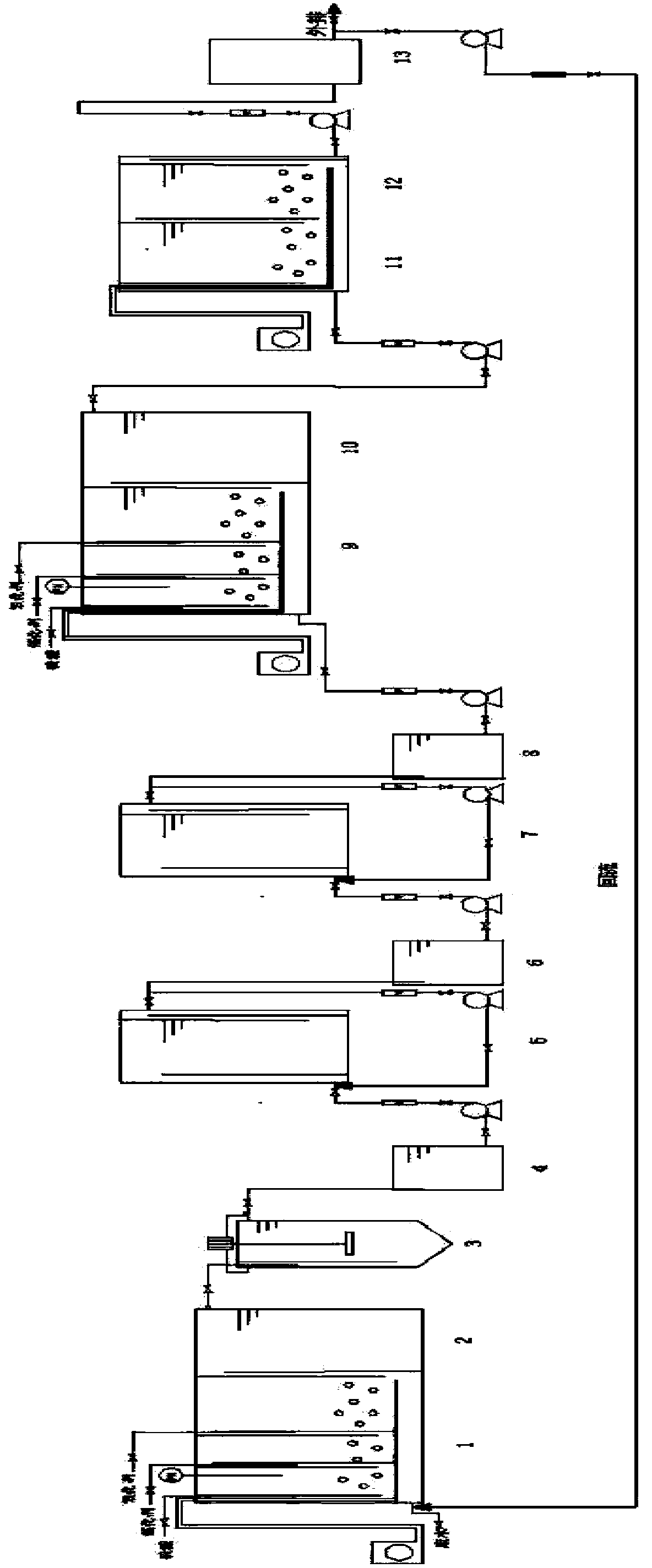

Method for disposing high-salt high-polymer wastewater through Fenton oxidation and biology combined technology

A combined process, Fenton oxidation technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of good water quality, short treatment time, and improved purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] For a drilling wastewater, the initial COD is 12000mg / L, TN is 28mg / L, TP is 78mg / L, S 2- After primary fenton oxidation, COD is 9500mg / L, TN is 28mg / L, TP is 78mg / L, S 2- After flocculation and precipitation, COD is 9500mg / L, TN is 28mg / L, TP is 18mg / L, S 2- After hydrolysis and acidification, the COD is 9000mg / L, enters the UASB anaerobic reaction device, stays for 26h, the effluent COD is 4000mg / L, TN is 27mg / L, TP is 17.5mg / L, S 2- After secondary fenton oxidation, COD is 2500mg / L, TN is 27mg / L, TP is 17.5mg / L, primary contact aerobic effluent COD is 1000mg / L, TN is 15mg / L, TP The COD of the secondary contact aerobic effluent is 450mg / L, the TN is 5mg / L, and the TP is 3g / L, reaching the COD and the third-level emission standards.

Embodiment 2

[0060] For a drilling wastewater, the initial COD is 10000mg / L, TN is 35mg / L, TP is 64mg / L, S 2- After primary fenton oxidation, COD is 8200mg / L, TN is 34mg / L, TP is 63mg / L, S 2- After flocculation and precipitation, COD is 8000mg / L, TN is 34mg / L, TP is 15mg / L, S 2- After hydrolysis and acidification, the COD is 8000mg / L, enters the UASB anaerobic reaction device, stays for 26h, the effluent COD is 3400mg / L, TN is 32mg / L, TP is 14mg / L, S 2- After secondary fenton oxidation, COD is 2000mg / L, TN is 32mg / L, TP is 14mg / L, primary contact aerobic effluent COD is 800mg / L, TN is 15mg / L, TP is 8mg / L, the COD of the secondary contact aerobic effluent is 350mg / L, the TN is 5mg / L, and the TP is 3g / L, which has reached the COD and the third-level discharge standard.

Embodiment 3

[0062] For a drilling wastewater, the initial COD is 14000mg / L, TN is 18mg / L, TP is 68mg / L, S 2- After primary fenton oxidation, COD is 10000mg / L, TN is 18mg / L, TP is 68mg / L, S 2- After flocculation and precipitation, COD is 9500mg / L, TN is 18mg / L, TP is 15mg / L, S 2- After hydrolysis and acidification, the COD is 9200mg / L, enters the UASB anaerobic reaction device, stays for 26h, the effluent COD is 4400mg / L, TN is 17mg / L, TP is 14.5mg / L, S 2- After secondary fenton oxidation, COD is 2800mg / L, TN is 17mg / L, TP is 14.5mg / L, primary contact aerobic effluent COD is 1200mg / L, TN is 10mg / L, TP The COD of the secondary contact aerobic effluent is 450mg / L, the TN is 5mg / L, and the TP is 3g / L, reaching the COD and the third-level emission standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com