Method for preparing carbon-based acid material by means of alkylated waste acid

A technology for alkylating waste acids and acidic materials, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of long preparation time, many preparation procedures, and low oxidation efficiency, and achieve Reduced energy consumption, reduced reaction steps, and wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

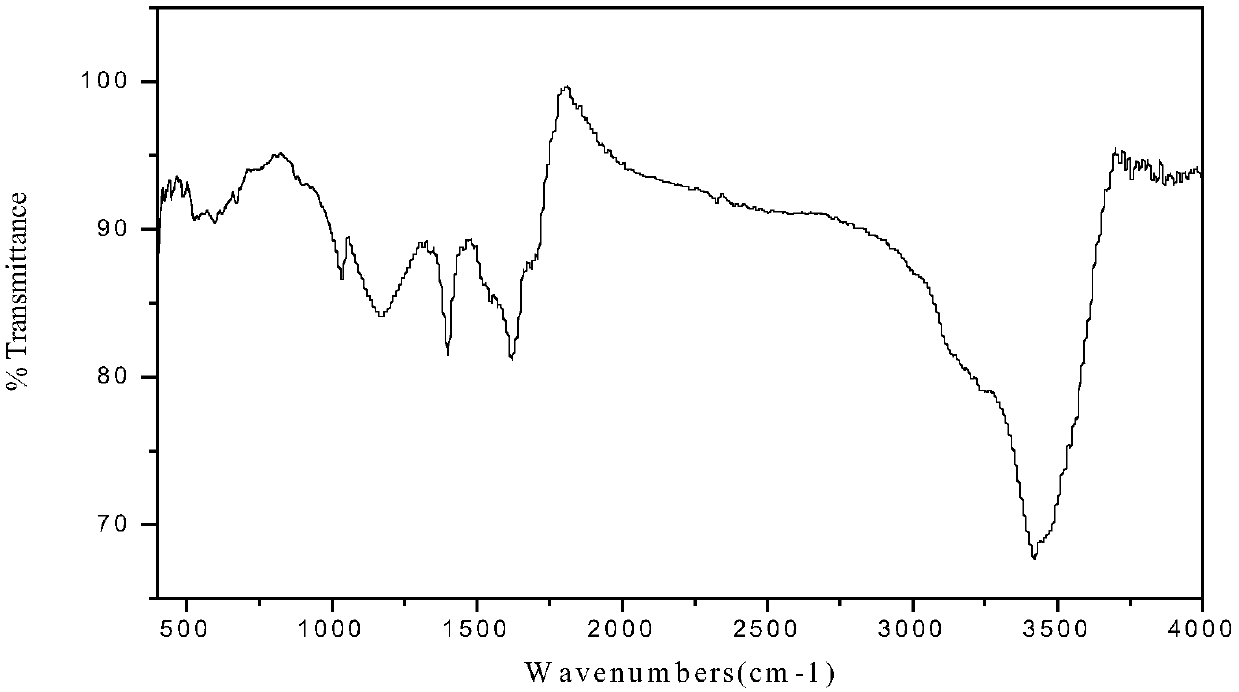

Image

Examples

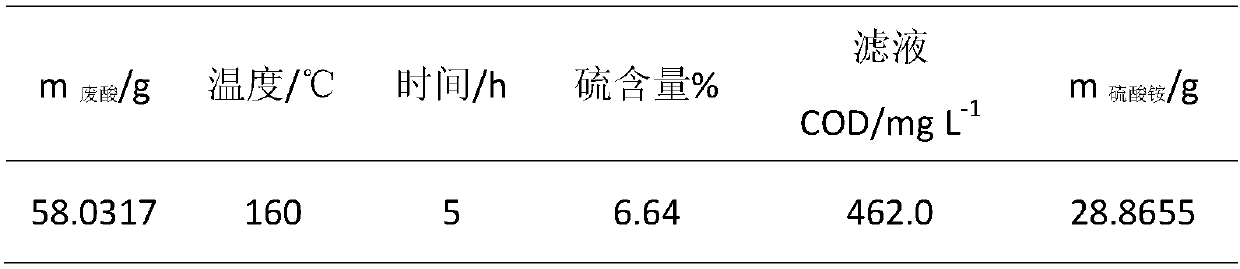

Embodiment example 1

[0026] Weigh a certain amount of waste acid in a round bottom flask (250ml), raise it from room temperature to 160°C, then maintain it for 5h, cool to room temperature, weigh 150% of the waste acid mass in water and add it to the round bottom flask. Stir overnight, filter with suction, obtain filtrate (dilute sulfuric acid solution) and filter cake (carbon-based acidic material), collect filtrate in the beaker, add ammoniacal liquor (25-28wt%) slowly under the condition of stirring, until the solution is neutral properties, and then the solution was evaporated, and crystals were precipitated. The filter cake was washed with deionized water until neutral, dried, and the sulfur content was detected by elemental analysis. Test the COD value of filtrate, the results are as shown in table 1:

[0027] Table 1

[0028]

Embodiment example 2

[0030] Weigh a certain amount of spent acid in a round-bottomed flask (250ml), raise it from room temperature to 180°C, then maintain it for 5h, cool to room temperature, weigh 200% of the spent acid mass in water and add it to the round-bottomed flask. Stir overnight, and filter with suction to obtain filtrate (dilute sulfuric acid solution) and filter cake (carbon-based acidic material), collect the filtrate into a beaker, rotate to obtain concentrated sulfuric acid, and titrate to measure the concentration of sulfuric acid. The filter cake was washed with deionized water until neutral, dried, and the sulfur content was detected by elemental analysis. Test the COD value of filtrate, the results are as shown in table 2:

[0031] Table 2

[0032]

Embodiment example 3

[0034] Take a certain amount of waste acid and carbon-based acidic material in a round bottom flask (250ml), raise it from room temperature to 160°C, then maintain it for 4h, cool to room temperature, weigh 100% water of the waste acid mass and add it to the round bottom flask Bottom flask, stirred overnight at room temperature, filtered with suction to obtain filtrate (dilute sulfuric acid solution) and filter cake (carbon-based acidic material). Collect the filtrate into a beaker, slowly add ammonia water (25-28wt%) under the condition of stirring until the solution is neutral, then evaporate the solution, and crystals are precipitated. The filter cake was washed with deionized water until neutral, dried, and the sulfur content was detected by elemental analysis. Test the COD value of filtrate, the results are as shown in table 3:

[0035] table 3

[0036]

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com