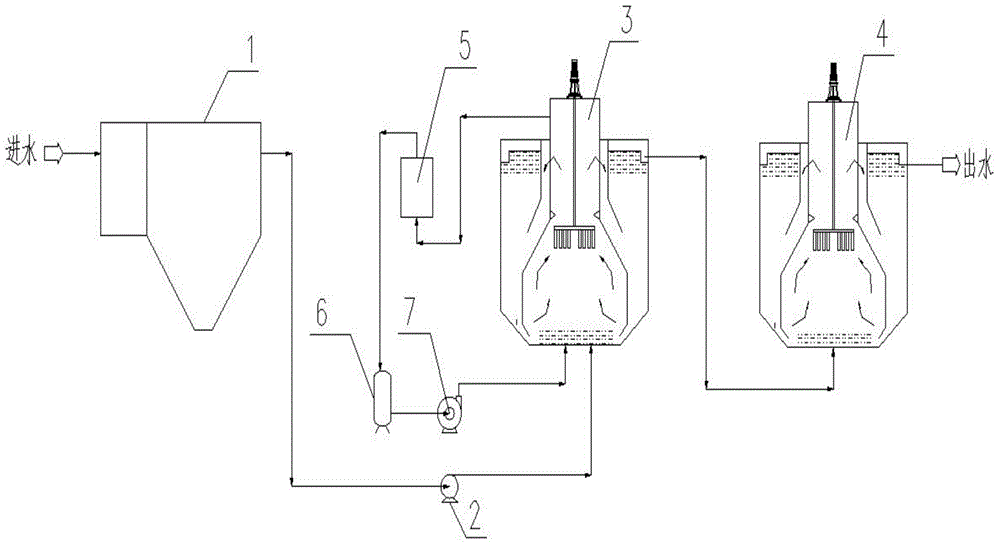

Acidic high sulfate organic wastewater treatment process and apparatus

A high-sulfate, organic wastewater technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the limitations of poor stability, limited treatment effect, and high-concentration sulfate wastewater and other problems, to achieve the effect of strong impact load resistance, human body safety and non-toxicity, and power consumption saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The raw water quality of sulfate-containing acidic organic saponin wastewater is as follows: pH=1-2, CODcr is 20000-25000mg / l, [SO 4 2- ] is 5000-8000 mg / l. The waste water first enters the neutralization sedimentation tank 1, and by adding lime milk Ca(OH) 2 Adjust the pH of wastewater to 7.5-8 so that [Ca 2+ ] dosage and [SO 4 2- ] molar ratio > 1.2, fully stirred and reacted for 20min, so that SO 4 2- with Ca 2+ The reaction forms slightly soluble CaSO 4 Precipitation, in order to increase the precipitation rate and SO 4 2- Removal efficiency, while adding AlCl 3 and PAM, the dosage is 200mg / l and 3mg / l respectively, and then the CaSO 4 Precipitate and separate from water, the sedimentation time is 4 hours, the surface load of the sedimentation tank is ≤0.5m 3 / m 2 h. Precipitated CaSO 4 Removed by sludge discharge, effluent [SO 4 2- ] about 3000-5000mg / l;

[0041] The wastewater after neutralization and precipitation treatment enters a section of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com