Biochemical treatment method of acrylic ester industrial wastewater

A biochemical treatment and acrylate technology, applied in biological water/sewage treatment, natural water treatment, chemical instruments and methods, etc., can solve the problems of high operating cost and affect the economic benefits of enterprises, reduce floor space, intercept suspended The effect of strong physical ability and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

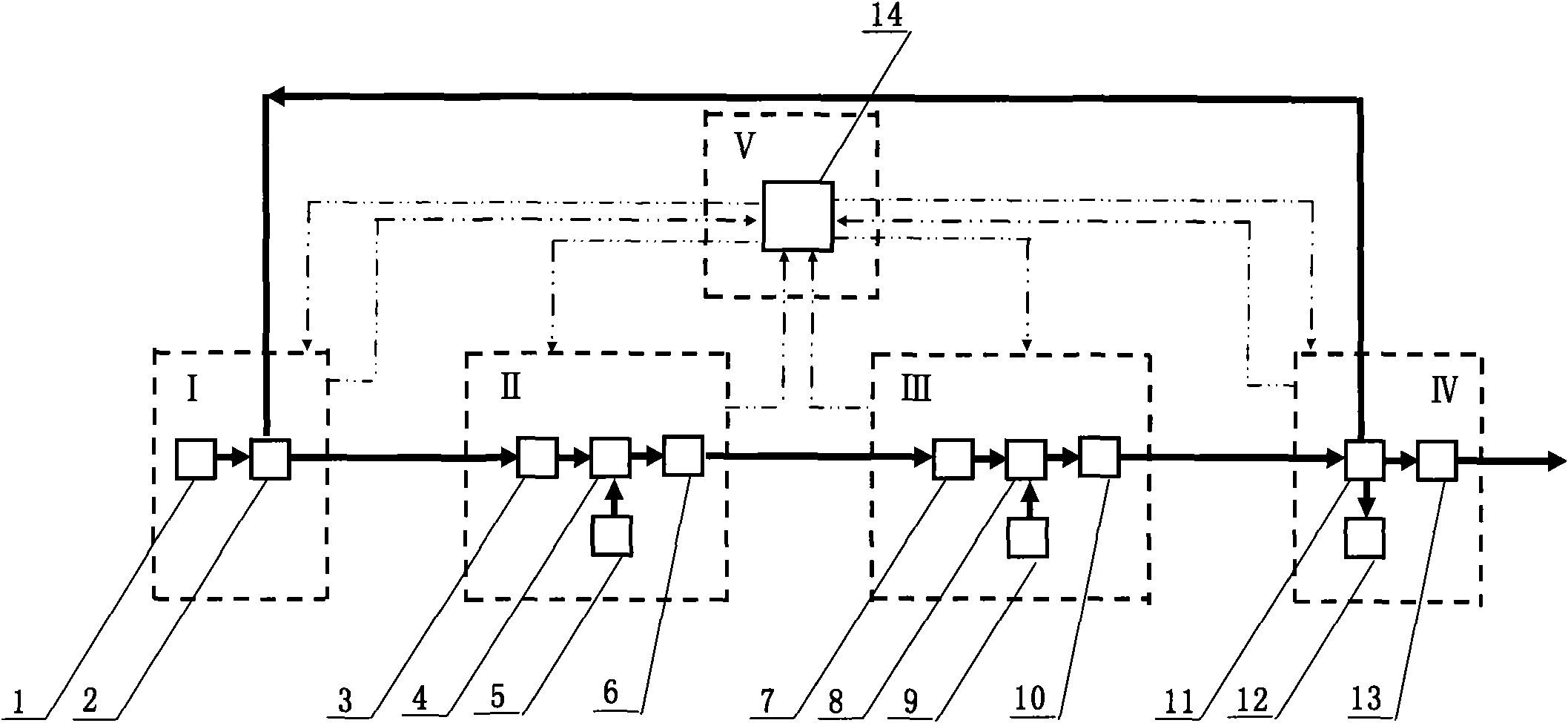

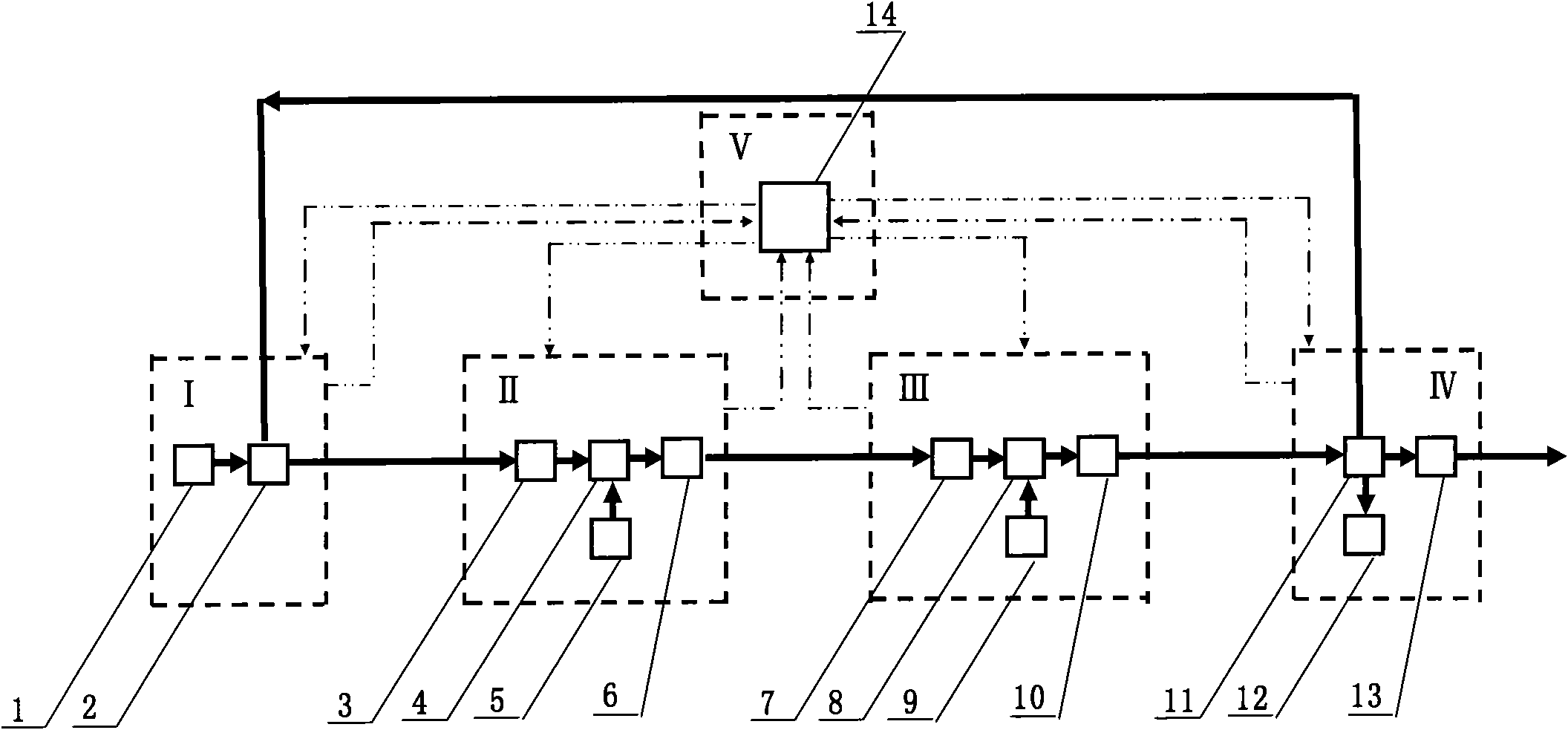

[0029] Depend on figure 1 As shown, the pretreatment step is carried out in the wastewater pretreatment system I, and the wastewater pretreatment system I includes wastewater collecting equipment 1 and wastewater regulating equipment 2 . The acrylate wastewater generated from the production equipment is first collected and stored by the wastewater collection equipment 1; then it is pumped to the wastewater adjustment equipment 2, and the COD and salt content of the wastewater are adjusted by using the clear water sent back from the flocculation sedimentation tank 11, and adjusted by lye The PH value of the wastewater uses steam to adjust the temperature of the wastewater. The purpose of the wastewater conditioning equipment 2 is to reduce the fluctuation of the wastewater quality and flow, so that the microorganisms in the rear can live in the best state, and provide the best conditions for the subsequent biochemical treatment. The outlet of the waste water regulating equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com