Cement stabilizing soil based on regenerated concrete aggregates in different quality grades

A technology of cement stabilized soil and quality grade, applied in the field of cement stabilized soil, can solve the problems of occupying land, surrounding environmental pollution, waste of resources, etc., and achieve the effects of being beneficial to agricultural production and environmental protection, reducing construction costs, and improving living conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

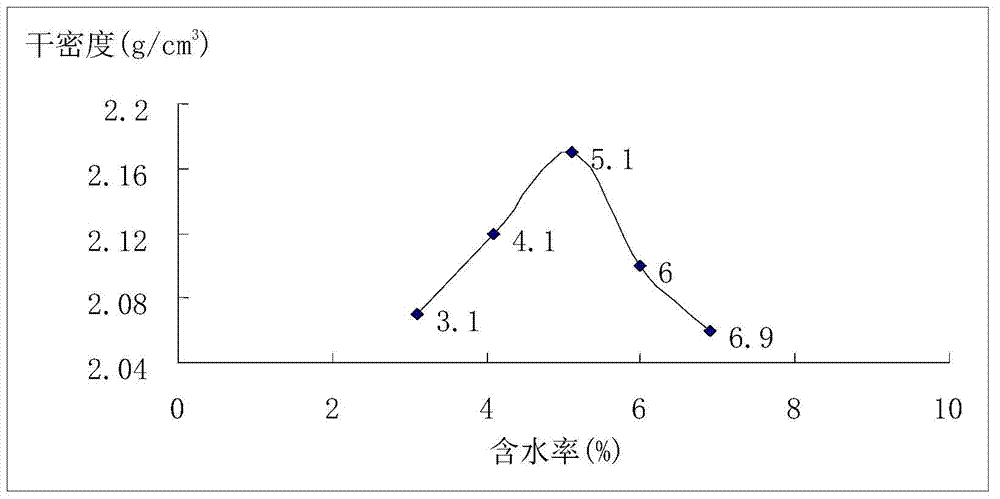

[0040] Example 1: The mixing ratio is: 90% of recycled grade I aggregate: 4% of cement: 6% of fly ash.

[0041] Table 5.1 The first set of compaction test data

[0042] Moisture contentω%

3.1

4.1

5.1

6.0

6.9

Dry density ρg / cm 3

2.07

2.12

2.17

2.10

2.06

[0043] Conclusion: drawn by compaction curve (see the attached figure for details) figure 1 ) can get the optimal water content ω of the first group 0 =5.2%, the corresponding maximum dry density ρ dmax =2.17.

[0044] Table 5.2 Unconfined Compressive Strength Test Record Form of Cement Stabilized Soil

[0045]

Embodiment 2

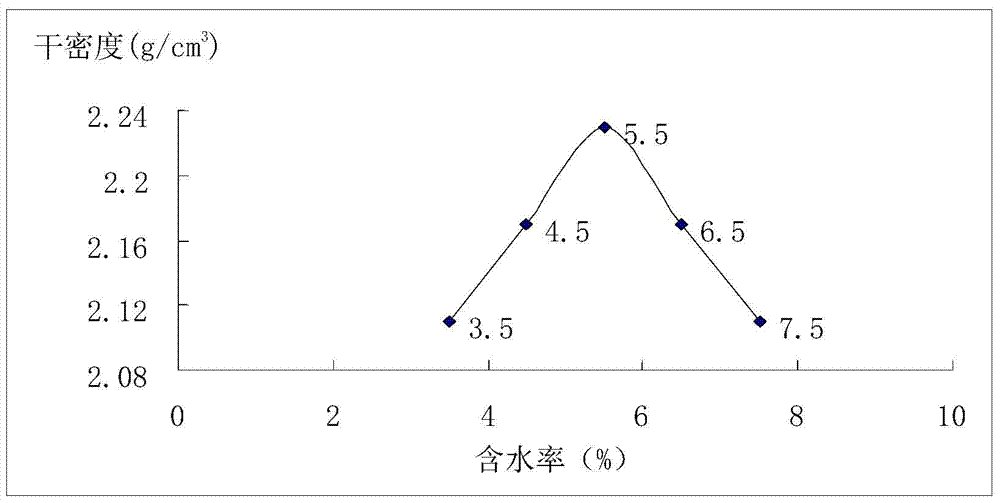

[0046] Example 2: The mixing ratio is: 88% of recycled grade II aggregate: 5% of cement: 7% of fly ash.

[0047] Table 6.1 The second set of compaction test data

[0048] Moisture contentω%

3.5

4.5

5.5

6.5

7.5

Dry density ρg / cm 3

2.11

2.17

2.23

2.17

2.11

[0049] Conclusion: drawn by compaction curve (see the attached figure for details) figure 2 ) can get the optimal water content of the second group ω 0 =5.4%, the corresponding maximum dry density is ρ dmax =2.23.

[0050] Table 6.2 Unconfined compressive strength test record table of the second group of cement-stabilized soil

[0051]

Embodiment 3

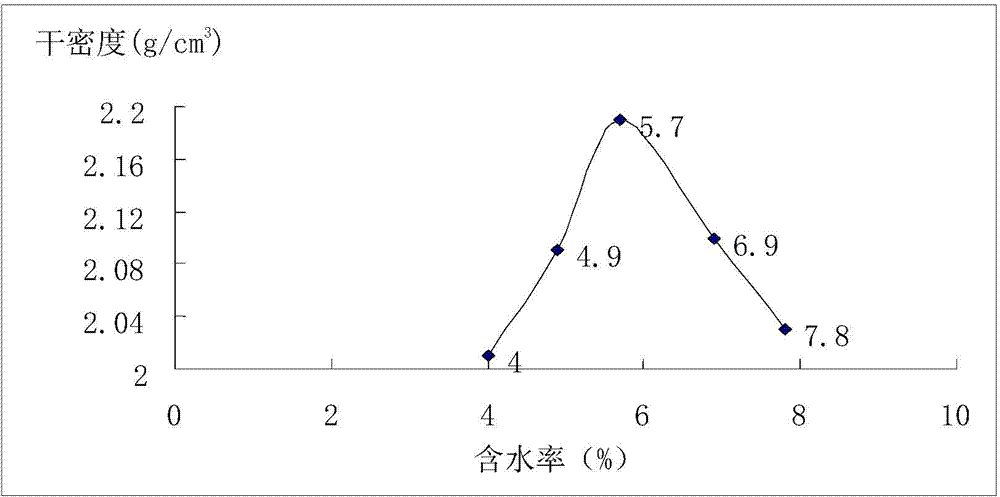

[0052] Example 3: The mixing ratio is: 85% of recycled grade II aggregate: 6% of cement: 9% of fly ash.

[0053] Table 7.1 The third group of compaction test data

[0054] Moisture contentω%

4.0

4.9

5.7

6.9

7.8

Dry density ρg / cm3

2.01

2.09

2.19

2.1

2.03

[0055] Conclusion: drawn by compaction curve (see the attached figure for details) image 3 ) can get the optimum water content ω of the third group 0 =6.0%, the corresponding maximum dry density ρ dmax =2.19.

[0056] Table 7.2 Unconfined compressive strength test record table of the third group of cement-stabilized soil

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com