Technique of biological treatment for wastewater of carbonization

A technology for coking wastewater and biological treatment, applied in sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. Difficulty in reaching the target, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

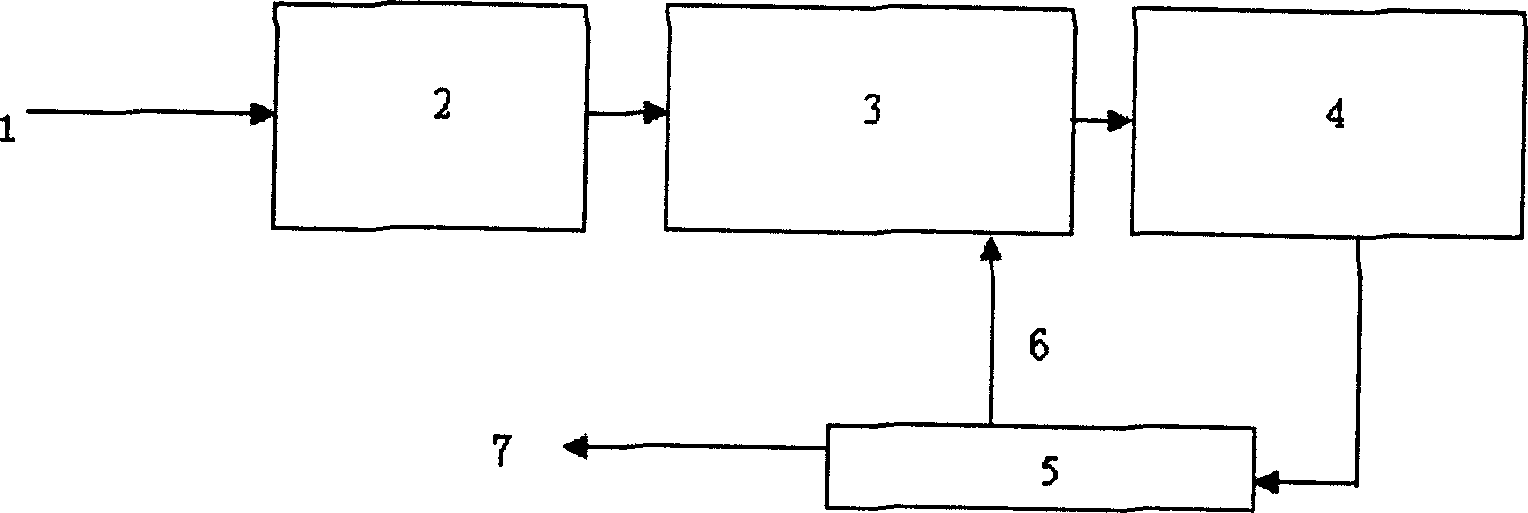

Image

Examples

Embodiment approach 1

[0030] Embodiment 1: Anaerobic hydrolysis acidification reactor hydraulic retention time 4h;

[0031] Upflow anoxic reactor hydraulic retention time 9h;

[0032] Biological contact oxidation pond hydraulic retention time 12h;

[0033] Biological aerated filter hydraulic retention time 12h;

[0034] The effluent from the upflow biological aerated filter flows back to the anoxic packed reactor with a reflux ratio of 2:1.

Embodiment approach 2

[0035] Embodiment 2: Anaerobic hydrolysis acidification reactor hydraulic retention time 6h;

[0036] Upflow anoxic reactor hydraulic retention time 15h;

[0037] Biological contact oxidation tank hydraulic retention time 18h;

[0038] Biological aerated filter hydraulic retention time 24h;

[0039] The effluent from the upflow biological aerated filter is returned to the anoxic packed reactor with a reflux ratio of 4:1.

Embodiment approach 3

[0040] Embodiment 3: Anaerobic hydrolysis acidification reactor hydraulic retention time 12h;

[0041] Upflow anoxic reactor hydraulic retention time 30h;

[0042] Biological contact oxidation tank hydraulic retention time 35h;

[0043] Biological aerated filter hydraulic retention time 35h;

[0044] The effluent from the upflow biological aerated filter is returned to the anoxic packed reactor with a reflux ratio of 4:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com