Device and method for enriching denitrification-dependent anaerobic methane oxidation bacteria based on intermittent membrane bioreactor

A membrane bioreactor and reactor technology, applied in biochemical equipment and methods, biochemical cleaning devices, methods for supporting/immobilizing microorganisms, etc., can solve the problems of insufficient organic carbon sources, low C/N, etc., and achieve saving Effects of aeration energy consumption and carbon source, reduction of emissions, and simple operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

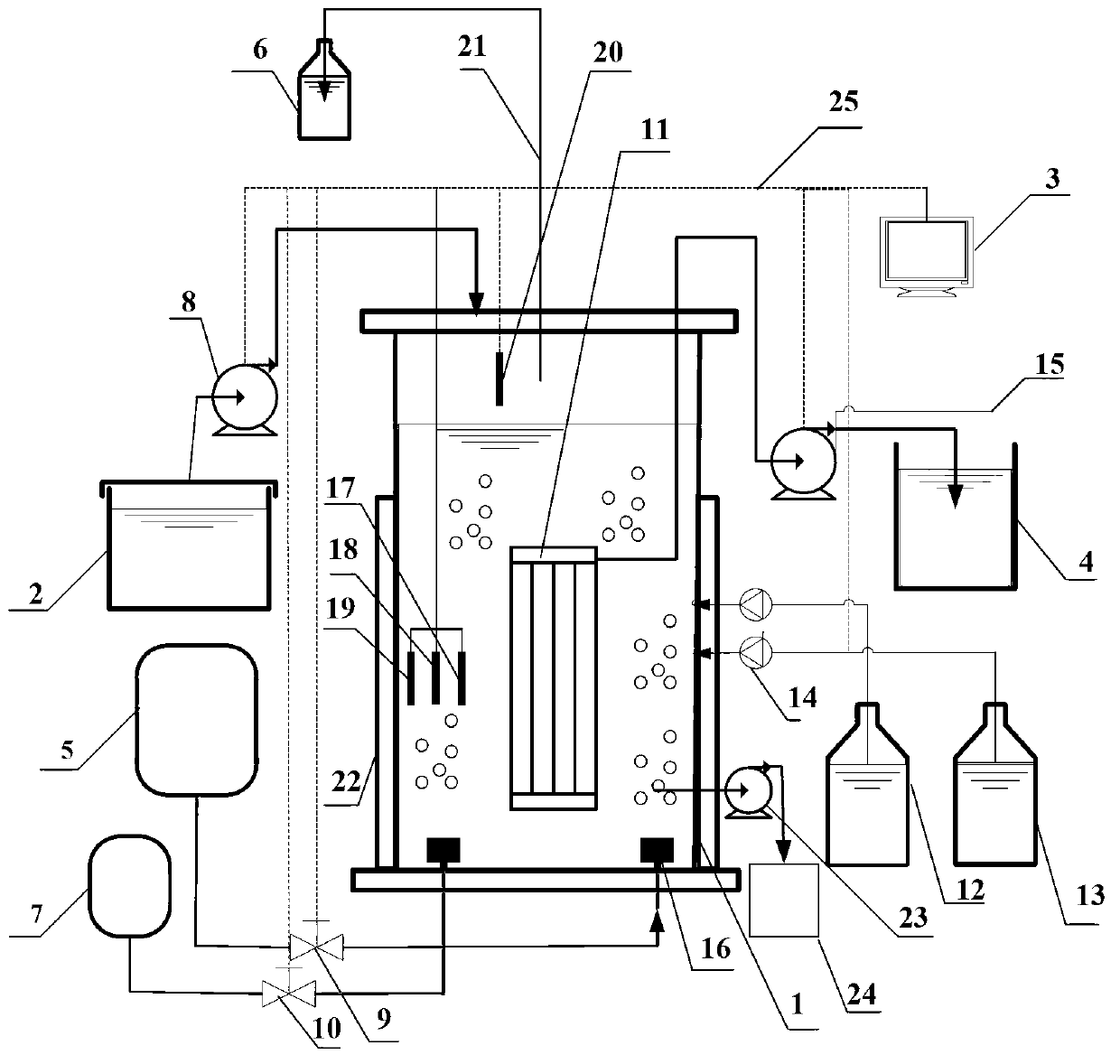

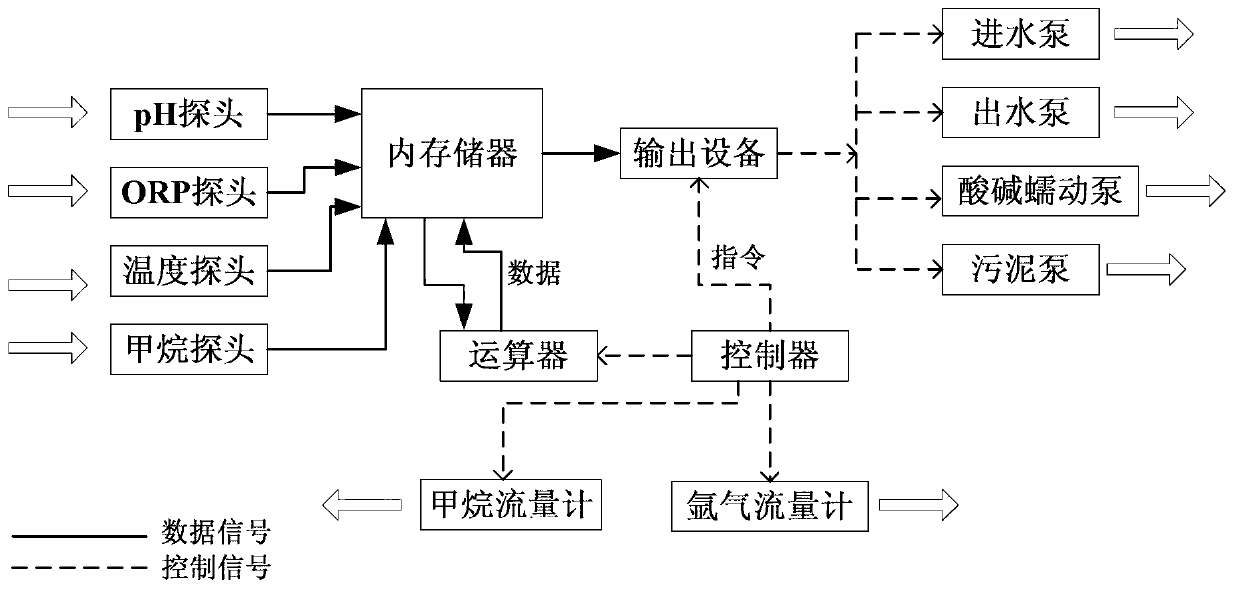

[0043] Example 1 see figure 1 As shown, a device for enriching denitrifying anaerobic methane oxidizing bacteria (N-DAMO) based on a batch membrane bioreactor (SMBR) is mainly equipped with SMBR reactor 1, and equipped with water inlet tank 2, automatic control System 3 and outlet tank 4. The water inlet tank 2 is connected to the SMBR reactor 1 through the water inlet pump 8, and the SMBR reactor 1 is provided with a hollow fiber membrane module 11 inside, and the water outlet above the upper end of the hollow fiber membrane module is connected to the outlet water pump 15 through a pipeline, and the outlet water finally enters the outlet water tank 4. The acid-base solutions in the acid buffer bottle 12 and the alkaline buffer bottle 13 are fed into the SMBR reactor 1 through the acid-base dosing peristaltic pump 14 to adjust the pH level in the SMBR reactor 1 . The methane in the methane storage tank 5 enters the SMBR reactor 1 from the aeration head 16 after the flow is a...

Embodiment 2

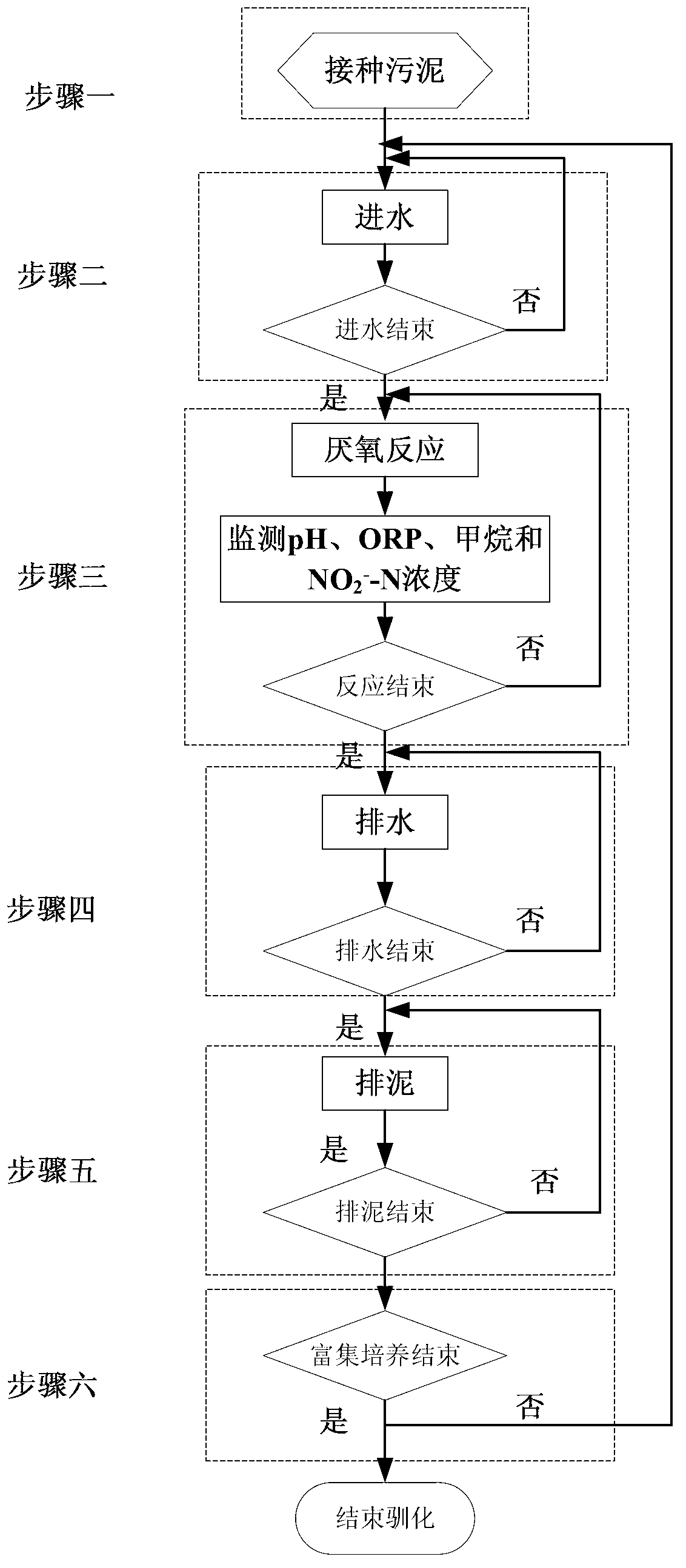

[0045] Example 2 see image 3 Shown, a kind of method based on the device of batch type membrane bioreactor enrichment denitrification type methane anaerobic bacteria, the steps are as follows:

[0046] Step 1, inoculate the sludge and wetland bottom sludge in the anaerobic sludge digester into the SMBR reactor (1) to perform intermittent domestication and cultivation of bacteria;

[0047] Step two, will contain NO 2 - -N but COD-free sewage is introduced into the SMBR reactor (1) and fully mixed with the sludge;

[0048] Step 3, open the methane gas flow meter (9) and argon gas flow meter (10) to feed methane and argon gas into the SMBR reactor (1), and the automatic control system (3) monitors and controls the denitrification anaerobic gas in real time. The change of pH and ORP value during the oxygen methane oxidation process, so that the pH is maintained between 7.0-8.0, and the ORP is maintained between -100mV and -400mV, and manual sampling is performed to monitor the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com