Iron-nitrogen-carbon composite material containing monatomic active sites as well as preparation and application methods of iron-nitrogen-carbon composite material

A composite material and active site technology, which is applied in the field of advanced oxidation, can solve the problems of poor activation effect of persulfate and increase the amount of slag at the end of water treatment, etc., and achieve less iron dissolution, low equipment requirements, and high yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] In order to obtain a substance capable of efficiently activating peroxymonosulfate, the present invention also provides a preparation method, which can be used to prepare the iron-nitrogen-carbon composite material as described in any of the above-mentioned embodiments, and the preparation method includes steps:

[0048] S1, dissolving a nitrogen-containing carbon source in an ethanol solution to obtain a solution A; wherein, the nitrogen-containing carbon source includes: one or more of melamine, dicyandiamide, and urea.

[0049] In addition, as another expanded option, the nitrogen-containing carbon source may also include: one or more of the melamine, the dicyandiamide, and the urea formed with glucose and / or sucrose The mixture, that is: the mixture formed after one or more of the melamine, the dicyandiamine, and the urea are selected and then mixed with glucose and / or sucrose can also be used as the present invention nitrogenous carbon source.

[0050] S2, dispers...

Embodiment 1

[0072] A method for preparing an iron-nitrogen-carbon composite material containing a single-atom active site, the specific steps are as follows:

[0073] 1. Weigh 10g of dicyandiamide and place it in 500ml of 75% alcohol solution, raise the temperature to 60°C, and ultrasonicate for 1 hour to prepare solution A.

[0074] 2. Weigh 200 mg of hemin and place it in solution A, and disperse it by ultrasonic for 3 hours; then evaporate at 60°C to complete dryness to obtain the mixed substance B.

[0075] 3. Grind the mixed substance B evenly, raise the temperature to 350°C at a heating rate of 3°C / min, keep at this temperature for 3 hours, continue to raise the temperature to 650°C at the same heating rate, and keep it for 5 hours. The temperature was lowered to room temperature, and then the cooled material was pickled, and finally the product was washed with deionized water to neutrality, and dried at 60°C to obtain an iron-nitrogen-carbon composite material containing a single-a...

Embodiment 2

[0087] According to the method of Example 1, the only difference is that the amount of hemin in step 2 is changed to 100mg.

[0088] The material obtained by the above method is denoted as Fe SA(100)-g-C 3 N 4 , which contains a graphite-like carbon nitride support and iron single atoms combined with the support.

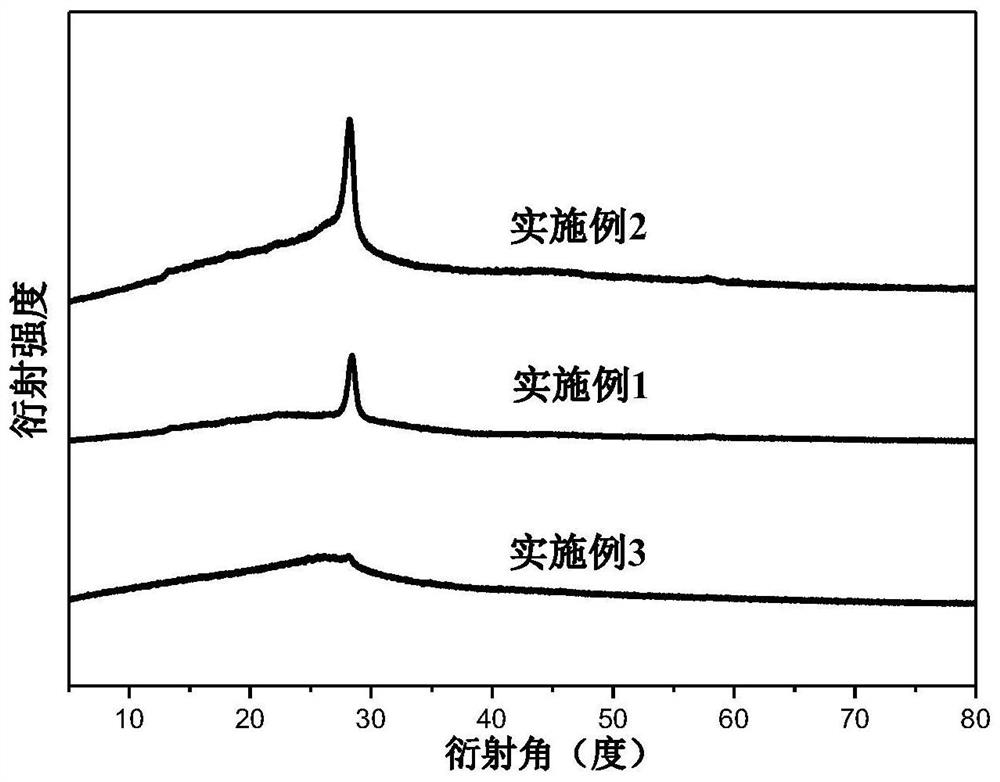

[0089] Such as figure 1 as shown, figure 1 Middle curve is Fe SA-g-C prepared in embodiment 1, embodiment 2, embodiment 3 3 N 4 powder diffraction (XRD) spectrum.

[0090] Depend on figure 1 It can be seen that the Fe SA(100)-g-C synthesized in Example 2 3 N 4 Only the peak of graphitic phase carbon nitride appears in the XRD spectrum of XRD, indicating that Fe is highly dispersed in it, and there is no Fe element or its compound nanoparticles, thereby forming and improving the activation of persulfate.

[0091] Furthermore, by the ICP-OES method, Fe SA(100)-g-C could be detected 3 N 4 In , the loading of Fe atoms is 1.32wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com