Method for processing paper-making waste water of regenerative paper

A treatment method and technology for papermaking wastewater, applied in biological water/sewage treatment, flotation water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as failure to meet discharge standards, excessive harmful substances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

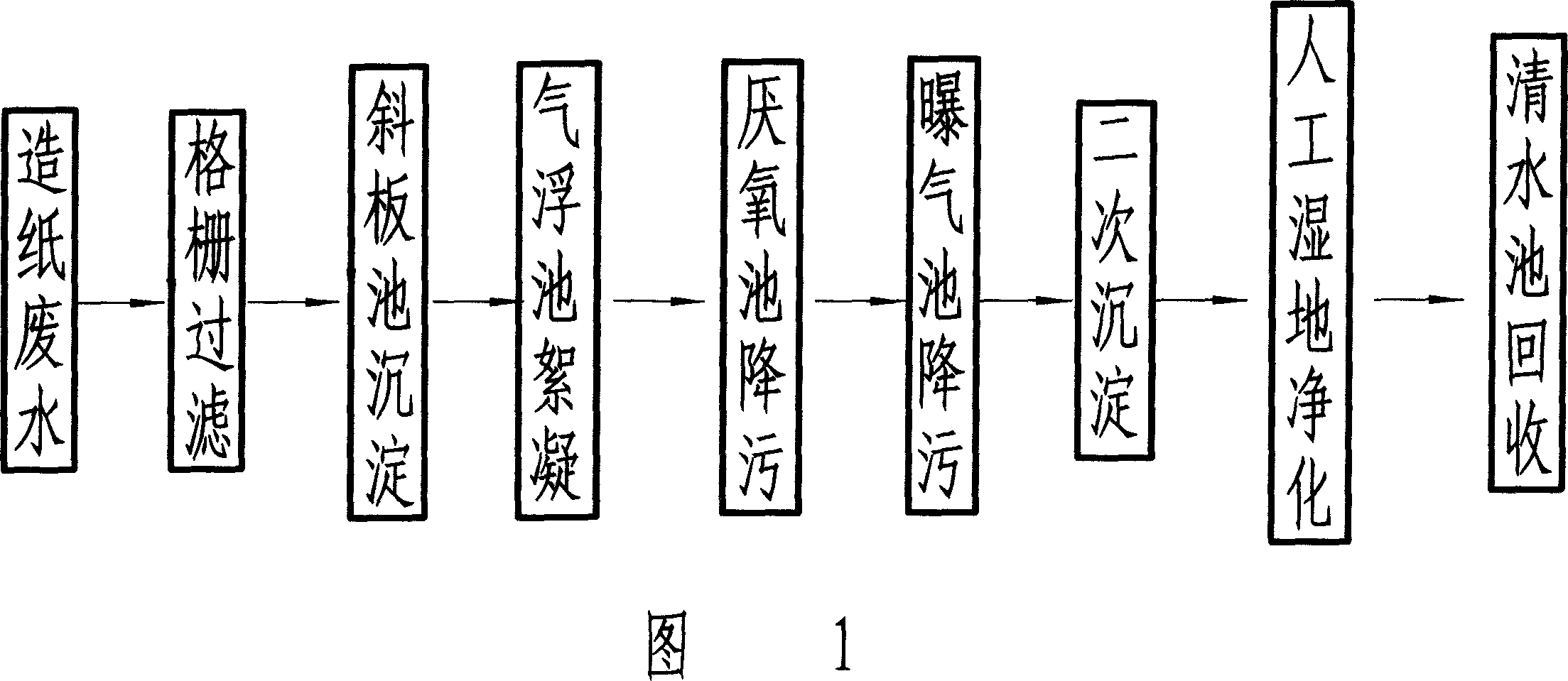

[0022] A method for treating recycled paper and papermaking wastewater, the method comprising the steps of:

[0023] (1) Use a grid with a grid pitch of 0.22mm to filter the wastewater that flows out after papermaking, and the filtered wastewater flows into the fiber recovery tank to recover fibers and other suspended matter in the wastewater; it can also be filtered with a 70-mesh nylon mesh;

[0024] (2), the waste water in the fiber recovery tank flows into the inclined plate settling tank, and the granular impurities in the waste water are removed by settling, and the settling time is 8 hours;

[0025] (3) Flow the wastewater in the inclined plate sedimentation tank into the air flotation tank, add flocculant to the air flotation tank, mix the flocculant and wastewater evenly, and condense the fine fibers in the water;

[0026] (4) Remove the suspended solids, salvage the suspended solids after the reaction of the wastewater and the flocculant in the air flotation tank to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com