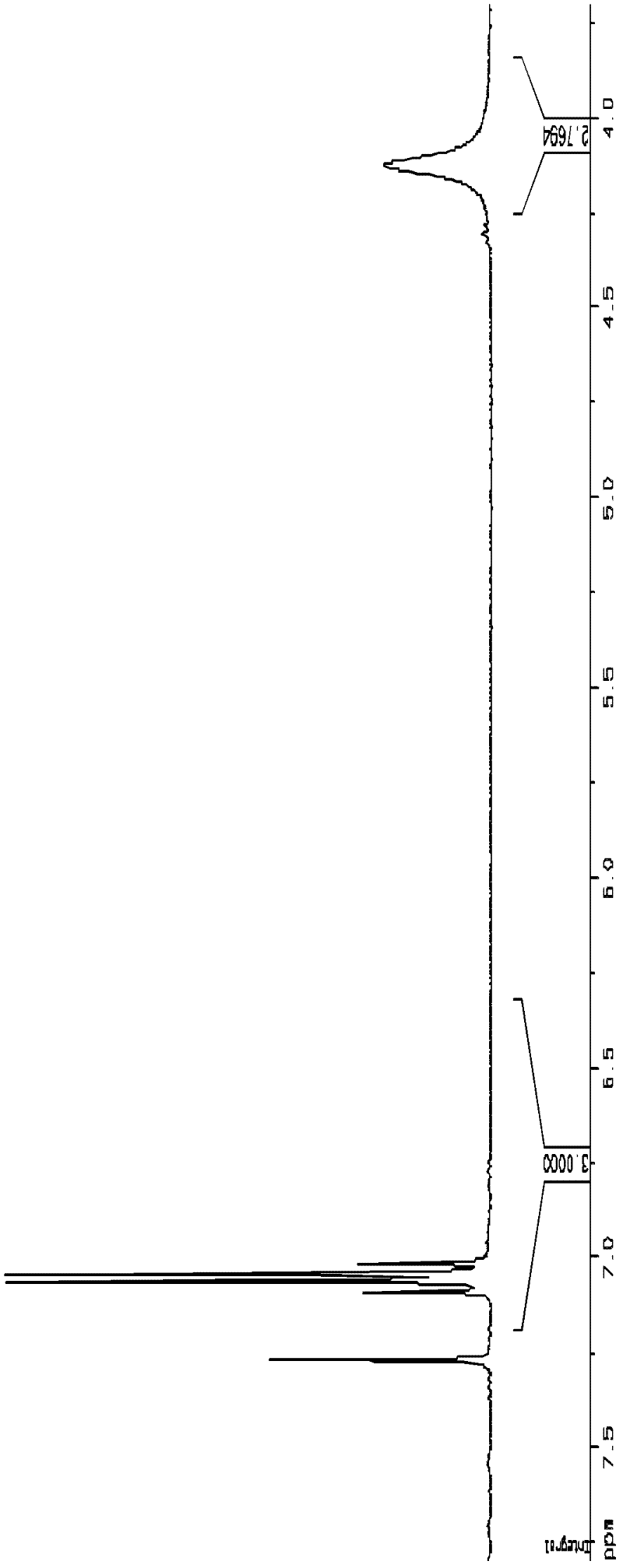

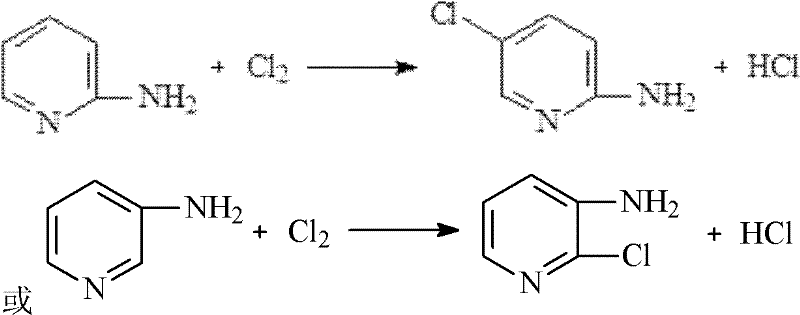

Preparation method of aminopyridine chloride

InactiveCN102358944ALess by-productsHigh product purityElectrolysis componentsElectrolytic organic productionChemistryHigh selectivity

The invention discloses a preparation method of an aminopyridine chloride, relating to the field of preparation of the aminopyridine chloride and aiming to solve the problems of low product yield, more byproducts in products, complex operation process and serious environment pollution in the traditional aminopyridine synthesis process. The preparation method comprises the following steps of: 1, electrolyzing, and 2, separating and purifying. The preparation method disclosed by the invention has the advantage of: 1, very high selectivity, fewer byproducts in the products, high product purity and simplicity for postprocessing; 2, simplicity for operation, no need of any catalysts, mild reaction conditions and low energy consumption; 3, reduced consumed energy for reaction due to adoption of a diaphragm-free electrolytic cell; 4, capability of meeting requirements of green chemistry for environment friendliness; and 5, production safety. The preparation method disclosed by the invention is mainly used for preparing 2-amino-5-chloropyridine and 3-amino-2-chloropyridine.

Owner:HARBIN UNIV OF SCI & TECH

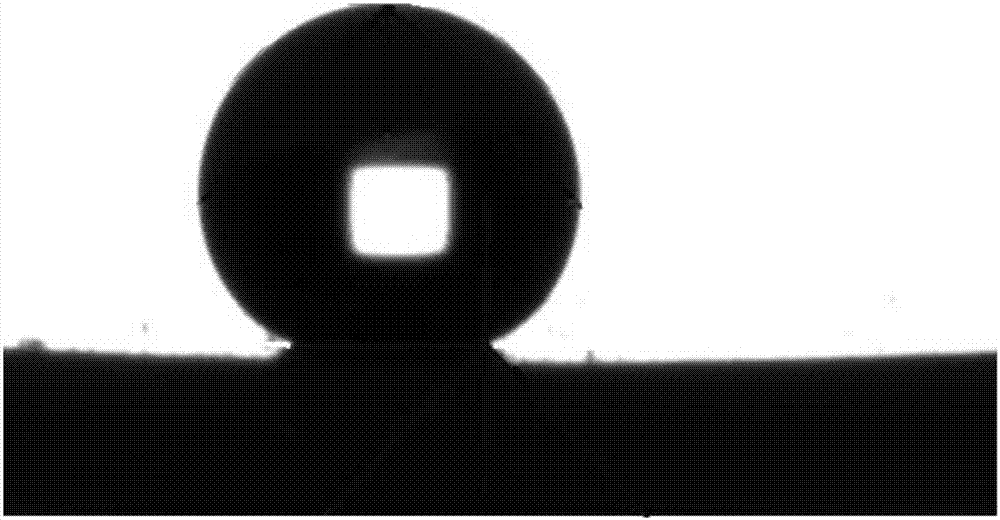

A method of preparing a hydrophobic type silicon dioxide aerogel material and a method of preparing a VIP vacuum plate and powder

The invention provides a method of preparing a hydrophobic type silicon dioxide aerogel material and a method of preparing a VIP vacuum plate and powder, and relates to the field of aerogel materials. The methods overcome a problem that sol-gel preparing cycles are long and the most difficult problem that is tedious solvent displacement in aerogel material preparation. The method of preparing the hydrophobic type silicon dioxide aerosol material includes mixing a silicon source and an acid solution having a certain concentration to prepare a gel precursor, adding an organic extractant, and performing extraction to obtain the hydrophobic type SiO2 aerogel material. The methods are applied in the field of aerogel materials.

Owner:江西宏柏新材料股份有限公司

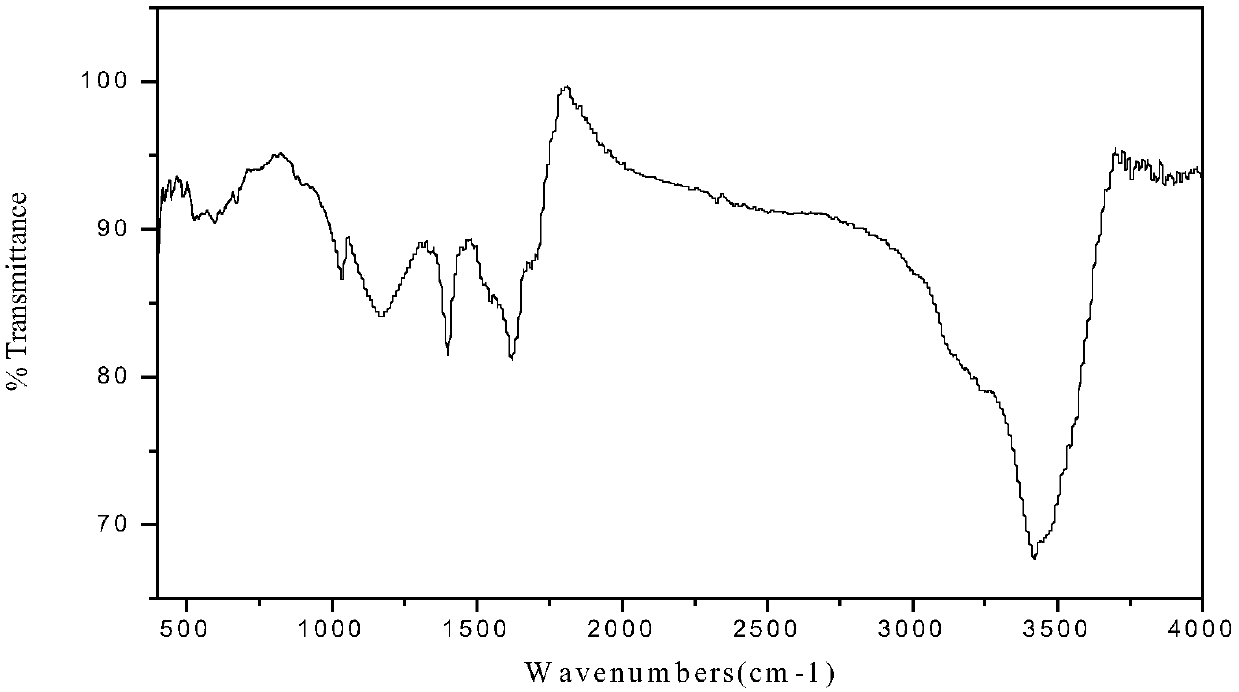

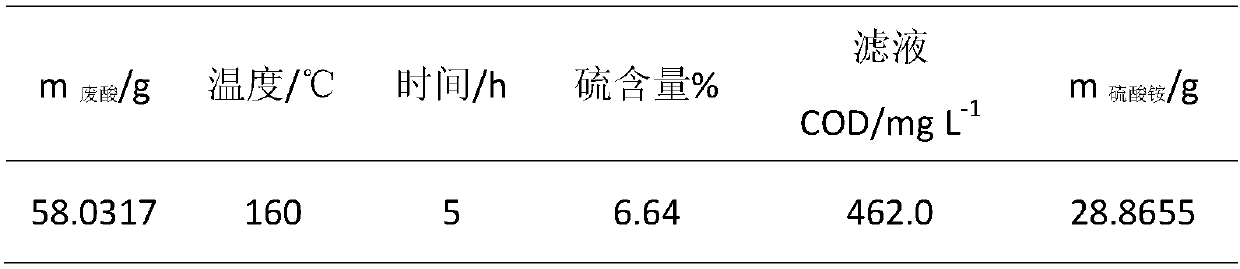

Method for preparing carbon-based acid material by means of alkylated waste acid

ActiveCN107754816AStrong acidReduce organic contentOrganic-compounds/hydrides/coordination-complexes catalystsAmmonium hydroxideOrganic matter

The invention relates to a method for preparing a carbon-based acid material by means of alkylated waste acid. The method comprises the following steps that the alkylated waste acid is heated to reachthe temperature of 100-500 DEG C, the temperature is kept for 1-10 h, products are washed to be neutral with a solvent, drying is conducted at 60-200 DEG C, and the carbon-based acid material is obtained, wherein the solvent obtained after washing basically does not contain organic matter, and the solvent is at least one of water, dilute sulfuric acid, ammonium hydroxide and ammonium sulfate. Themethod for preparing the carbon-based acid material is short in process route, small in investment, easy to operate, low in running cost and wide in application range, resource recycling of acid soluble oil and sulfuric acid in waste sulfuric acid can be achieved, and carbon emission is reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for producing synthetic gas by reforming by-product glycerin vapor of biological diesel production

InactiveCN101062762AEasy to makeEasy to operateHydrogenBulk chemical productionSteam reformingSyngas

The invention discloses a preparing method of synthetic gas through reforming the by-product glycerin steam of biological diesel in the preparing technology of synthetic gas, which comprises the following steps: filling Ni / ZrO2 or Ni / CeO2 or Ni / CeO2-ZrO2 activator into reactor; setting the content of nickel at 10%-15%; adopting hydrogen gas and nitrogen gaseous mixture; proceeding reducing pre-treatment for the activator; leading glycerin water solution steam into the reactor with air speed at 5000-20000h-1 and ratio of water and carbon at 1:1-5:1; steam-reforming under normal pressure and with temperature at 300-600 deg. c; preparing the product. This invention possesses the advantages of simple craft course, low cost and wide prospect, which is fit for the requirement of green chemistry.

Owner:TIANJIN UNIV

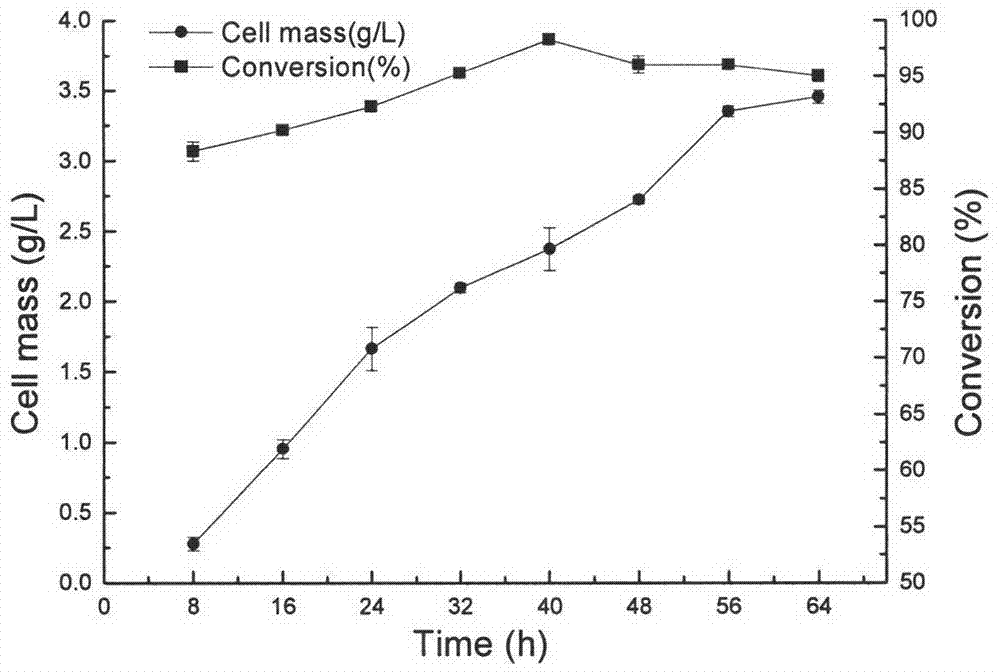

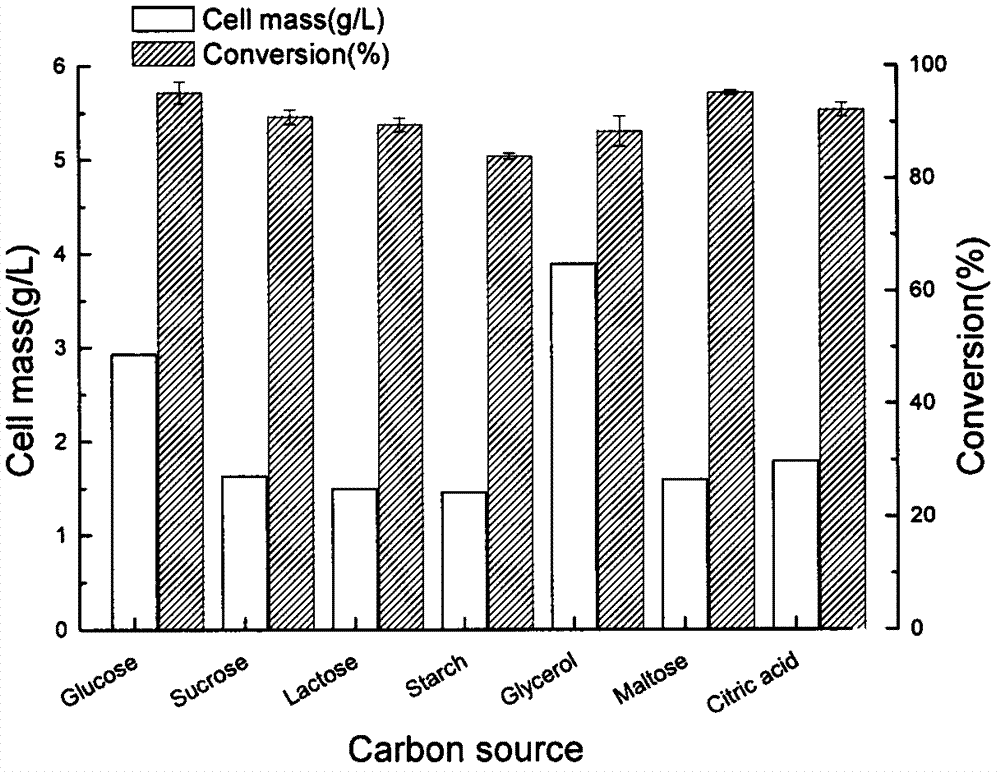

Nocardia sp. capable of converting quininone into (R)-3-quinuclidinol and conversion method

ActiveCN102952761AEasy to trainHigh yieldBacteriaMicroorganism based processes3-quinuclidinolGreen chemistry

The invention discloses a Nocardia sp. WY1202 and a production method for (R)-3-quinuclidinol through fermentation of quininone by using Nocardia sp. WY1202. According to the invention, quininone hydrochloride is used as a sole carbon source for the strain of Nocardia sp. WY1202 which is screened from soil in a farm orchard in Xiqing District, Tianjin City, China, and is preserved in China General Microbiological Collection Center with an accession number of CGMCC No. 5095. The production method comprises the following steps: with the Nocardia sp.WY1202 as a strain, carrying out primary seed culture and secondary fermentation amplification culture; taking a fermentation culture solution, collecting thalli through centrifugation, washing the thalli and re-suspending the thalli in a buffer solution; adding the substrate quininone hydrochloride, adding glucose and carrying out centrifugation after a reaction for 24 to 48 h; adjusting the pH value of a supernatant until the supernatant is alkaline; drying the supernatant through pressure reduced spinning; subjecting an obtained residue to solid-liquid extraction with an organic solvent; and drying an obtained filtrate through spinning so as to obtain (R)-(-)-3-quinuclidinol. According to the invention, the product (R)-(-)-3-quinuclidinol has a yield of 95%, a purity of 96% and an e.e value of more than 95%; the production method is simple to operate, has low energy consumption, accords with requirements for green chemistry and is applicable to large-scale bioconversion production for (R)-(-)-3-quinuclidinol.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

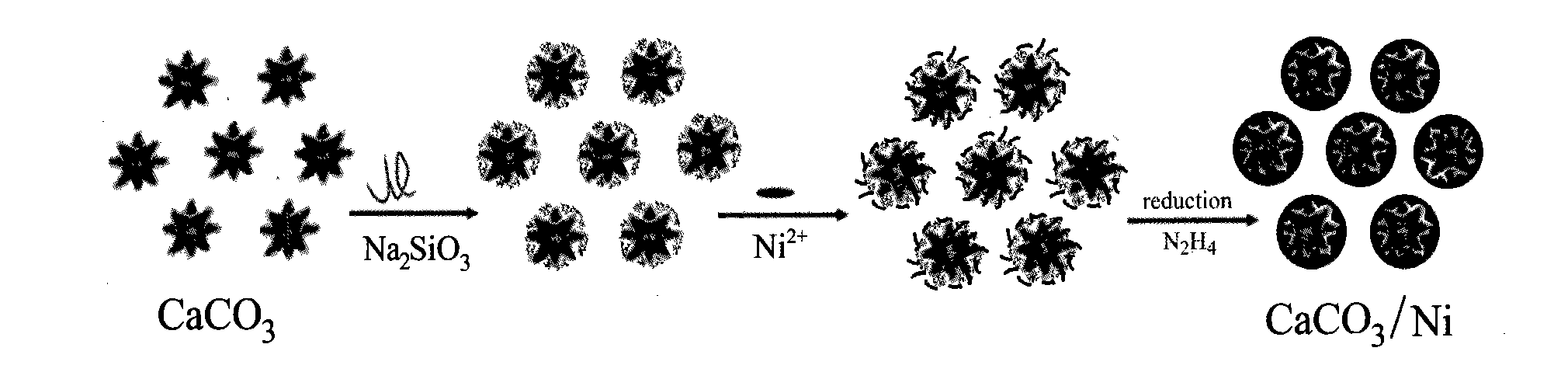

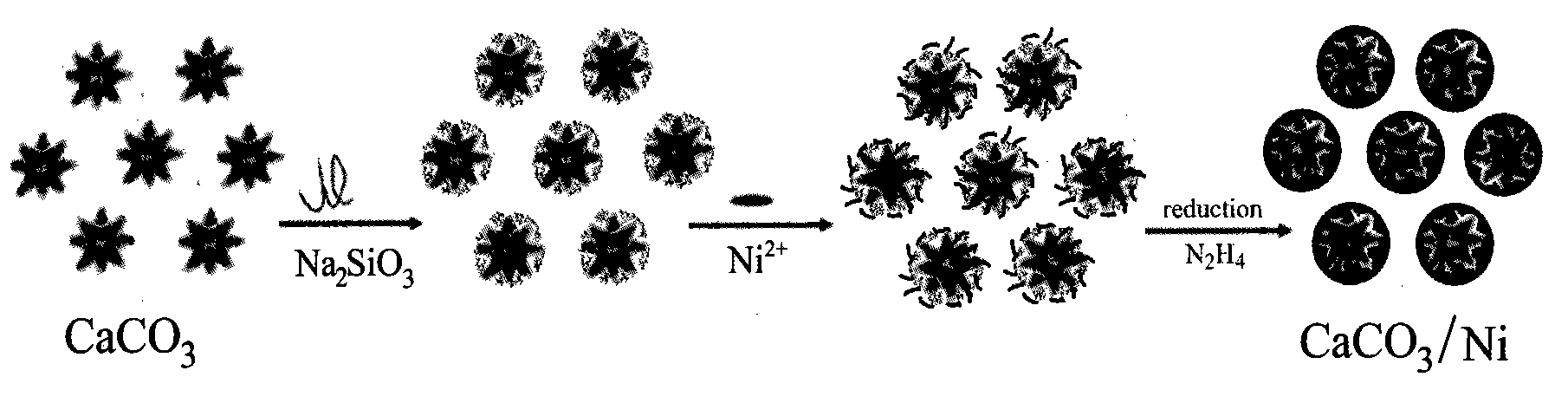

Calcium carbonate/nickel composite conductive powder and preparation method thereof

ActiveCN101923907AFulfil requirementsGood dispersionConductive materialAntistatic MaterialsChemical stability

The invention discloses a calcium carbonate / nickel composite conductive powder and a preparation method thereof. The calcium carbonate / nickel composite conductive powder is prepared by a method of performing in-situ reduction on the surface of a calcium carbonate nano-assembled sphere. The method comprises the following steps of: putting the corresponding calcium carbonate nano-assembled sphere and a nickel source into a reactor, taking water as a medium, adding a proper amount of coupling agent, and adjusting the temperature and a pH value of the system to make the system perform the in-situ reduction; and after full reaction, performing the treatment processes such as filtering, washing, drying and the like on the obtained product to prepare the calcium carbonate / nickel composite conductive powder. The prepared conductive powder has the advantages of high dispersibility, small particle size, uniform size distribution, excellent conductivity, high chemical stability and the like, and can be widely applied to the fields of antistatic materials, anticorona coatings and the like.

Owner:池州市贵兴非矿新材料有限公司

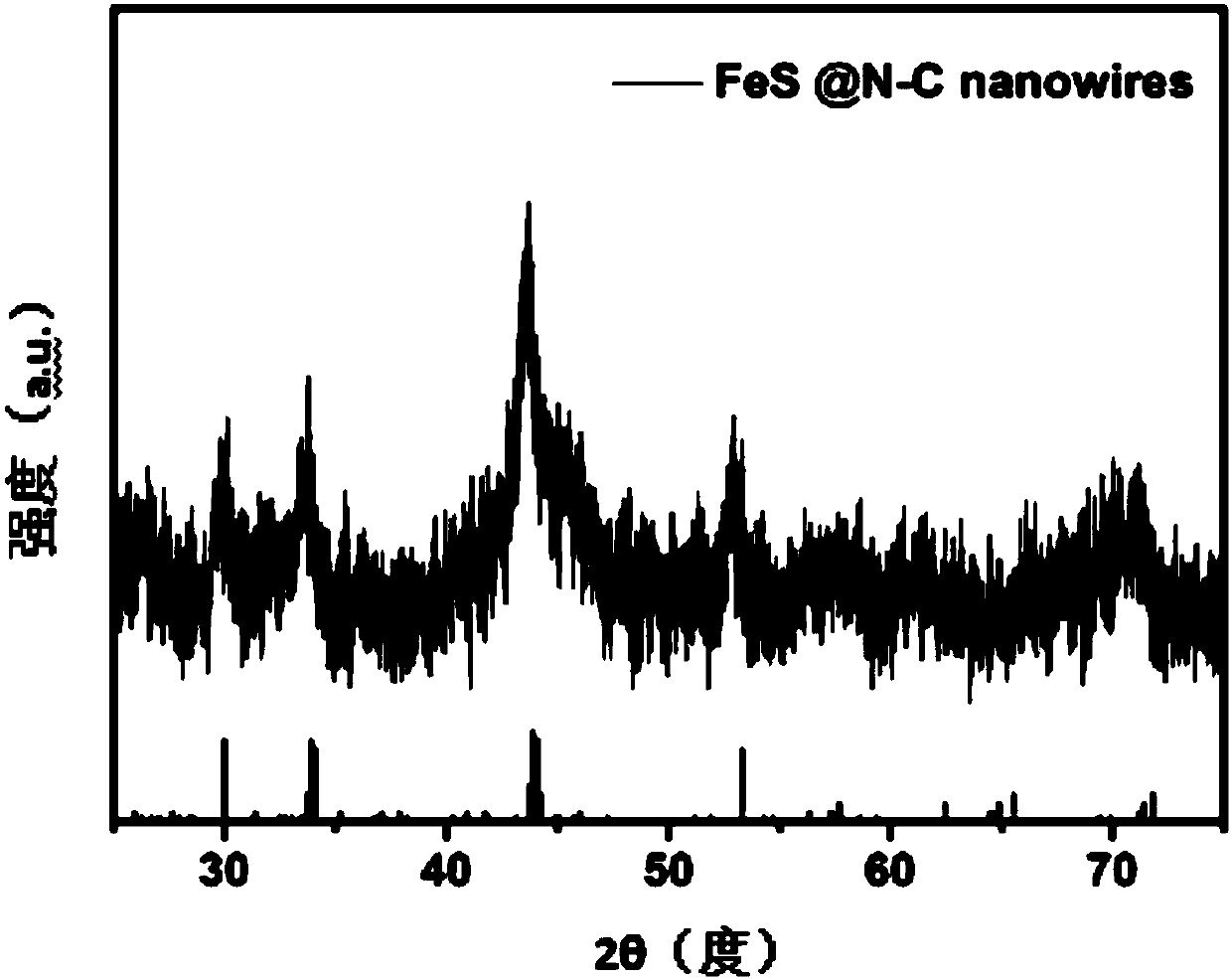

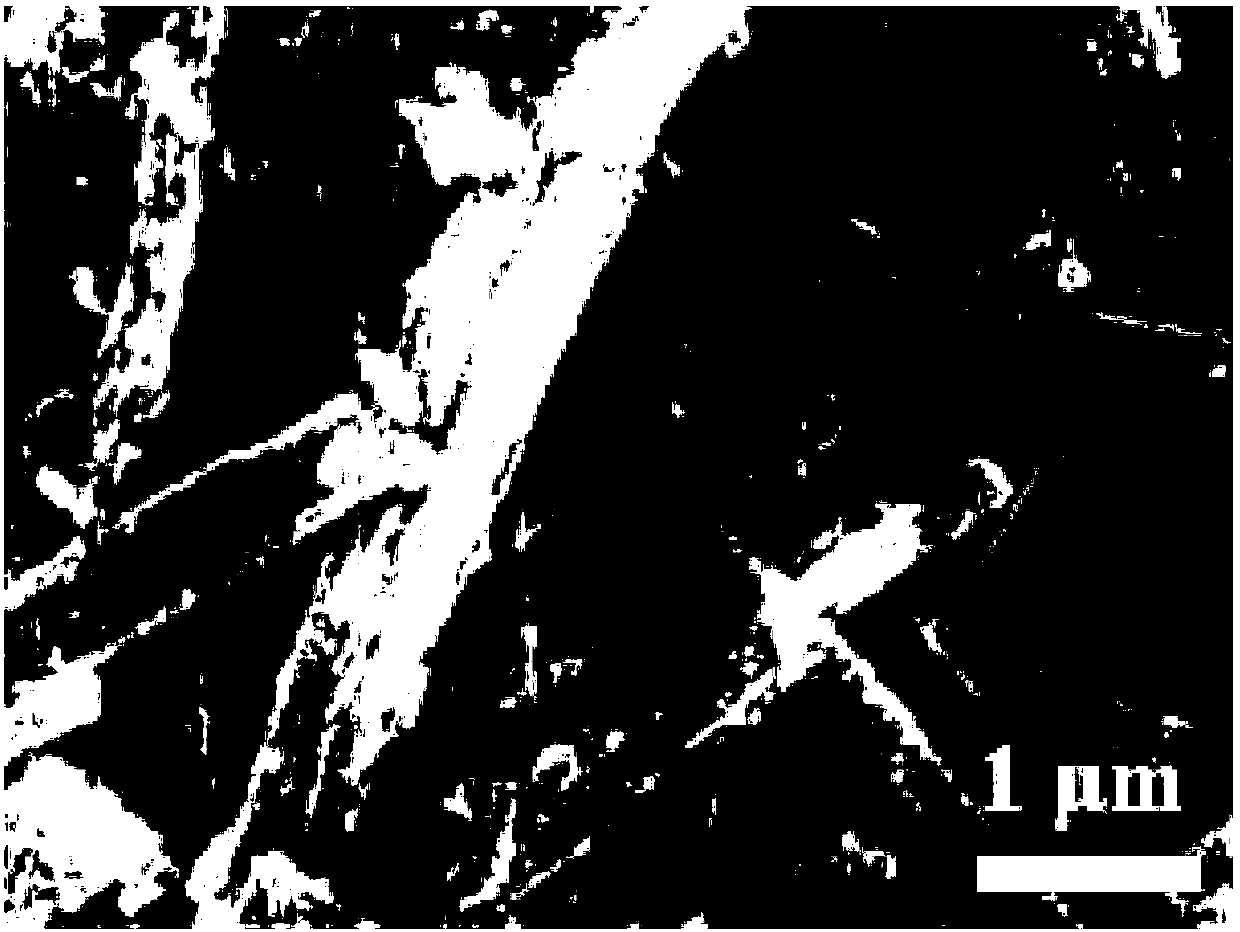

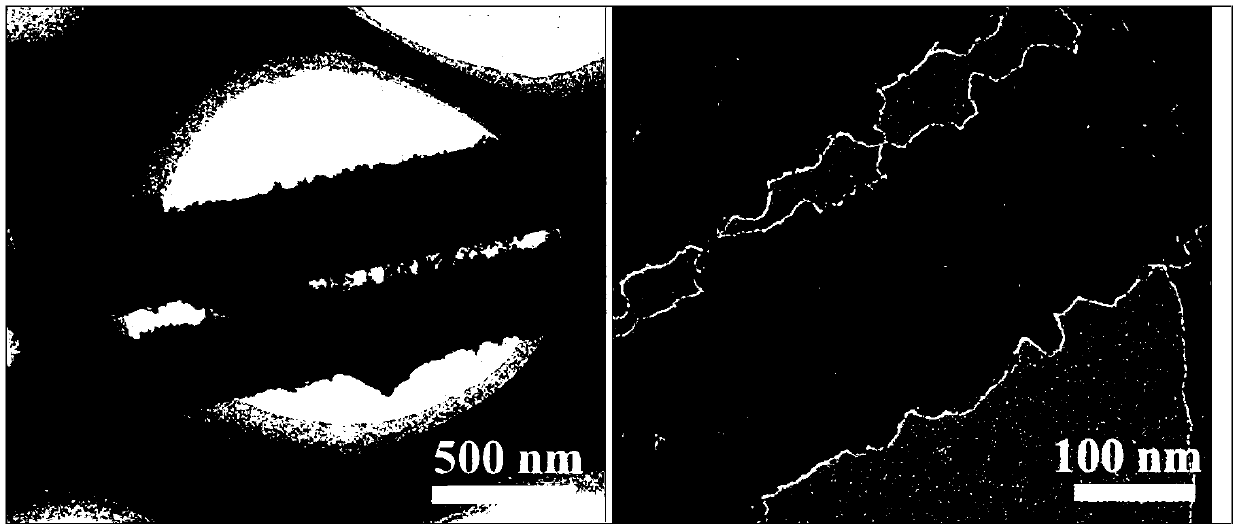

Porous ferrous sulfide nanowires and nitrogen doped carbon composite material and preparation method and application thereof

ActiveCN107634193AHigh yieldGood dispersionMaterial nanotechnologyCell electrodesCarbon compositesNanowire

The invention relates to porous ferrous sulfide nanowires and nitrogen doped carbon composite material and a preparation method thereof; the material can be used as a long-life and high-rate lithium ion battery negative electrode active material, is nanowires formed by compositing an in-situ generated ferrous sulfide nano-crystalline grains and nitrogen doped carbon, has a porous structure, and has the length of 1-10 [mu]m, the width of 100-500 nm and the thickness of 8-15 nm. The composite material has the beneficial effects that the simple hydrothermal and calcining method is only adopted, and the prepared material has high yield and good dispersibility, and makes great efforts to explore large-scale synthesis of nano materials with excellent performance and high rate; the method is simple in process, meets the requirements of green chemistry, has low requirements for equipment and has great potential for application; and the method shortens the diffusion distance of lithium ions andelectrons, buffers the volume change during the cycle process, thereby effectively improving the electrochemical performance of the material.

Owner:WUHAN UNIV OF TECH

Method for producing synthetic gas by reforming by-product glycerin vapor of biological diesel production

InactiveCN100462299CEasy to makeEasy to operateHydrogenBulk chemical productionSteam reformingSyngas

The invention discloses a preparing method of synthetic gas through reforming the by-product glycerin steam of biological diesel in the preparing technology of synthetic gas, which comprises the following steps: filling Ni / ZrO2 or Ni / CeO2 or Ni / CeO2-ZrO2 activator into reactor; setting the content of nickel at 10%-15%; adopting hydrogen gas and nitrogen gaseous mixture; proceeding reducing pre-treatment for the activator; leading glycerin water solution steam into the reactor with air speed at 5000-20000h-1 and ratio of water and carbon at 1:1-5:1; steam-reforming under normal pressure and with temperature at 300-600 deg. c; preparing the product. This invention possesses the advantages of simple craft course, low cost and wide prospect, which is fit for the requirement of green chemistry.

Owner:TIANJIN UNIV

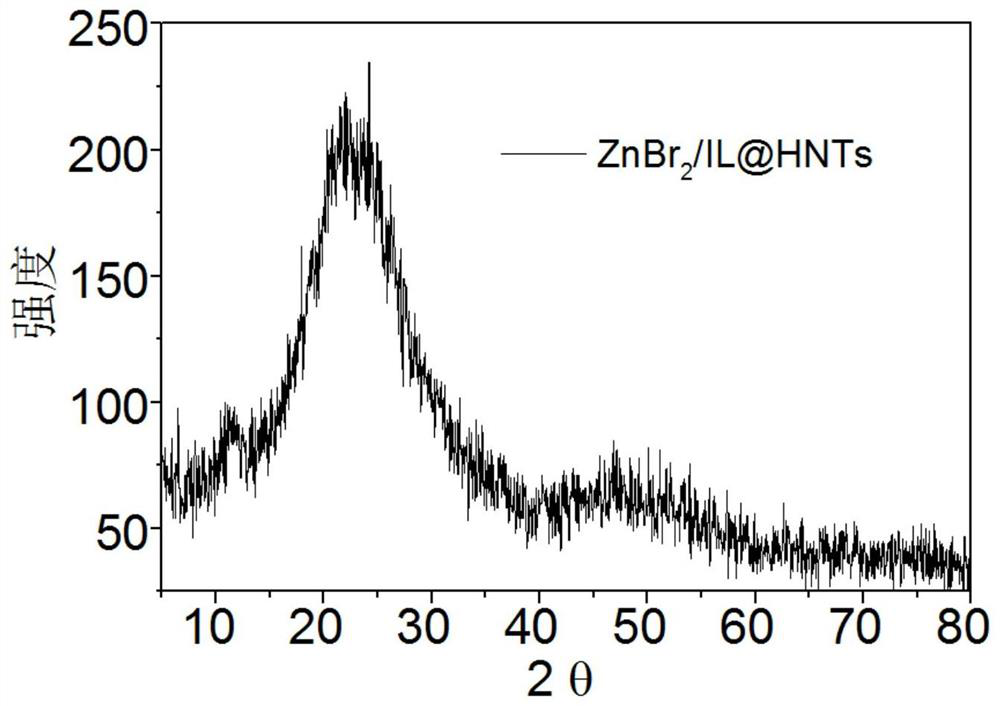

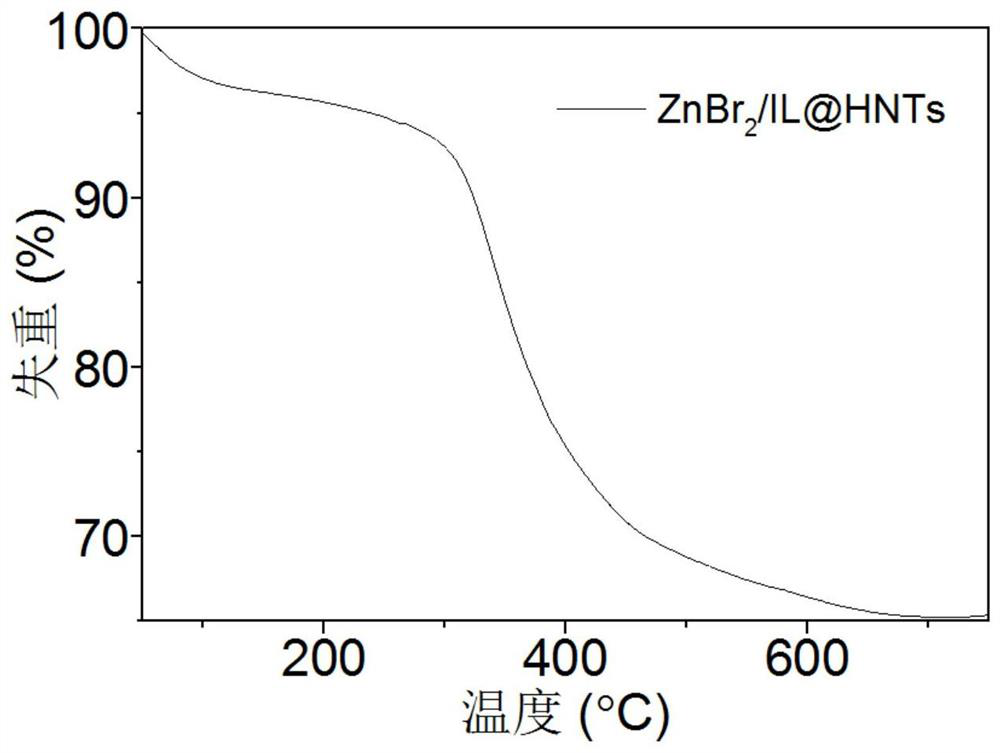

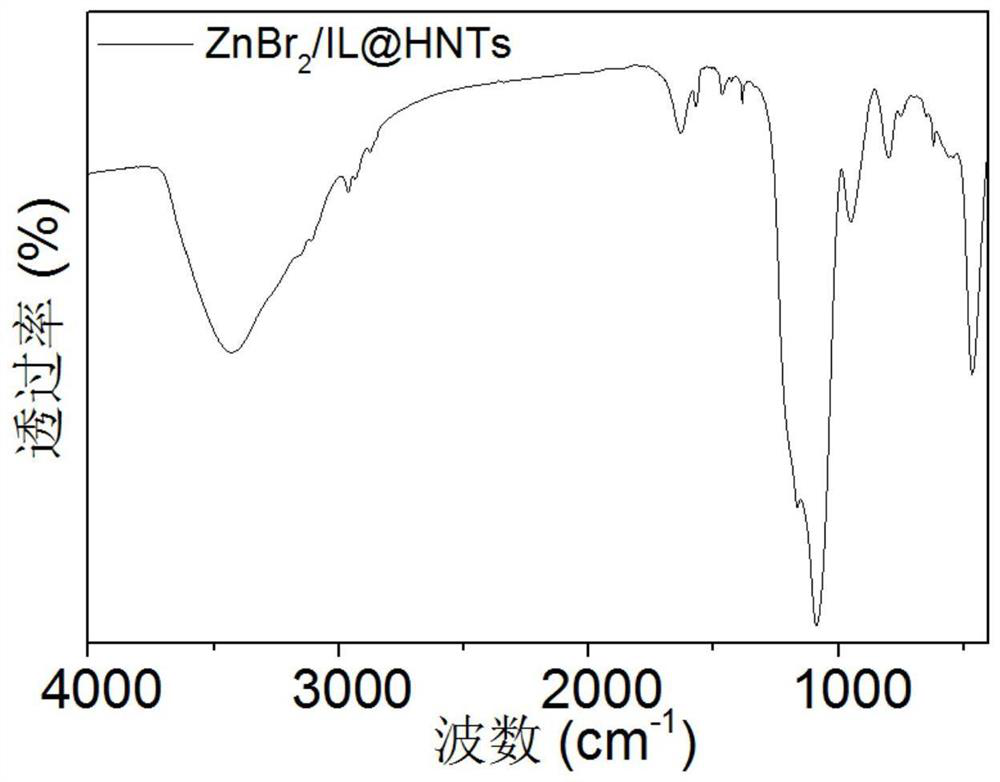

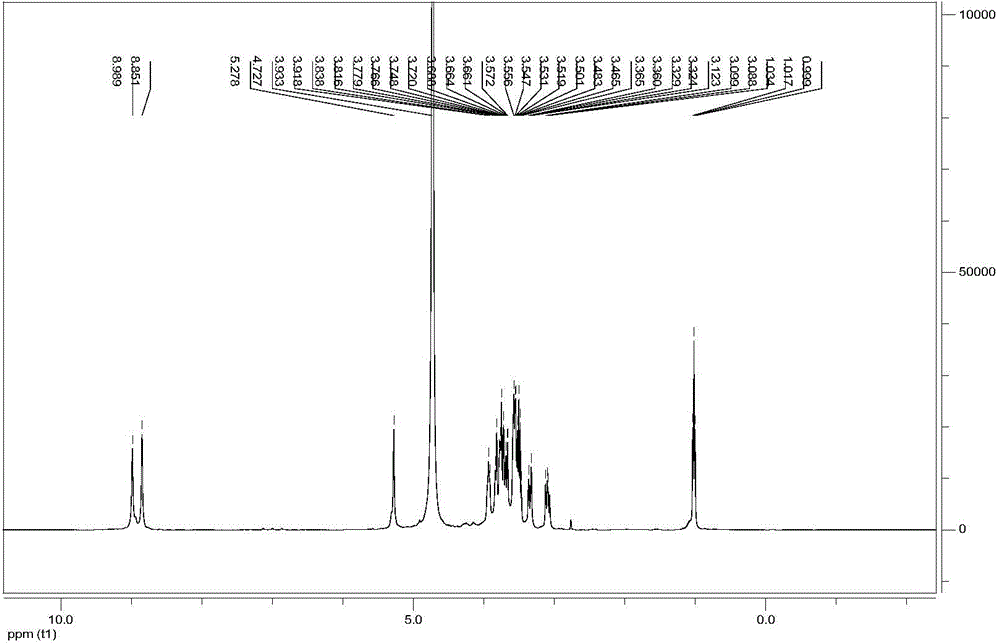

Interfacial ionic liquid supported catalyst for synthesizing cyclic carbonate from carbon dioxide

InactiveCN113117747ALow costThe synthesis steps are simpleOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystCarbonate ester

The invention discloses an interfacial ionic liquid supported catalyst for synthesizing cyclic carbonate from carbon dioxide. The catalyst is characterized in that the carrier is a mineral material and has the characteristics of low price, large specific surface area, porous structure and the like, and the ionic liquid is loaded on the carrier, so that the catalytic performance of the ionic liquid is improved, the dosage of the ionic liquid is greatly reduced, the cost is saved, and the catalyst can be used as a heterogeneous catalyst and is beneficial to recovery and recycling of the catalyst. The catalyst is prepared by mechanically stirring and synthesizing an ionic liquid, zinc halide and a mineral material in a nitrogen atmosphere, compounding various reactants according to a certain feeding ratio, and stirring and reacting at the temperature of 80-140 DEG C for 10-14 hours. The catalyst is low in price and easy to prepare, has excellent catalytic activity and selectivity for catalyzing epoxide and carbon dioxide to generate cyclic carbonate, and is a novel catalyst capable of being produced on a large scale.

Owner:JILIN UNIV

Method for preparing nitrogen-containing heterocyclic ring compound by use of chitin biomass

ActiveCN103951622AWide variety of sourcesRich reservesOrganic chemistryWater bathsNitrogenous heterocyclic compound

The invention discloses a method for preparing a nitrogen-containing heterocyclic ring compound by use of chitin biomass. The method comprises the following steps: uniformly mixing a chitin biomass raw material, an imidazole type ionic liquid solution and an additive for reaction, sequentially adding acetic oxide and pyridine into a reaction product for acylation, quenching the acylation-finished reaction liquid, adding an extracting agent into the acylation-finished reaction liquid for extraction, rotationally evaporating and concentrating to obtain an acylation product, adding an NaOH solution into the acylation product which is obtained through the extraction, stirring under a water-bath condition, adding hydrochloric acid which has the same molar weight as alkali, adding methanol, filtering to remove inorganic salt, rotationally evaporating and concentrating the filtrate to obtain a deacylation product, and crystallizing the deacylation product. The method disclosed by the invention has the advantages of simple process, high product purity, high yield and short reaction time.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

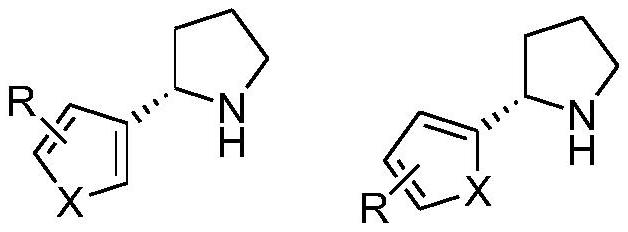

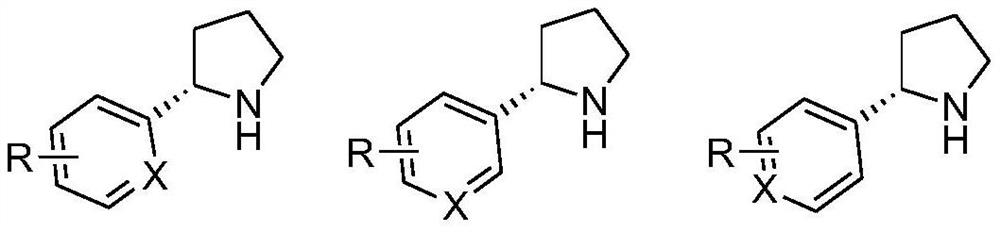

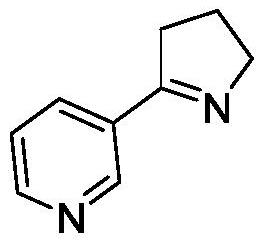

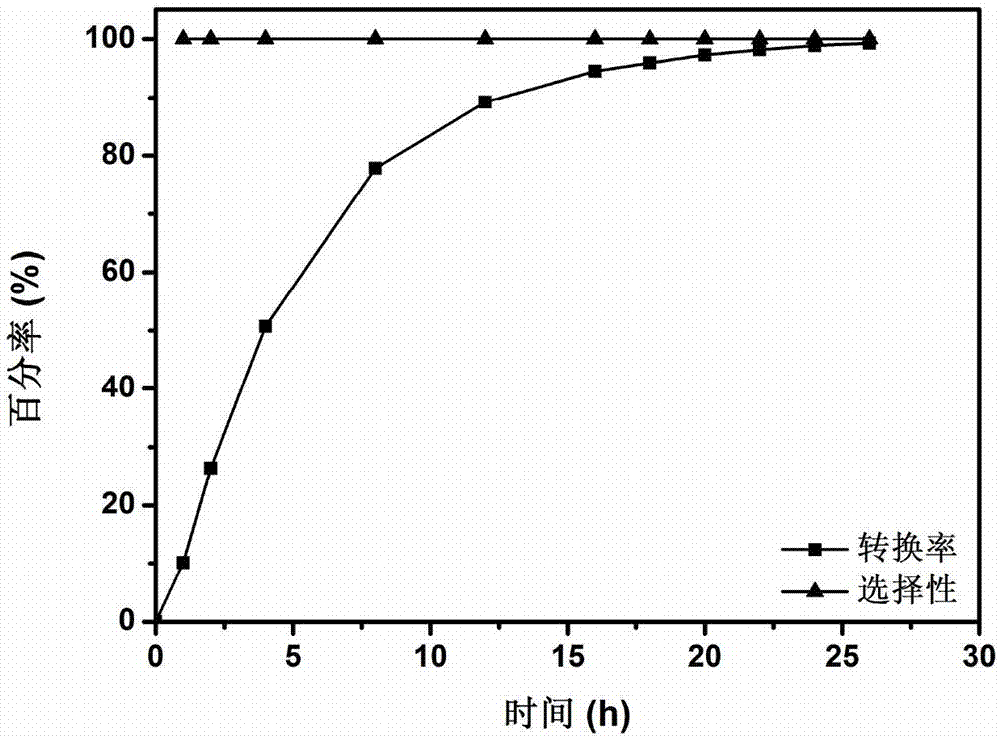

Method for preparing (S)-2-(3-pyridine)-pyrrolidine

The invention provides a method for preparing (S)-2-(3-pyridine)-pyrrolidine. The chiral 2-pyridine pyrrolidine compound is prepared by utilizing imine reductase (IRED) or engineering bacteria for expressing the imine reductase (IRED). A glucose dehydrogenase / glucose system is utilized to realize regeneration of coenzyme. More specifically, the invention provides a method for reducing a 2-pyridine-1-pyrroline compound into (S)-2-(3-pyridine)-pyrrolidine by utilizing the imine reductase derived from Myxococcus fulvus and a genetically engineered bacterium thereof, the imine reductase derived from Myxococcus fulvus is relatively high in activity, relatively high in reaction substrate concentration, relatively high in reaction yield and relatively high in optical purity of a product, In the reaction process, operation is easy, energy consumption is low, the green chemical requirement is met, and the method can be applied to biotransformation preparation of the (S)-2-(3-pyridine)-pyrrolidine compound in industrial production.

Owner:SHANDONG JINCHENG PHARMACCUTICAL CHEM CO LTD +1

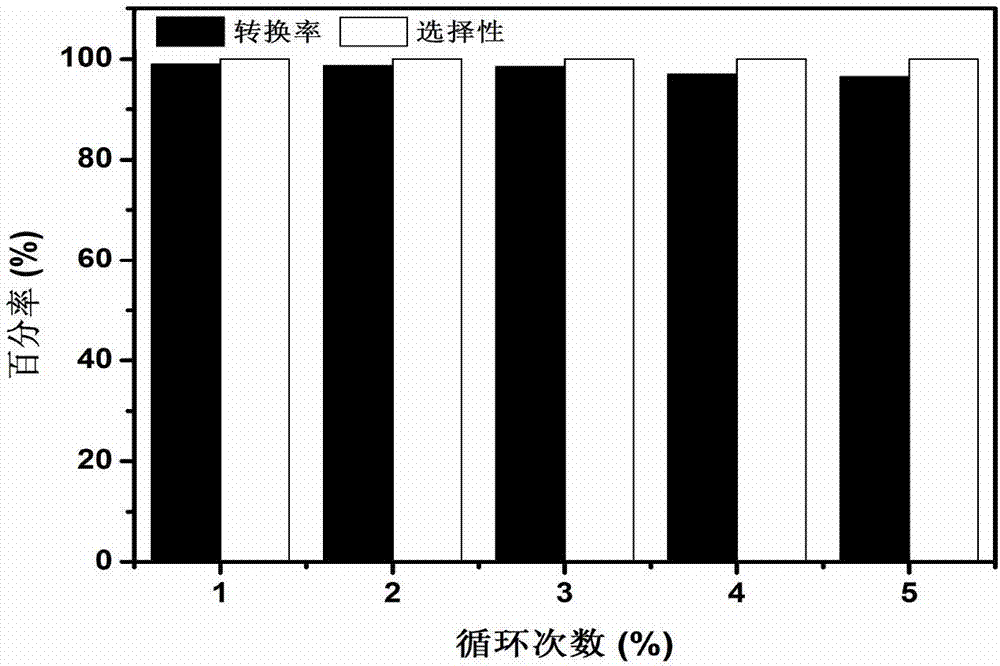

Preparation and application of loaded Pd3Cl cluster catalyst

ActiveCN107335454ACompliant with Green Chemistry RequirementsReduce loadPhysical/chemical process catalystsOrganic compound preparationKetoneOxygen

The invention discloses a preparation and application of a loaded Pd3Cl cluster catalyst. The molecular formula of a Pd3Cl cluster is: [Pd3Cl(PPh2)2(PPh3)3]<+>, and the catalyst is recorded briefly as Pd3Cl@TNT. The loaded Pd3Cl cluster catalyst is prepared by loading the Pd3Cl cluster on a TNT (Trinitrotoluol) carrier. The catalyst Pd3Cl@TNT disclosed by the invention is capable of catalyzing primary (secondary) alcohol oxidation with high activity under an oxygen (normal pressure) condition, and corresponding aldehyde (ketone) can be correspondingly prepared with high selectivity. Reaction conditions are gentle, no catalyst or additive is needed, a small amount of the catalyst is used, a substrate application range is relatively wide, and meanwhile the catalyst can be recycled and reused for more than five times and has very good practicability.

Owner:ANHUI UNIVERSITY

Method for production of 5-hydroxymethylfurfural or levulinic acid from inulin biomass

ActiveCN104130223ALow reaction temperatureFast responseOrganic compound preparationCarboxylic compound preparationInulinAqueous solution

The invention relates to a method for production of 5-hydroxymethylfurfural (5-HMF) or levulinic acid from an inulin biomass. The method includes: mixing a dry inulin biomass raw material, a zinc chloride aqueous solution and a catalyst evenly; or mixing the dry inulin biomass raw material with the zinc chloride aqueous solution uniformly, letting them react for 10min-8h at 60-140DEG C, then performing cooling to room temperature, conducting extraction on the reaction mixture by an organic extraction agent to extract 5-HMF or levulinic acid from the reaction system, then concentrating and drying the extraction agent, and conducting crystallization, thus obtaining the 5-HMF or levulinic acid product. The method provided by the invention has the advantages of accurate control of the product as 5-HMF or levulinic acid.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

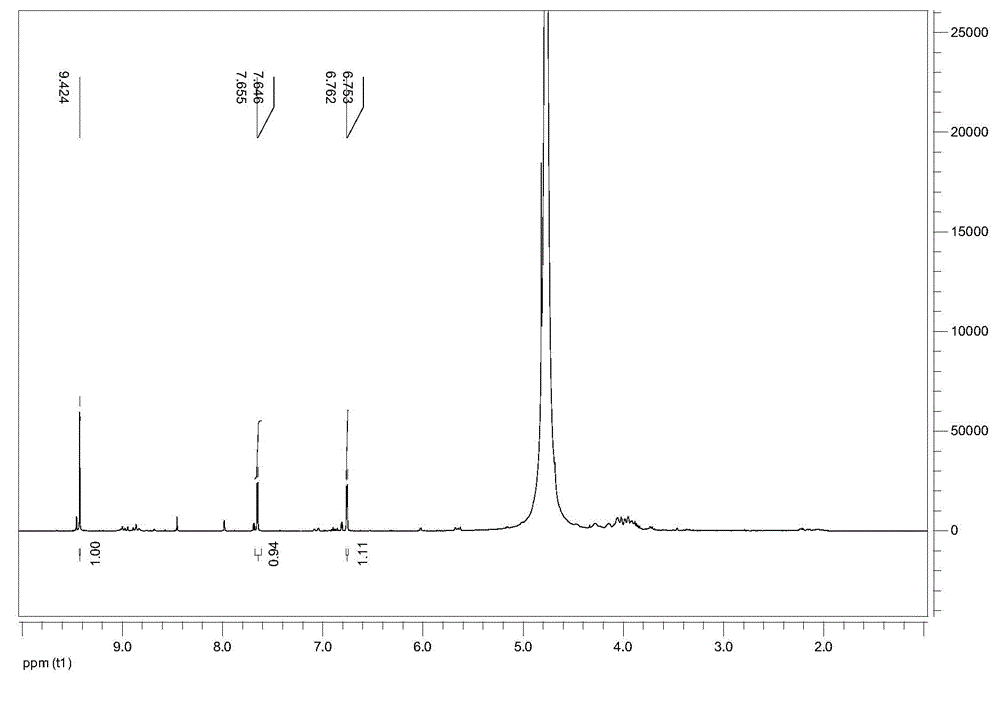

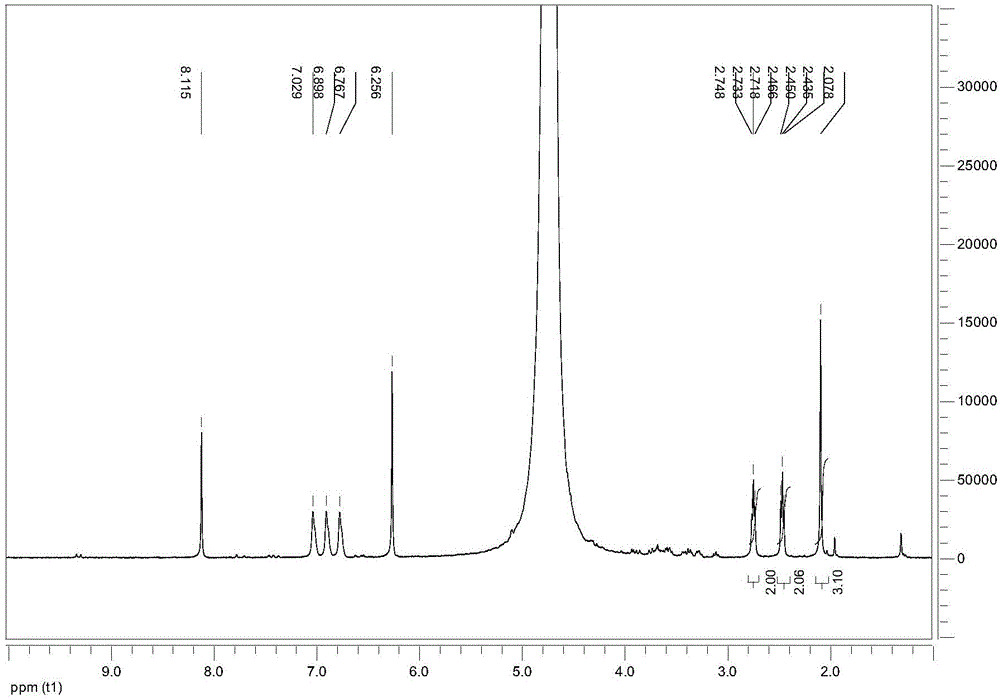

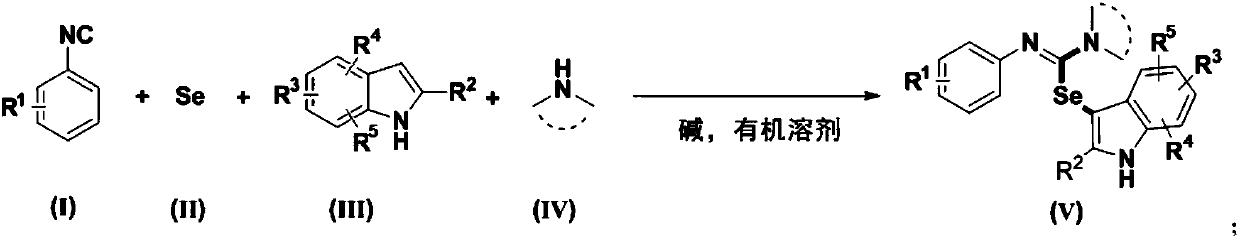

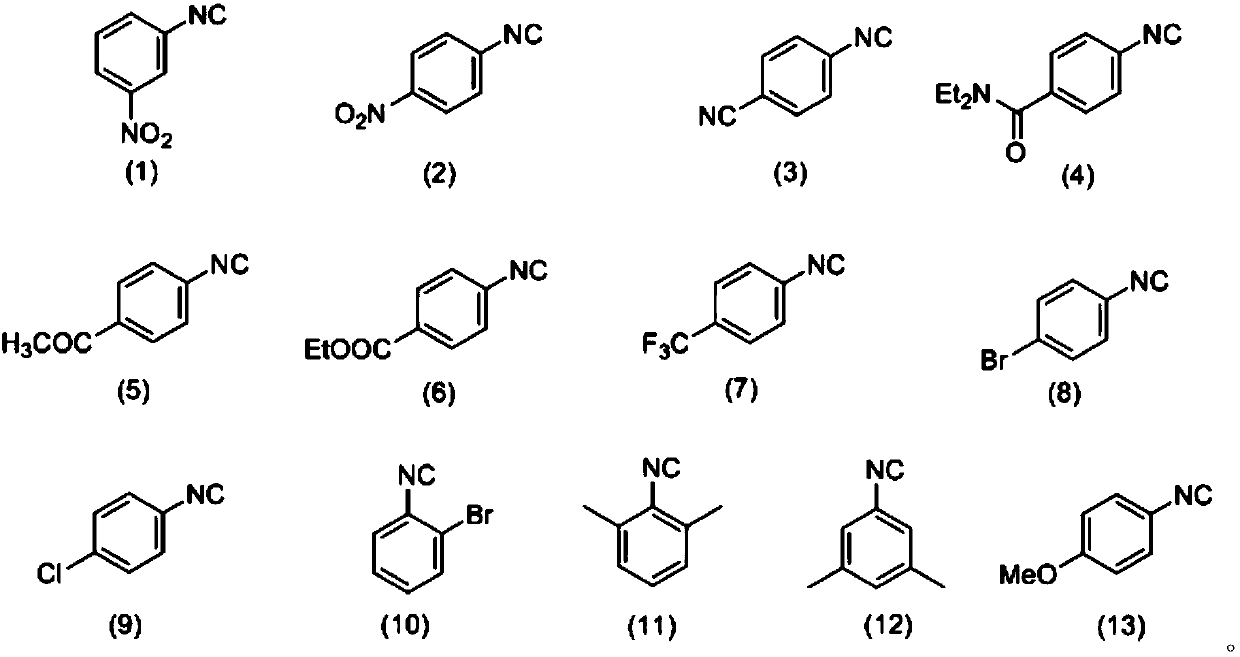

A synthetic method of 3-seleno indoles

ActiveCN107778210AEasy to operateRaw materials are cheap and easy to getOrganic chemistryAir atmosphereTrifluoromethyl

The invention relates to a synthetic method of 3-seleno indoles. An isonitrile compound shown as a formula (I), elemental selenium shown as a formula (II), an indole compound shown as a formula (III)and a secondary amine shown as a formula (IV) are reacted at 25-70 DEG C under functions of an alkali in an air atmosphere by adopting an organic solvent as a reaction medium to obtain one of the 3-seleno indoles shown as a formula (V). The reaction route is shown in the specification, wherein R1 is selected from nitro, cyano, acetyl, acylamino, alkyl, alkoxy, an ester group, trifluoromethyl or halogen, R2 is selected from hydrogen, phenyl, substituted phenyl or alkyl, and R3, R4 and R5 are independently selected from hydrogen, phenyl, alkyl, cyano, nitro, an ester group, alkoxy or halogen. The secondary amine shown as the formula (IV) is selected from noncyclic aliphatic secondary amines, cyclic aliphatic secondary amines or aromatic secondary amines. Reaction conditions of the method aremild and the method is environmentally-friendly.

Owner:SUZHOU UNIV

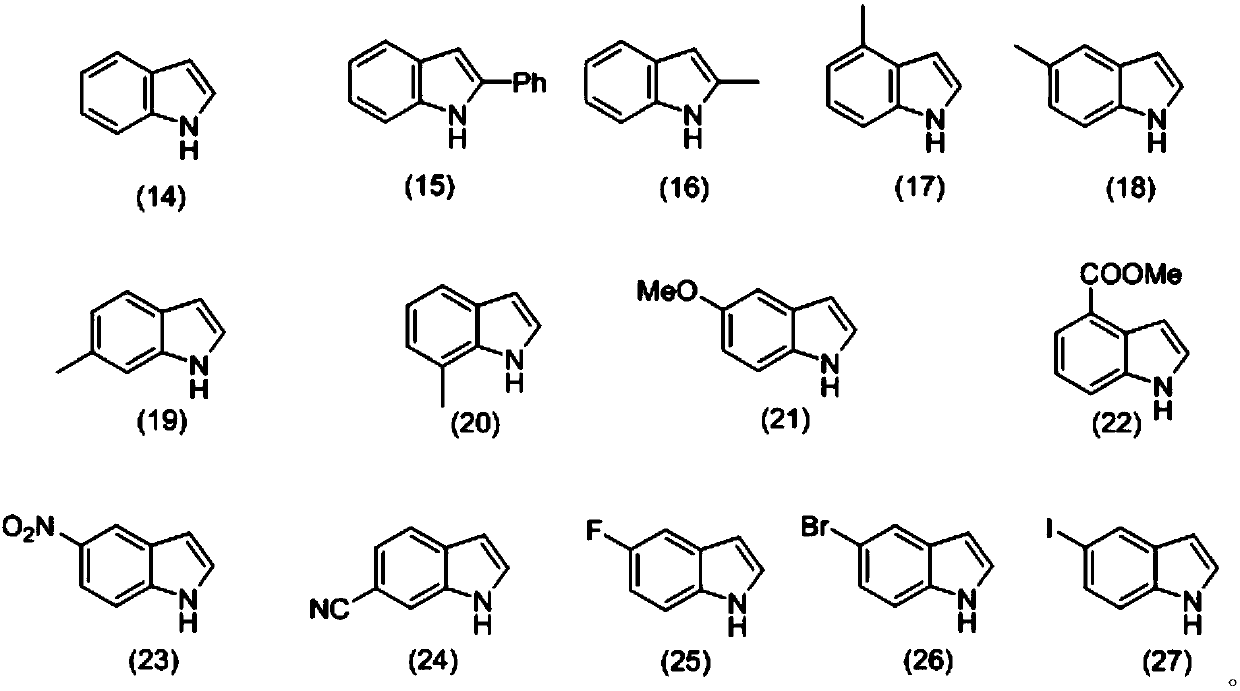

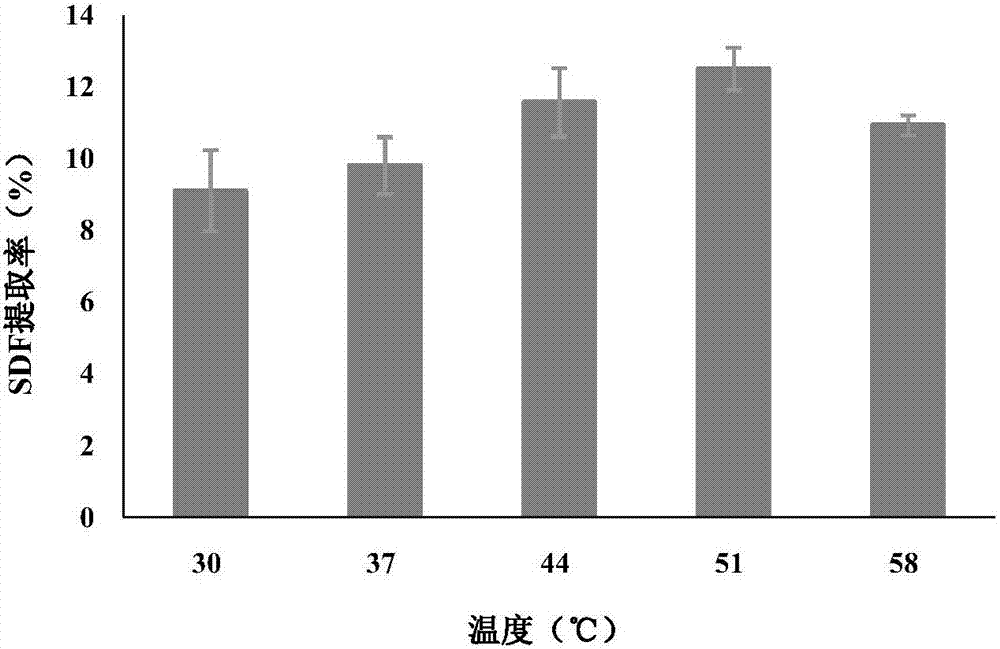

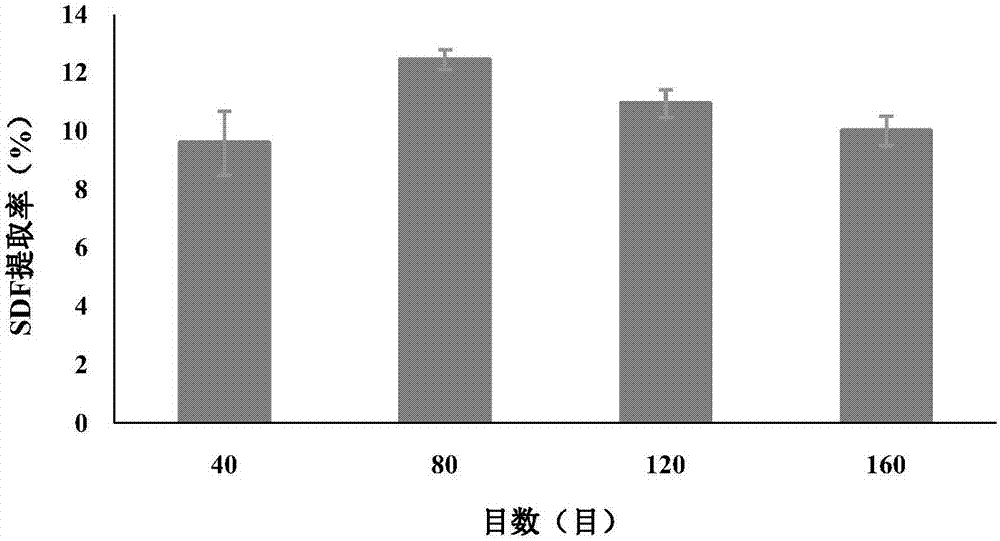

Method for extracting water-soluble dietary fibers from lentinus edodes stems

The invention discloses a method for extracting water-soluble dietary fibers from lentinus edodes stems. The method includes the following steps that 1, the lentinus edodes stem raw materials are dried, smashed and then sieved, and uniform lentinus edodes stem powder is obtained; 2, a buffer solution is added into the lentinus edodes stem powder, a cellulase solution is added, the materials are stirred to be uniform for enzymatic hydrolysis, enzyme deactivation is carried out after enzymolysis is completed, and reaction liquid is obtained; 3, the reaction liquid is centrifuged for solid-liquid separation, supernatant liquid is taken for concentration, and concentrated liquid is obtained; 4, absolute ethyl alcohol is added into the concentrated liquid, after the materials are fully mixed, the mixture stands overnight, suction filtration is carried out, sediment products are obtained and dried to constant weight, and the water-soluble dietary fibers are obtained. The factors, affecting the extraction rate of the water-soluble dietary fibers, of the enzymolysis temperature, use amount, mesh number and enzymolysis time of cellulase are optimized, so that the extraction rate of the water-soluble dietary fibers is increased, and the extracted water-soluble dietary fibers have high water-holding power.

Owner:HEBEI AGRICULTURAL UNIV.

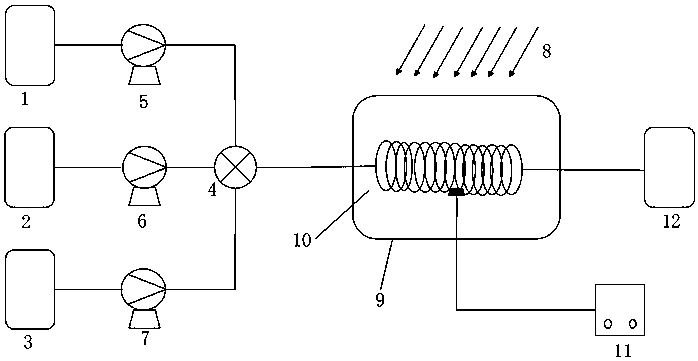

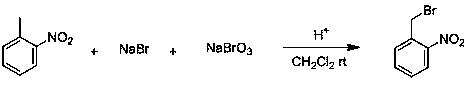

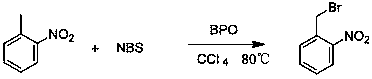

Device for continuous preparation of o-nitrobenzyl bromide and preparation method thereof

InactiveCN109999747AShort reaction timeReduce backmixingOrganic compound preparationOrganic chemistry methodsMeasuring instrumentOrganic layer

The invention relates to a device for continuous preparation of o-nitrobenzyl bromide and a preparation method thereof. The device mainly comprises a tubular reactor, three storage tanks, three corresponding metering pumps, an efficient mixer and a receiving tank. The storage tanks are connected to the efficient mixer through pipelines. The metering pumps are distributed on the connecting pipelines of the corresponding storage tanks and the efficient mixer. The efficient mixer is successively connected to the tubular reactor and the receiving tank. A light source is arranged above the tubularreactor. A temperature measuring instrument is arranged in the tubular reactor. The preparation method comprises the following steps: raw materials including ortho-nitrotoluene, liquid bromine and water enter the mixer respectively through the three metering pumps to be uniformly mixed; the mixture then enters a pre-insulated tubular reactor to react under illumination; the reaction product entersthe receiving tank after the reaction, followed by standing; and an organic layer is taken, and an organic solvent is removed to obtain the product. The preparation method of o-nitrobenzyl bromide isconvenient to operate; the post-treatment is simple; the product has good yield and high purity, and is suitable for industrial production.

Owner:ZHEJIANG UNIV OF TECH

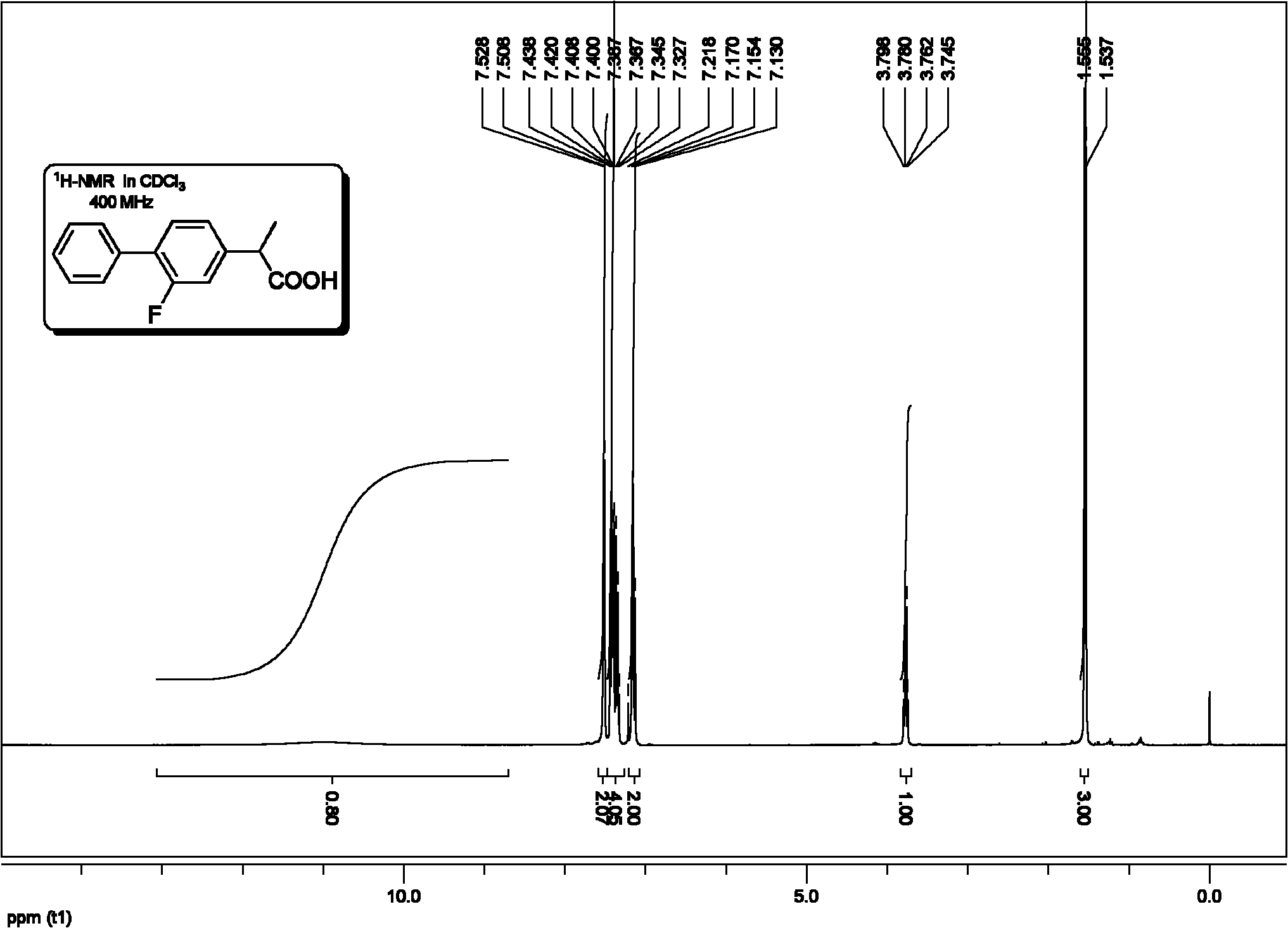

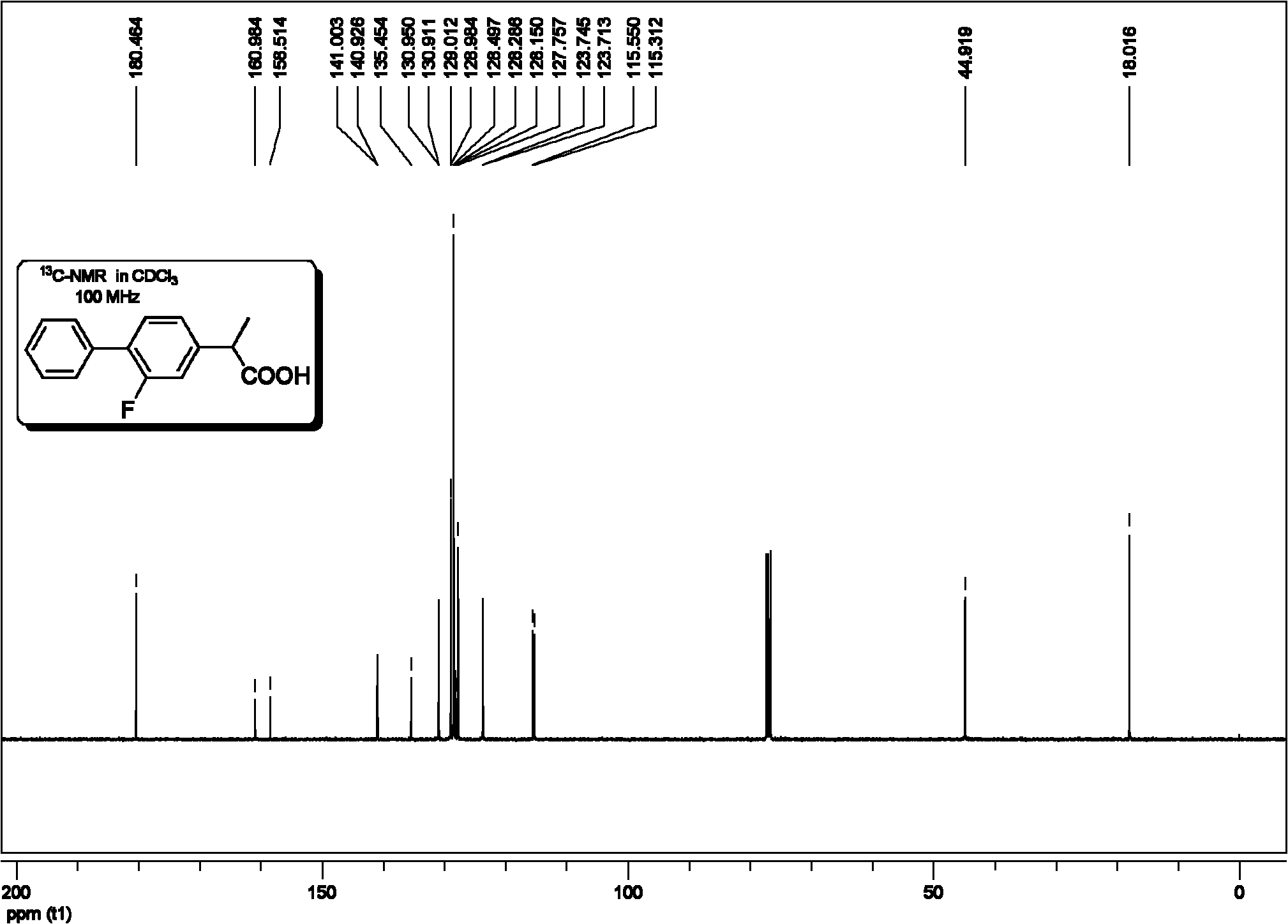

Method for synthesis of flurbiprofen

InactiveCN101973869AWide variety of sourcesLow costPreparation from nitrilesInorganic saltsCyanoacetic acid

The invention provides a method for the synthesis of flurbiprofen, which comprises the step that: 4-halo-2-fluorobiphenyl and cyanoacetic acid salt derivative are dissolved in solvent to be subjected to decarboxylation coupled reaction, methylation and hydrolysis under the action of palladium catalyst and organophosphorus ligand, in order to synthesize the target product within three steps; the method has the advantages of great simplicity and convenience, easy operation, wide source of raw materials, low cost, only the generation of inorganic salt and carbon dioxide in the synthesis process,good safety, environmental protection, consistency with the requirement of green chemistry and superior suitability for industrial production.

Owner:UNIV OF SCI & TECH OF CHINA

Preparation method of cyclohexene oxide

InactiveCN102786500AImprove oxygen storage capacityGood catalytic epoxidation effectOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsCyclohexene oxideOxygen

A preparation method of cyclohexene oxide belongs to the technical field of preparation of fine chemicals. The preparation method includes using cyclohexene as substrate, using acetonitrile as reaction solvent, using 30wt% hydrogen peroxide as oxidant, using Ti-MCM-41 molecular sieve to carry phosphomolybdic manganese heteropolyacid sodium salt for alkene epoxidation reaction, rectifying reaction liquid after reaction, selecting fraction at 130-135 DEG C so as to obtain cyclohexene oxide. The catalyst Ti-MCM-41 is used as a carrier to carry the composite oxide, the cyclohexene oxide is obtained by catalytic synthesis, catalytic activity is high, and the catalyst is reusable. The hydrogen peroxide is used as an oxygen source, byproduct is water, and the chemical requirement for environmental friendliness is met. The reaction starts under normal pressure under mild conditions, and reactant and the byproduct water are easy to separate. Reaction energy consumption is low, the requirement for reaction devices is low, and the preparation method is suitable for large-scale industrial production.

Owner:ZHEJIANG CENWAY MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com