Treatment device with bio-sludge degrading and denitrogenation, and its operating method

A biological sludge and denitrification technology, applied in biological sludge treatment, biological water/sewage treatment, sludge treatment, etc., can solve the problems of difficult final disposal of sludge, high cost of sludge incineration, and troublesome operation. To achieve the effect of easy implementation and promotion, good sedimentation and dewatering performance, and no sludge agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

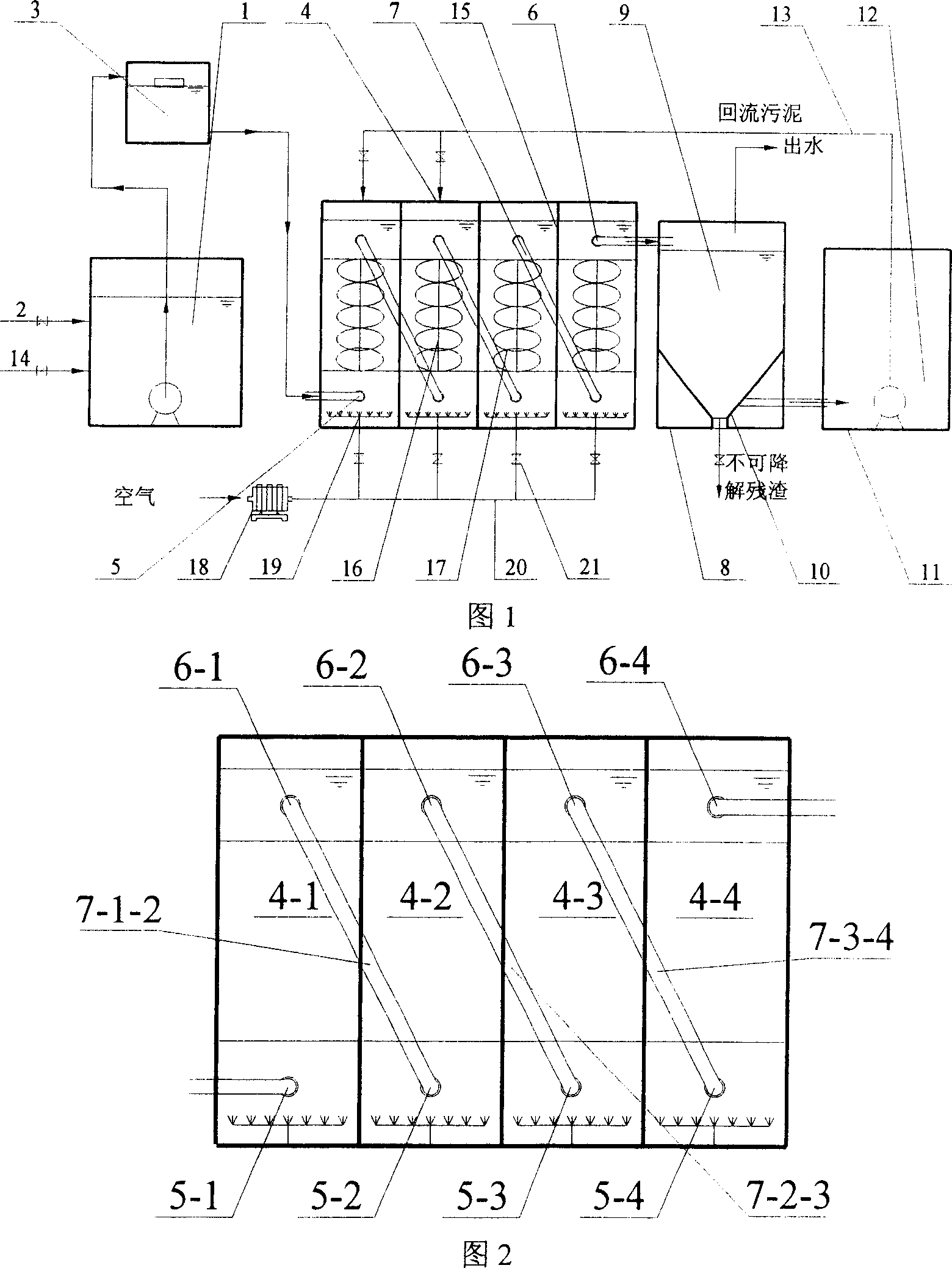

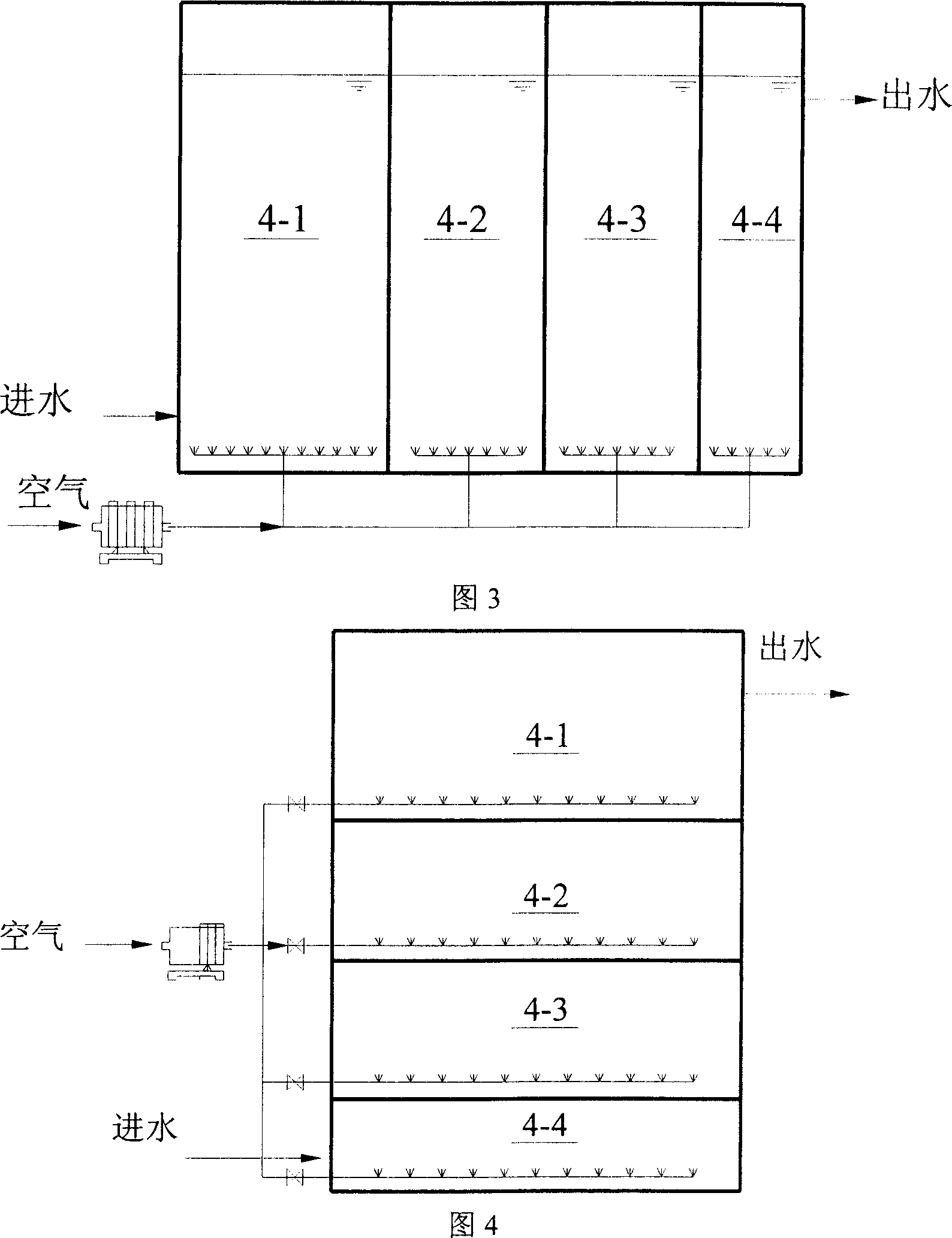

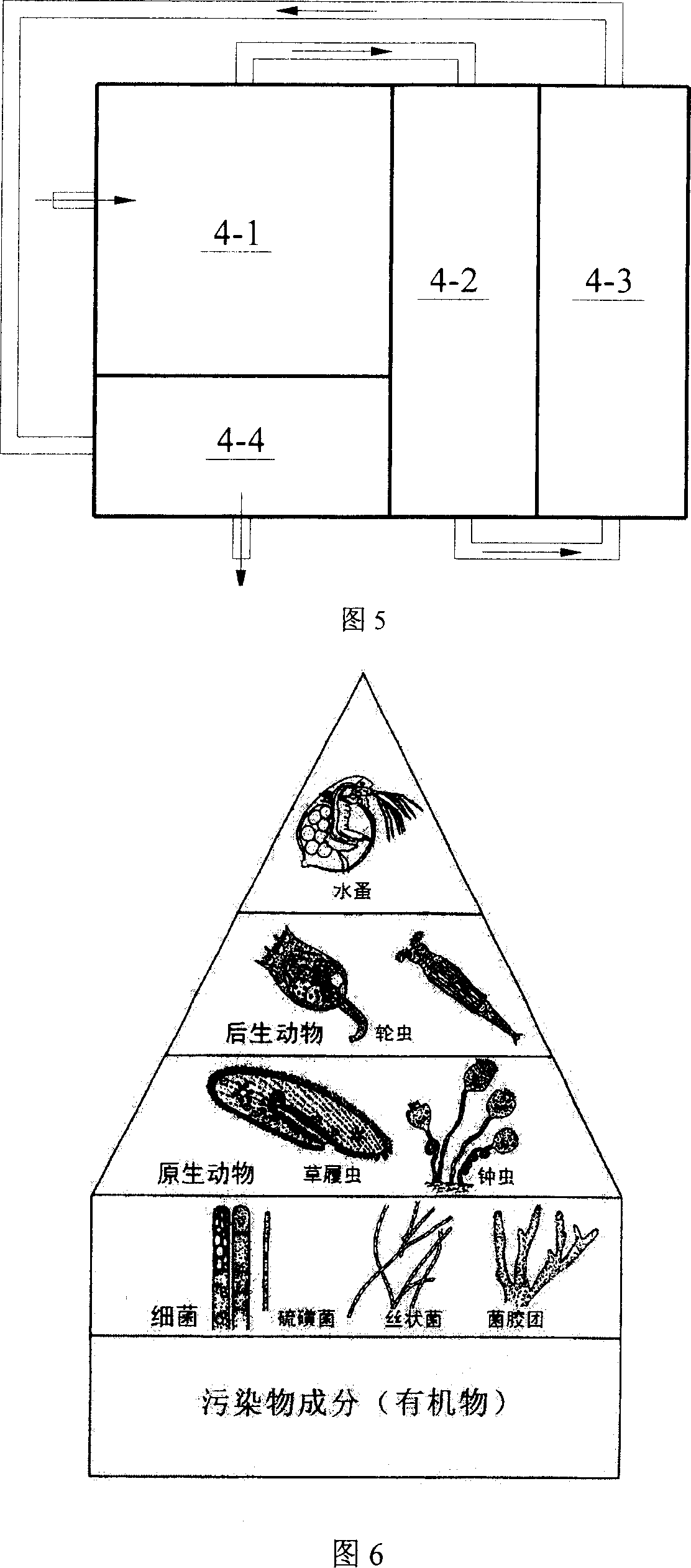

[0035] As shown in Figure 1, the excess sludge 14 retrieved from the municipal sewage plant and a small amount of dairy waste water 2 are mixed and lifted to the head tank 3 at a ratio of 2:1 to 6:1. Then it flows into the first tank 4-1 of the multi-stage oxidation tank by gravity and flows into the tanks 4-2, 4-3, 4-4, the solid-liquid separation sedimentation tank and the anaerobic tank sequentially along the water flow direction. During the whole operation process, the water temperature in the multi-stage oxidation tank is kept at 20-25°C, the pH is 6-9, and the activated sludge concentration in the first tank is 5.5-6.5g / L. After the muddy water mixture at the outlet of the fourth tank settles in the solid-liquid separation sedimentation tank 8, the supernatant 9 is discharged, and the remaining sludge 10 at the bottom of the solid-liquid separation sedimentation tank is hydrolyzed by the adjacent anaerobic hydrolysis tank 11. The sludge 12 flows back along the sludge ret...

Embodiment 2

[0038] The excess sludge 14 retrieved from the urban sewage plant and a small amount of dairy waste water 2 are mixed and lifted to the head tank 3 in a ratio of 2:1-6:1. Then it flows into the first tank 4-1 of the multi-stage oxidation tank by gravity and flows into the tanks 4-2, 4-3, 4-4, the solid-liquid separation sedimentation tank and the anaerobic tank sequentially along the water flow direction. During the whole operation process, the water temperature in the multi-stage oxidation tank is kept at 20-25°C, the pH is 6-9, and the concentration of activated sludge in the first tank is 5.5-6.5g / L, and the substrate concentration and supply of each tank are flexibly controlled. oxygen conditions. After the mud-water mixture at the water outlet of the fourth tank settles in the solid-liquid separation and sedimentation tank 8, the supernatant 9 is discharged, and the reflux method of the remaining sludge 10 at the bottom of the solid-liquid separation and sedimentation t...

Embodiment 3

[0043] The biological sludge treatment device of the present invention can also be used to treat wastewater with high nitrogen content. Put the dairy product wastewater with a total nitrogen concentration of 36.3-92.2mg / L and an ammonia nitrogen concentration of 30.1-52.1mg / L into the adjustment tank 1, then lift it to the high-level tank 3, and then flow into the first tank of the multi-stage oxidation tank by gravity 4-1 and flow into 4-2, 4-3, 4-4 tanks, solid-liquid separation sedimentation tank, and anaerobic tank sequentially along the water flow direction. During the whole operation process, the water temperature in the multi-stage oxidation tank is kept at 20-25°C, the pH is 6-9, and the activated sludge concentration in the first tank is 5.5-6.5g / L. After the mud-water mixture at the water outlet of the fourth tank is settled 8, the supernatant 9 is discharged, and the reflux method of the remaining sludge 10 at the bottom of the solid-liquid separation and sedimentat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com