Preparation method of cyclohexene oxide

A technology of epoxy cyclohexane and cyclohexene is applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., and can solve the problems of unfavorable large-scale industrial application and complicated catalyst preparation process , the problem of high cost, to achieve the effect of shortening the residence time, reducing the generation of hydrolysis by-products, and low cost

Inactive Publication Date: 2012-11-21

ZHEJIANG CENWAY MATERIALS CO LTD

View PDF6 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the catalysts used have disadvantages such as complicated preparation process and high cost, which are not conducive to large-scale industrial application.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2~4

Embodiment example 5~8

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

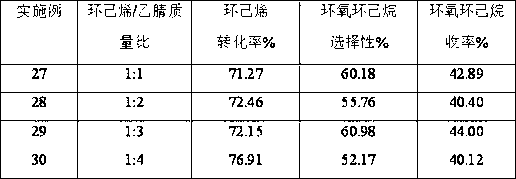

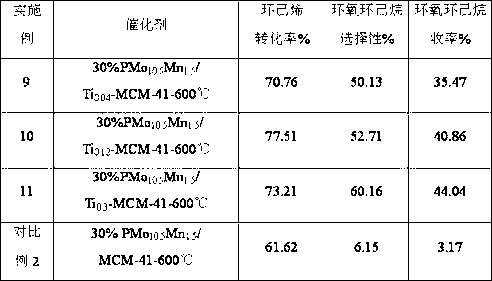

A preparation method of cyclohexene oxide belongs to the technical field of preparation of fine chemicals. The preparation method includes using cyclohexene as substrate, using acetonitrile as reaction solvent, using 30wt% hydrogen peroxide as oxidant, using Ti-MCM-41 molecular sieve to carry phosphomolybdic manganese heteropolyacid sodium salt for alkene epoxidation reaction, rectifying reaction liquid after reaction, selecting fraction at 130-135 DEG C so as to obtain cyclohexene oxide. The catalyst Ti-MCM-41 is used as a carrier to carry the composite oxide, the cyclohexene oxide is obtained by catalytic synthesis, catalytic activity is high, and the catalyst is reusable. The hydrogen peroxide is used as an oxygen source, byproduct is water, and the chemical requirement for environmental friendliness is met. The reaction starts under normal pressure under mild conditions, and reactant and the byproduct water are easy to separate. Reaction energy consumption is low, the requirement for reaction devices is low, and the preparation method is suitable for large-scale industrial production.

Description

technical field The invention belongs to the technical field of preparation of fine chemical products, and specifically relates to a method for preparing epoxycyclohexane by heterogeneous catalytic reaction with mild reaction conditions, simple catalyst preparation and easy separation from reaction solution, convenient product post-treatment, and less environmental pollution. Background technique There are active epoxy groups in the molecular structure of 1,2-epoxycyclohexane. Under the action of acid or alkali catalyst, the ternary oxygen-containing ring is very easy to ring-open, and it can react with ammonia, amine, alcohol, phenol, carboxylic acid, Water and other substances react to form a high value-added compound. Therefore, epoxycyclohexane is an important organic intermediate, and its industrial applications include the synthesis of epoxy resin active diluents and new pesticides such as dexamethasone. Most of the main methods for producing epoxycyclohexane in earl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07D303/04C07D301/12B01J31/38

Inventor 吴磊张波汤明慧

Owner ZHEJIANG CENWAY MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com