Device for treating oil field waste water

A technology for oilfield wastewater and wastewater pools, applied in water/sewage treatment, mining wastewater treatment, multi-stage water/sewage treatment, etc., can solve the problems of poor removal of pollutants in water, difficulty in recycling, high cost of magnetic seeds, etc. Achieve the effects of small footprint, good operability and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

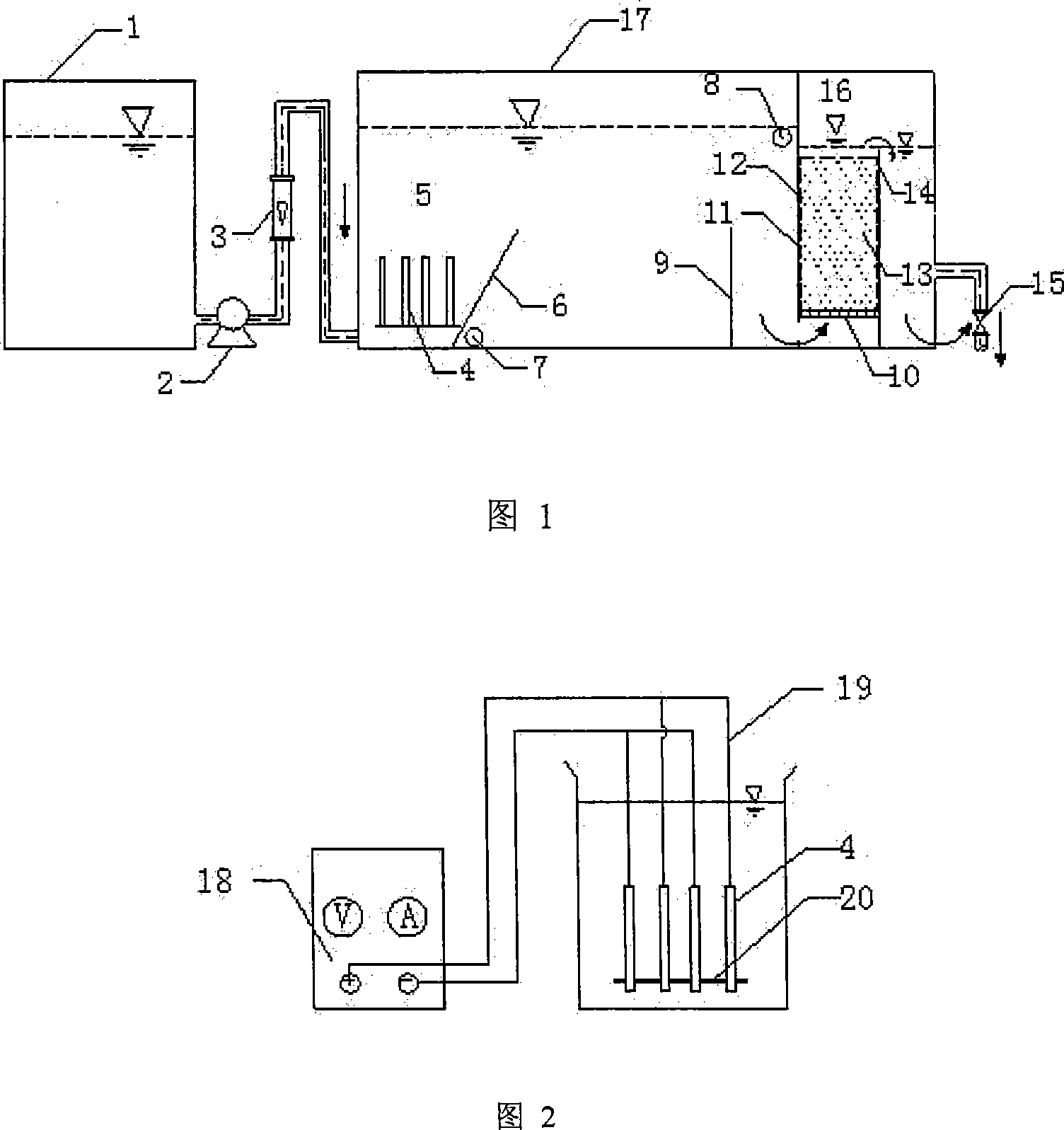

[0022] The oil field waste water in the waste water pool 1 enters the electrical floating area 5 through the water inlet pump 2, and the flow meter 3 measures the water inlet flow. The voltage and current of the electrode plate 4 is controlled by a DC stabilized power supply 18, thereby controlling the number and size of bubbles generated by electrolytic air flotation. The electrode plate 4 is fixed on the container wall with an insulating material 20, and the distance between the electrode plates is 1-2 cm. Electrolytic air flotation produces a large number of micro-bubbles, and the slick oil, most of the dispersed oil and part of the emulsified oil in the wastewater float up with the micro-bubbles, adhere to the micro-bubbles and are brought to the water surface, and the slick oil residue and sludge enter the oil collection pipe 8. After the waste water passes through the deflector sloping plate 6 at 45-60° to the horizontal plane, it crosses the baffle plate 9, passes throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com