Medium-low temperature solid-solid reaction method for preparing nano grade cerium-zirconium composite oxide solid solution

A composite oxide and nano-scale technology, applied in chemical instruments and methods, titanium oxide/hydroxide, rare earth metal compounds, etc., can solve problems such as long process flow, large specific surface area, and large product particle size, and achieve technological progress Simple, high specific surface area, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

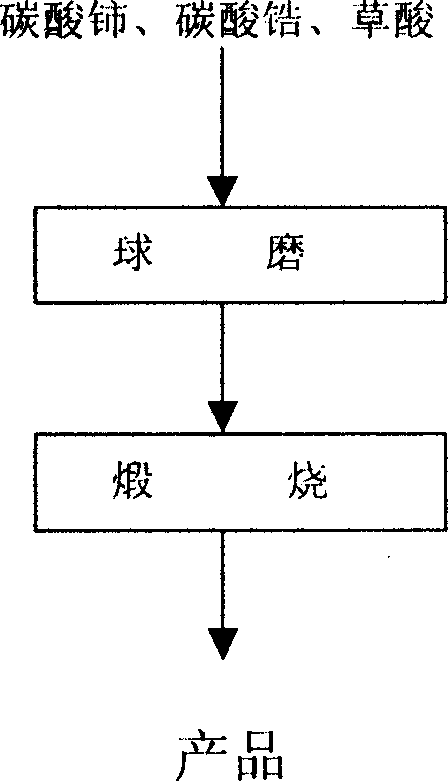

Method used

Image

Examples

specific example

[0028] 1. Weigh 10g of zirconium carbonate, 70.16g of cerium carbonate, and 88.80g of oxalic acid to mix them evenly, and put them into a ball mill for ball milling at a speed of 90 rpm for 60 minutes. The obtained precursor is calcined at a temperature of 300°C Calcined for 5 hours, the obtained product is nano-cerium-zirconium oxide with an average particle diameter of 30-40nm.

[0029] 2. Weigh 10g of zirconium carbonate, 23.40g of cerium carbonate, and 37.57g of oxalic acid to mix them evenly, and put them into a ball mill for ball milling at a speed of 90 rpm for 60 minutes. The obtained precursor is calcined at a temperature of 300°C After calcining for 3 hours, the obtained product is nano-cerium-zirconium oxide with an average particle diameter of 20-40nm.

[0030] 3. Weigh 10g of zirconium carbonate, 11.69g of cerium carbonate, and 24.75g of oxalic acid to mix them evenly, and put them into a ball mill for ball milling at a speed of 150 rpm for 45 minutes. The obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com