Aeration biological filter chamber facility

A biological aerated filter and filter technology, applied in aerobic and anaerobic process treatment and other directions, can solve the problems of unstable removal of organic matter, nitrogen and phosphorus removal, unreasonable flushing method, and reduced biofilm activity, etc. Achieve the effect of small footprint, wide application range and less residual sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

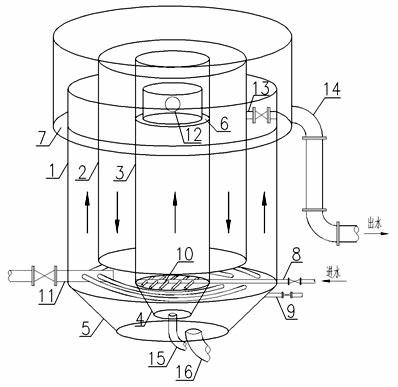

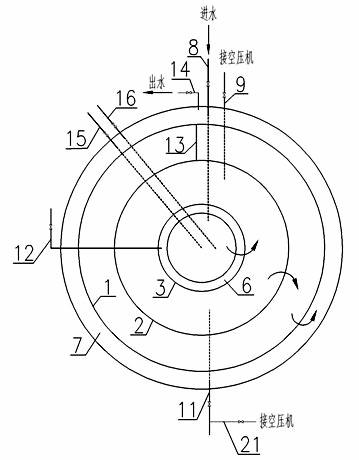

[0014] Refer to attached figure 1 and figure 2 , the equipment adopts a cylindrical stainless steel pool, the circular pool is isotropic, the stress conditions and hydraulic conditions are very good, and it occupies a small area. Under the condition of the same volume, it saves the most materials, and there are only two pools Welding seam, the probability of equipment problems is lower than that of conventional square pools.

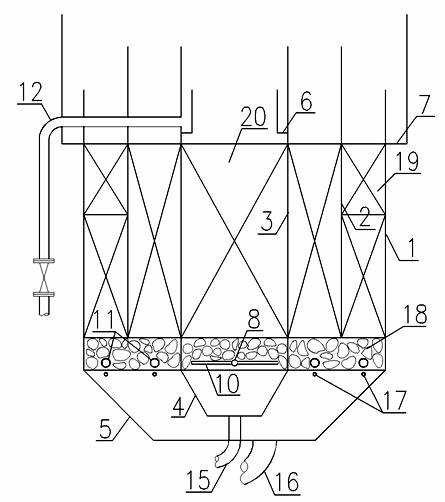

[0015] The interior of the equipment is divided into three filters from the inside to the outside by two concentric cylinders, which are the anoxic zone filter 3, the first aerobic zone filter 2 and the second aerobic zone filter 1. Each zone filter is filled with enzymatic biological filler 20 with corresponding particle size distribution. Among them, the anoxic zone filter 3 mainly plays the role of intercepting suspended solids in wastewater and hydrolytic acidification, the first aerobic zone filter 2 mainly plays the role of oxidizing and decompo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com