A method of preparing a hydrophobic type silicon dioxide aerogel material and a method of preparing a VIP vacuum plate and powder

A silica and aerogel technology, applied in the direction of silica, silica, chemical instruments and methods, etc., can solve the problems of cumbersome solvent replacement, colloid collapse, and inability to prepare high-performance materials, etc., and achieve simple preparation process , Improve production efficiency, improve production efficiency and the effect of added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

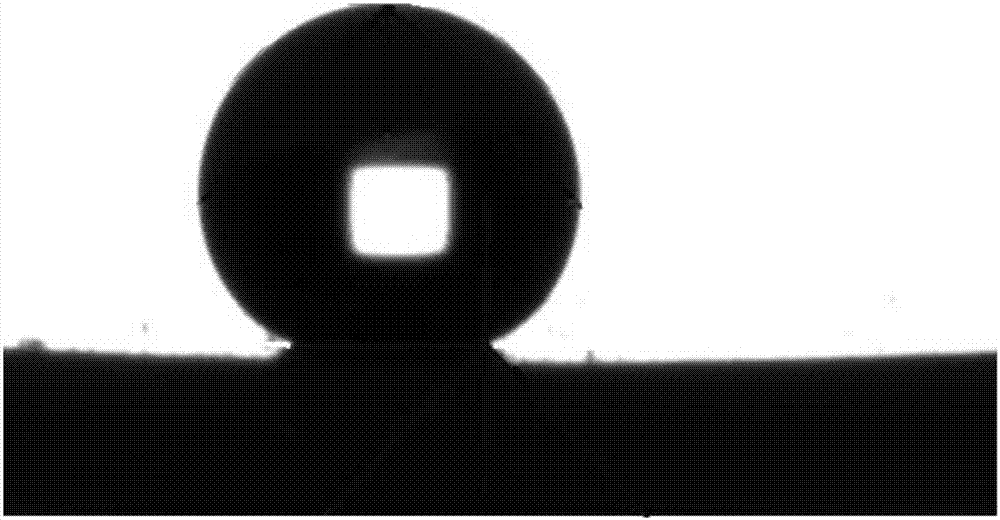

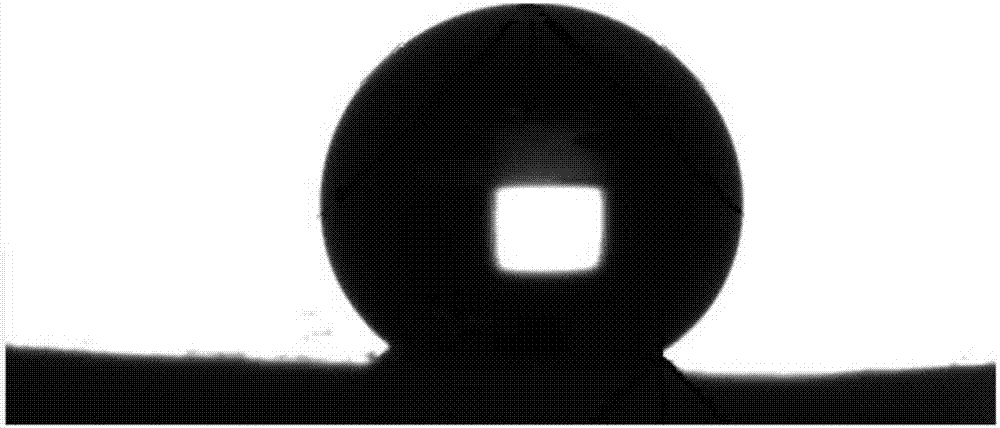

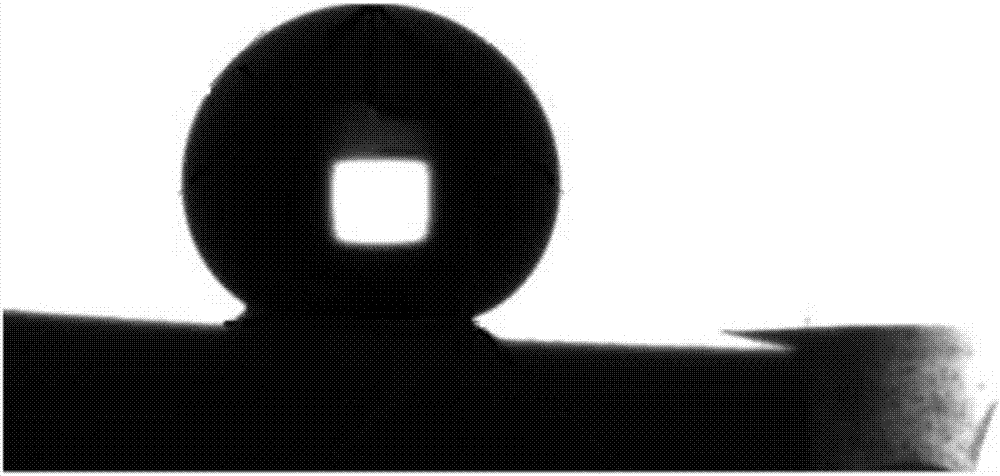

Image

Examples

specific Embodiment approach 1

[0033] Specific implementation mode 1: In this implementation mode, a method of reverse extraction with organic solvents is used to prepare hydrophobic SiO 2 The method for airgel material, it is carried out according to the following steps:

[0034] 1. Preparation of gel precursor:

[0035] Mix the silicon source with 0.1-18mol / L acid solution at a molar ratio of 1:0.001-10, place it in an ultrasonic instrument or a microwave machine, and react at a temperature of 0-80°C for 1-60 minutes; Add ammonia water to the liquid, continue ultrasonication or microwave for 1-10 minutes at a temperature of 0-80°C to obtain a gel precursor; the concentration of the ammonia water is 0.5-10mol / L;

[0036] Wherein, the silicon source is methyltrimethoxysilane, ethyltrimethoxysilane, propyltrimethoxysilane, isobutyltrimethoxysilane, octyltrimethoxysilane, dimethyldimethoxysilane, Methyltriethoxysilane, Ethyltriethoxysilane, Propyltriethoxysilane, Isobutyltriethoxysilane, Octyltriethoxysilan...

specific Embodiment approach 2

[0044] Embodiment 2: This embodiment is different from Embodiment 1 in that the silicon source is a mixture of propyltrimethoxysilane and tetraethoxysilane in a molar ratio of 1:0.1-10. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0045] Embodiment 3: This embodiment is different from Embodiment 1 in that the silicon source is a mixture of propyltrimethoxysilane and tetraethoxysilane in a molar ratio of 1:0.2-10. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com