Oxidation ditch process with functions of preventing and controlling activated sludge bulking

A technology of activated sludge and oxidation ditch, applied in the direction of aerobic and anaerobic process treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The ditch covers a large area and low energy consumption in operation, and achieves the effects of preventing and controlling the problem of activated sludge bulking, good effluent quality, and low energy consumption in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawings and examples.

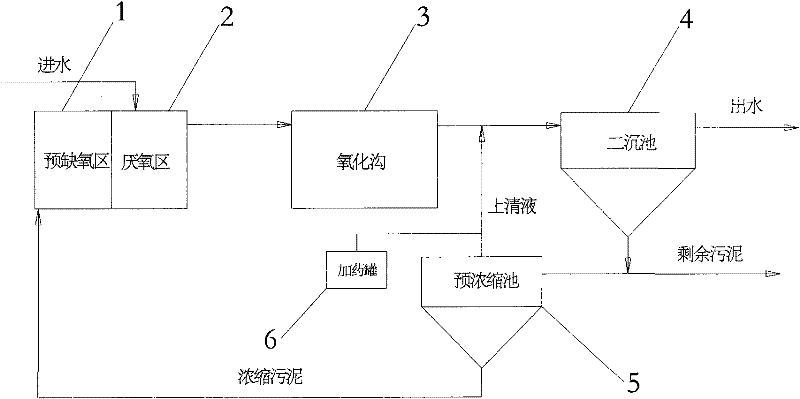

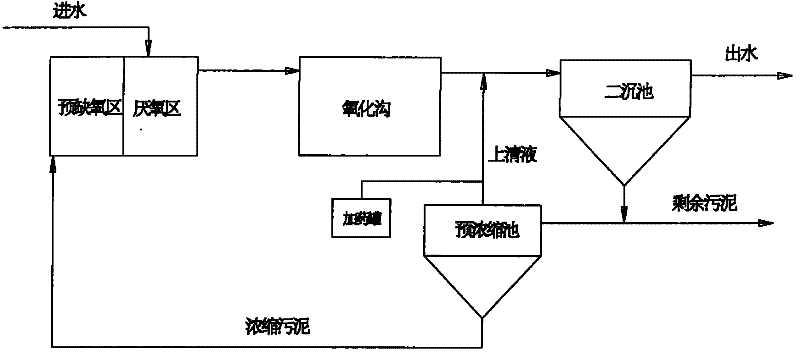

[0017] As shown in the figure, an oxidation ditch system with the function of preventing and controlling activated sludge bulking includes anaerobic zone 2, the first input of anaerobic zone 2 is connected to the system inlet, and the second input of anaerobic zone 2 The terminal is connected to the output end of the pre-anoxic zone 1, the output end of the anaerobic zone 2 is connected to the input end of the oxidation ditch 3, and the output end of the oxidation ditch 3 is connected to the input end of the secondary sedimentation tank 4 through the oxidation ditch outflow channel, The upper part of the secondary settling tank 4 is provided with a water outlet, and the bottom of the secondary settling tank is provided with a sludge outlet. The outlet of the secondary settling tank 4 is connected to the system water outlet, and the sludge outlet of the secondar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com