Method for preparing Ag/g-C3N4 catalyst

A g-c3n4, catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, hydrogen production, etc., can solve problems such as influence and reduce photocatalytic efficiency, and achieve simple process, good repeatability, and yield. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A. Weigh 10 g of urea and dissolve it in 40 ml of distilled water and ultrasonicate for 20 minutes to obtain solution A.

[0029] B. Heat the obtained solution A in a water bath at 90°C with constant stirring until it evaporates to dryness quickly, and then put it into an oven at 60°C to dry to obtain sample B.

[0030] C. Put sample B in a round crucible, cover the crucible and place it horizontally in the muffle furnace, ensuring that the initial temperature of the muffle furnace is less than 80 degrees Celsius.

[0031] D. Raise the temperature of the muffle furnace to 550°C at a rate of 2.3°C per minute, and keep it at this temperature for 4 hours to obtain sample C.

[0032] E. Naturally cool to room temperature, wash sample C with deionized water and absolute ethanol three times respectively, and then dry in an oven at 60°C for 12 hours to obtain pure g-C 3 N 4 .

Embodiment 2

[0034] A. Weigh 10 g of urea and dissolve it in 40 ml of distilled water and ultrasonicate for 20 minutes to obtain solution A.

[0035] B. Add 0.03gAgNO 3 Added to solution A, and stirred in the air for 20min to obtain solution B.

[0036] C. Heat the obtained solution B in a water bath at 90°C with constant stirring until it evaporates to dryness quickly, and then dry it in an oven at 60°C to obtain sample C.

[0037] D. Put sample C in a circular crucible, cover the crucible and place it horizontally in the muffle furnace to ensure that the initial temperature of the muffle furnace is less than 80 degrees Celsius.

[0038] E. Raise the temperature of the muffle furnace to 550°C at a rate of 2.3°C per minute, and keep it at this temperature for 4 hours to obtain sample D.

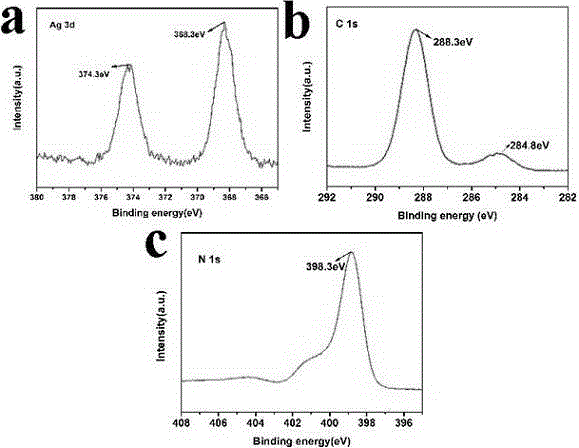

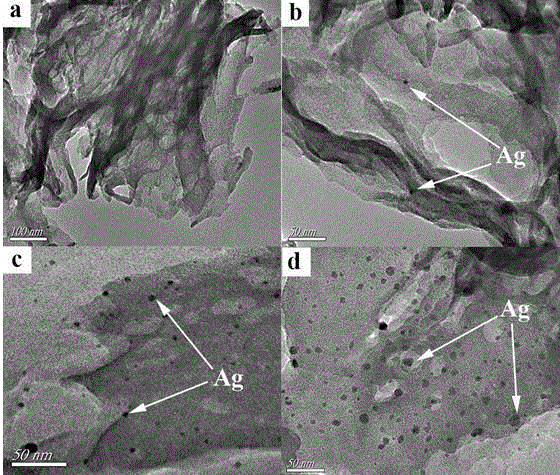

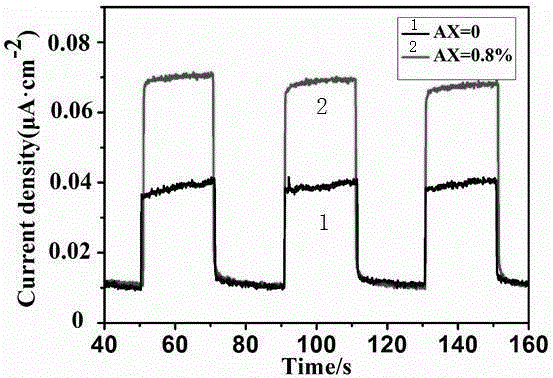

[0039] F. Naturally cool to room temperature, wash sample D with deionized water and absolute ethanol 3 times respectively, and then dry in a 60°C oven for 12h to obtain Ag quantum dot-modified g-C 3 N...

Embodiment 3

[0041] A. Weigh 10 g of urea and dissolve it in 40 ml of distilled water and ultrasonicate for 20 minutes to obtain solution A.

[0042] B. Add 0.08gAgNO 3 Added to solution A, and stirred in the air for 20min to obtain solution B.

[0043]C. Heat the obtained solution B in a water bath at 90°C with constant stirring until it evaporates to dryness quickly, and then dry it in an oven at 60°C to obtain sample C.

[0044] D. Put sample C in a circular crucible, cover the crucible and place it horizontally in the muffle furnace to ensure that the initial temperature of the muffle furnace is less than 80 degrees Celsius.

[0045] E. Raise the temperature of the muffle furnace to 550°C at a rate of 2.3°C per minute, and keep it at this temperature for 4 hours to obtain sample D.

[0046] 、 Naturally cooled to room temperature, sample D was washed three times with deionized water and absolute ethanol, and then dried in an oven at 60°C for 12 h to obtain Ag quantum dot-modified g-C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com