Improved treatment method of acidic waste water containing heavy metals

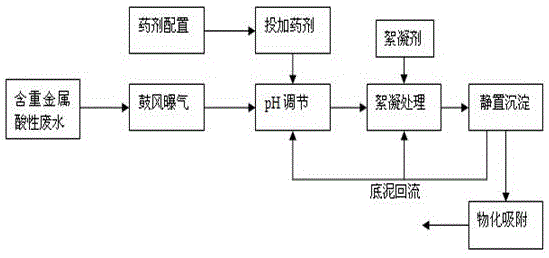

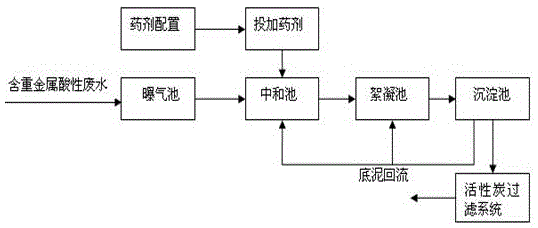

A technology of acid wastewater and treatment method, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of complex treatment process, high moisture content of sediment and high treatment cost , to achieve the effect of simple production process, reduced sludge volume, and reduced pipeline blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further describe the present invention, an improved method for treating heavy metal-containing acidic wastewater of the present invention will be described in more detail below in conjunction with examples.

[0027] The method of the invention is used to treat heavy metal-containing acid wastewater discharged from a certain mine dump in East China. The water quality of the heavy metal-containing acid wastewater discharged from the dump is shown in Table 1.

[0028] sample pH Cu 2+ Fe 3+ Zn 2+ SO4 2- content 2.8 30-400 300-500 10-30 3240

[0029] The treatment process, steps and technical parameters are as follows:

[0030] (1) Blast aeration: The acidic wastewater containing heavy metals in the mine is blown and aerated for oxidation treatment in the aeration tank, and the aeration time is 40 minutes; the aeration system adopts ceramic microporous aeration heads.

[0031] (2) pH adjustment: the wastewater after aeratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com