Preparation method of aminopyridine chloride

A technology of aminopyridine and chloride, which is applied in the field of preparation of aminopyridine chloride, can solve the problems of many by-products in the product, complex operation process, and low product yield, and achieve less by-products, high product purity, and post-treatment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

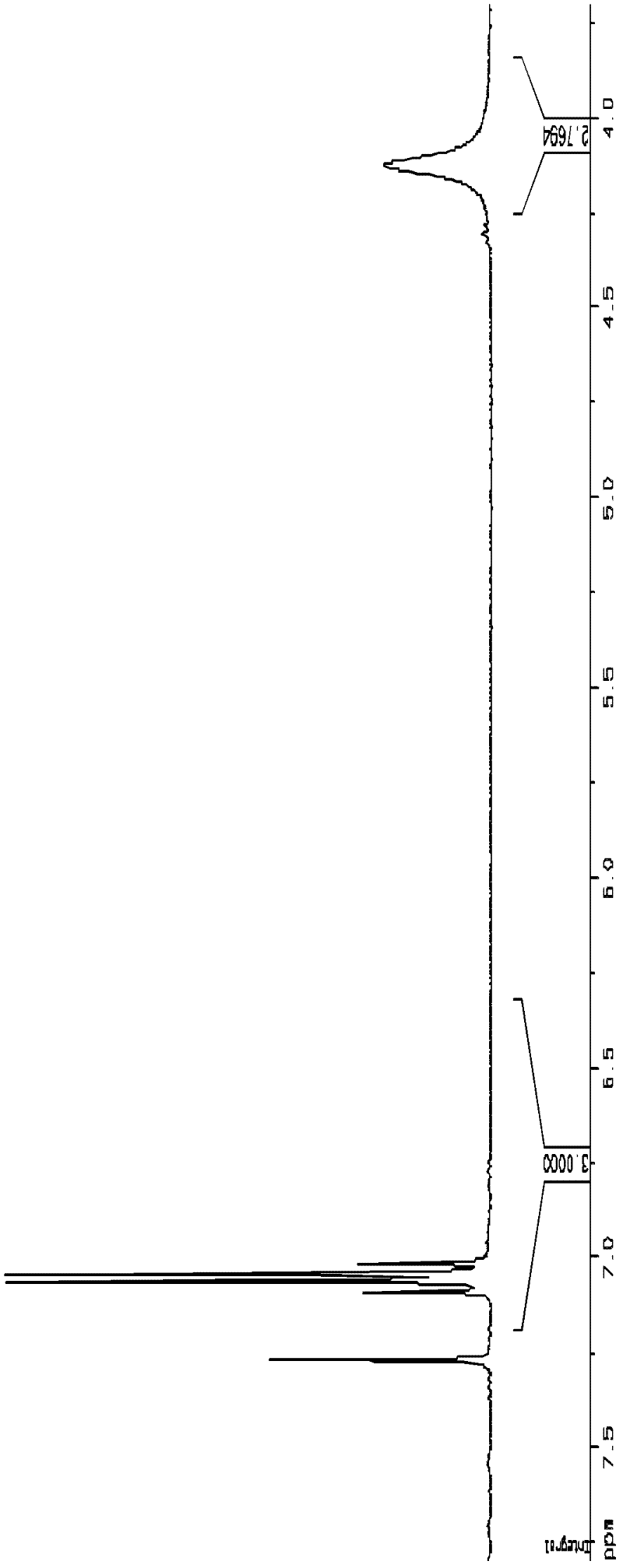

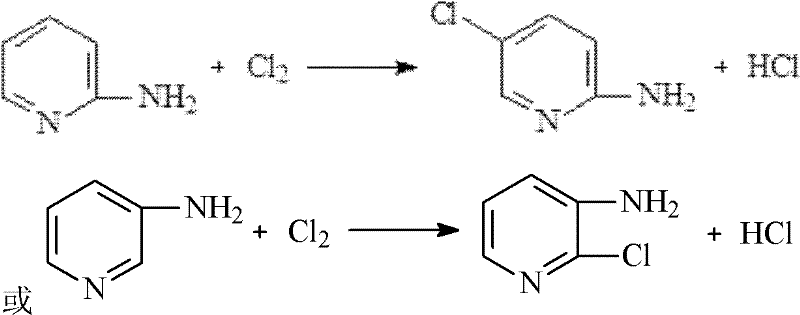

[0012] Specific embodiment one: the preparation method of a kind of aminopyridine chloride of this embodiment, specifically is finished according to the following steps:

[0013] 1. Electrolysis: Dissolve aminopyridine in the hydrochloric acid solution of the electrolytic cell without diaphragm to obtain the electrolytic solution of aminopyridine, then turn on the power supply, and at the same time pass nitrogen gas above the electrolytic cell without diaphragm to adjust the current intensity to 0.1A~0.4A , the voltage is 1.1V ~ 1.4V, electrolytic chlorination at room temperature for 2 ~ 12h, to obtain the reaction solution after electrolysis; 2. Separation and purification: add alkaline substances to the reaction solution after electrolysis in step 1 to adjust the pH value to 8 ~9, then use organic solvent extraction, separate the extraction phase, use the mass fraction of 15% ~ 35% sodium chloride solution to wash the extraction phase, until the pH value of the extraction pha...

specific Embodiment approach 2

[0025] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass fraction of HCl in the hydrochloric acid solution described in step 1 is 15-30%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass fraction of HCl in the hydrochloric acid solution described in step 1 is 20%. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com