Coked and petrochemical wastewater treatment process having deep biochemical treatment and physicochemical treatment

A petrochemical wastewater treatment technology, applied in chemical instruments and methods, flotation water/sewage treatment, water/sludge/sewage treatment, etc. Water quality requirements and other issues, to achieve good shock load resistance, strong shock load resistance, and achieve the effect of unmanned operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

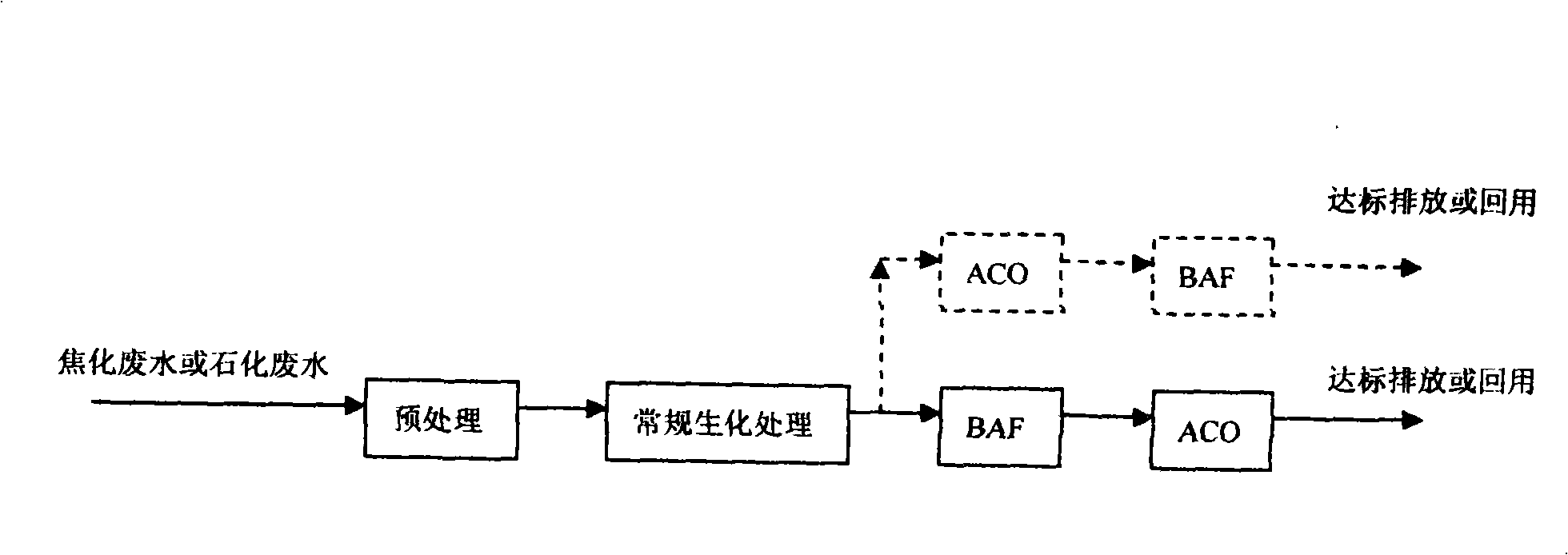

[0015] exist figure 1 Among them, the coking wastewater and petrochemical wastewater are pretreated first, and the pretreated coking wastewater and petrochemical wastewater are then subjected to conventional biochemical treatment. Advanced chemical oxidation tank treatment after treatment in the pool, and finally discharged up to standard; or advanced chemical oxidation tank treatment first to improve the biodegradability of wastewater, and then alternate and repeated filtration and backwashing with biological aerated filter, and finally discharged up to standard .

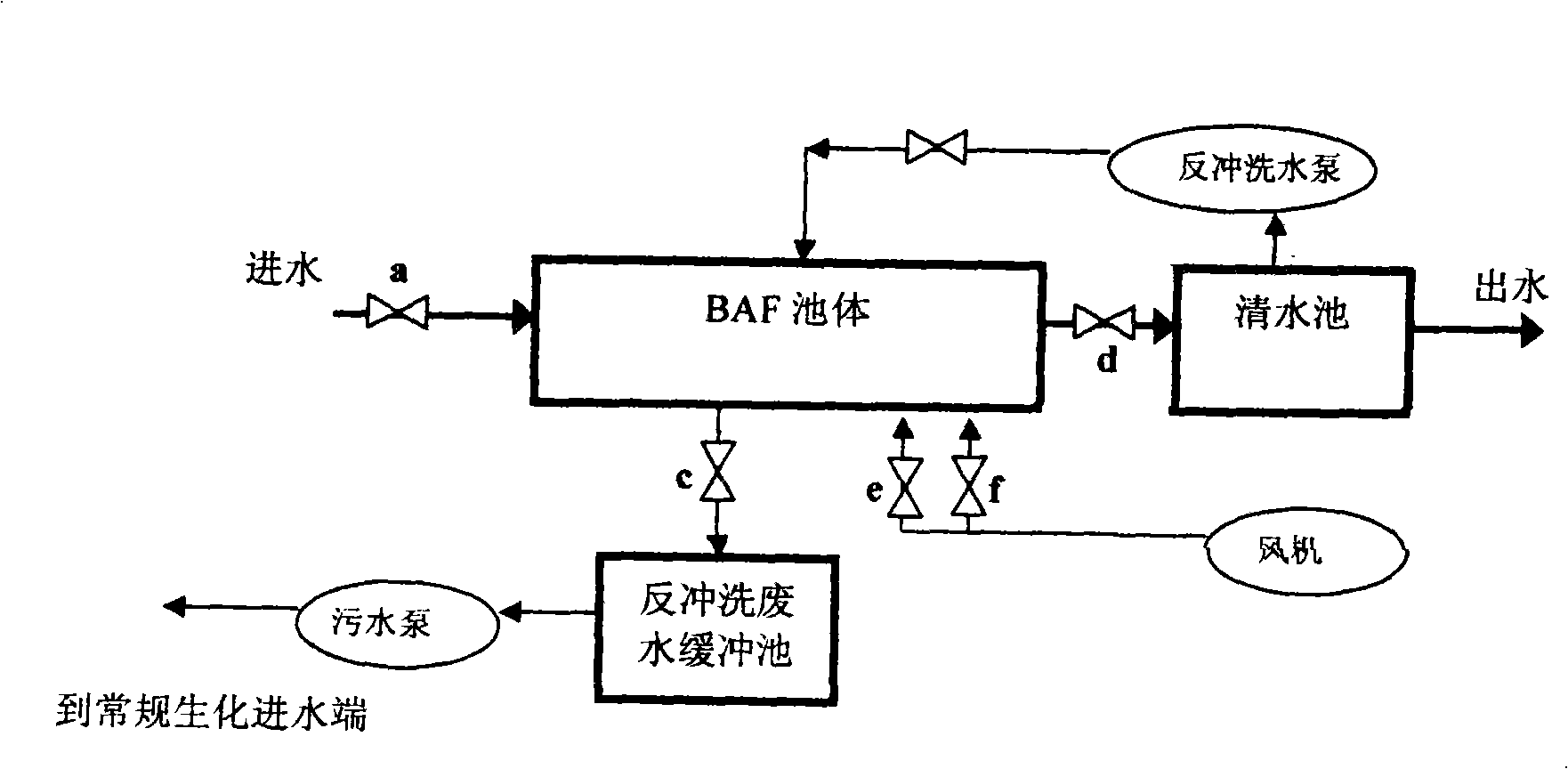

[0016] exist figure 2 Among them, biological aerated filter (BAF) is a complete system, which consists of BAF tank body, valves, pipes, pumps, fans, automatic control system, backwash storage tank and backwash wastewater tank, etc. The schematic diagram of the BAF treatment process is shown in figure 2 . Its operation mode is that the two stages of filtration and backwashing are carried out alternately and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com