Accelerant for textile dyeing, preparation method and applications thereof

A technology of textile printing and dyeing and dyeing accelerator, applied in the field of textile printing and dyeing, can solve the problems of being unable to be popularized and applied, and being too expensive, and achieve the effects of saving printing and dyeing water, reducing production costs, and reducing salt pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

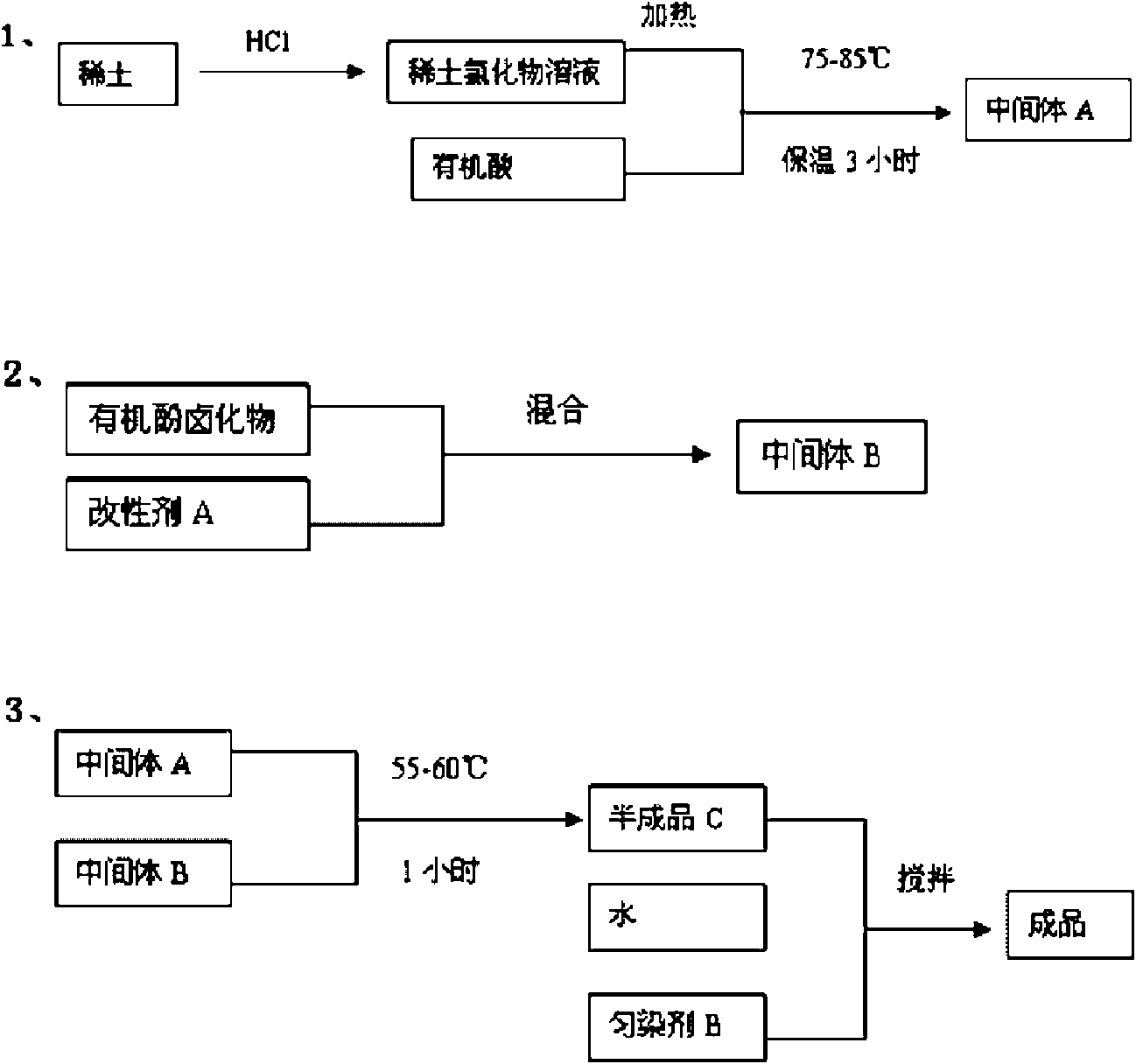

Method used

Image

Examples

Embodiment 1

[0038] (1) Use 10g of neodymium oxide and yttrium oxide with a purity of more than 99.9% as a rare earth source, dissolve them in 100ml 2mol / L hydrochloric acid to obtain a rare earth chloride solution, heat the rare earth chloride solution to 80°C, and add 50g of A 5% aqueous solution of the mixture of diethylenetriaminepentaacetic acid (DTPA) was incubated at 80°C for 3 hours to generate a rare earth organic acid complex;

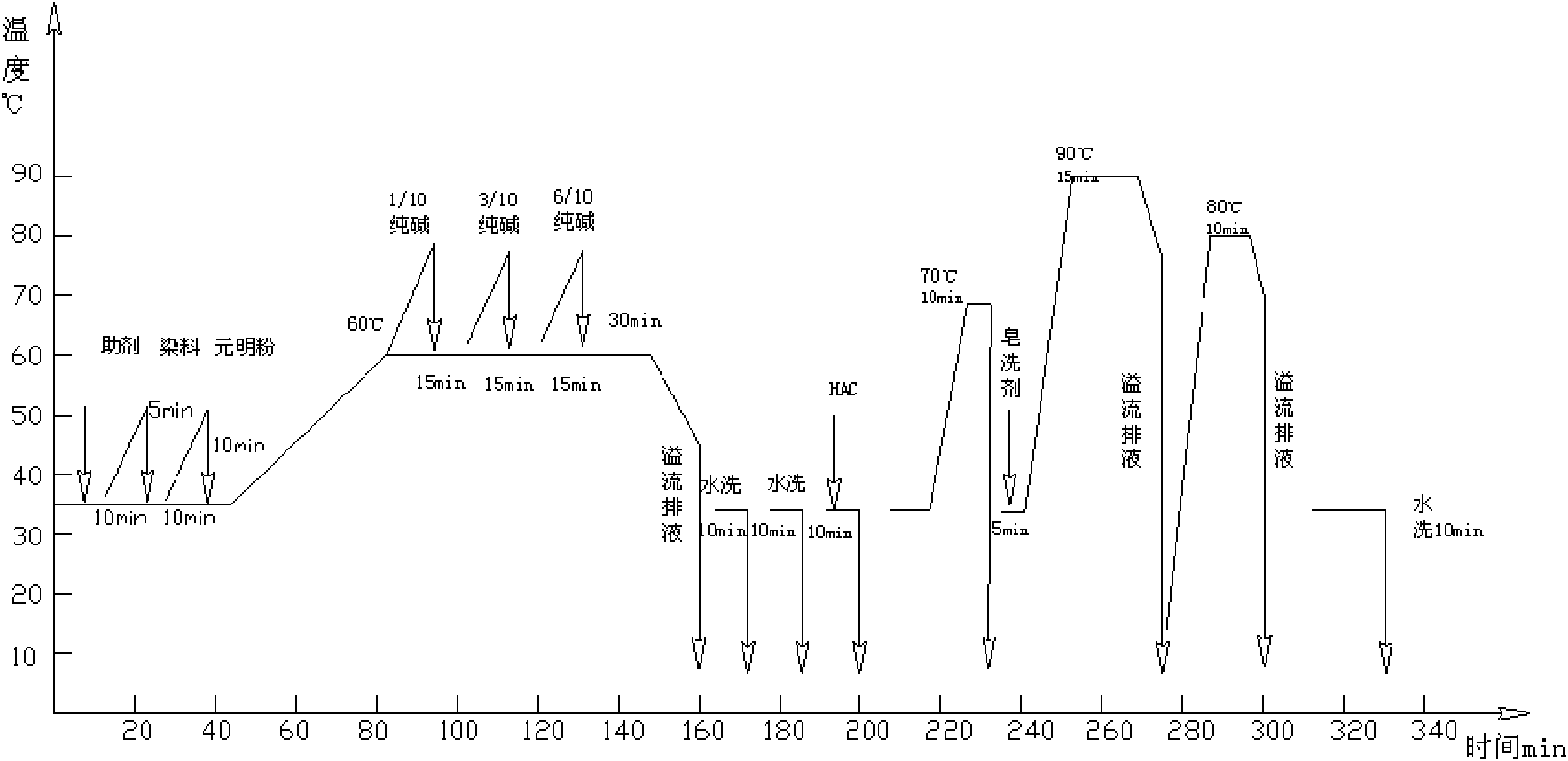

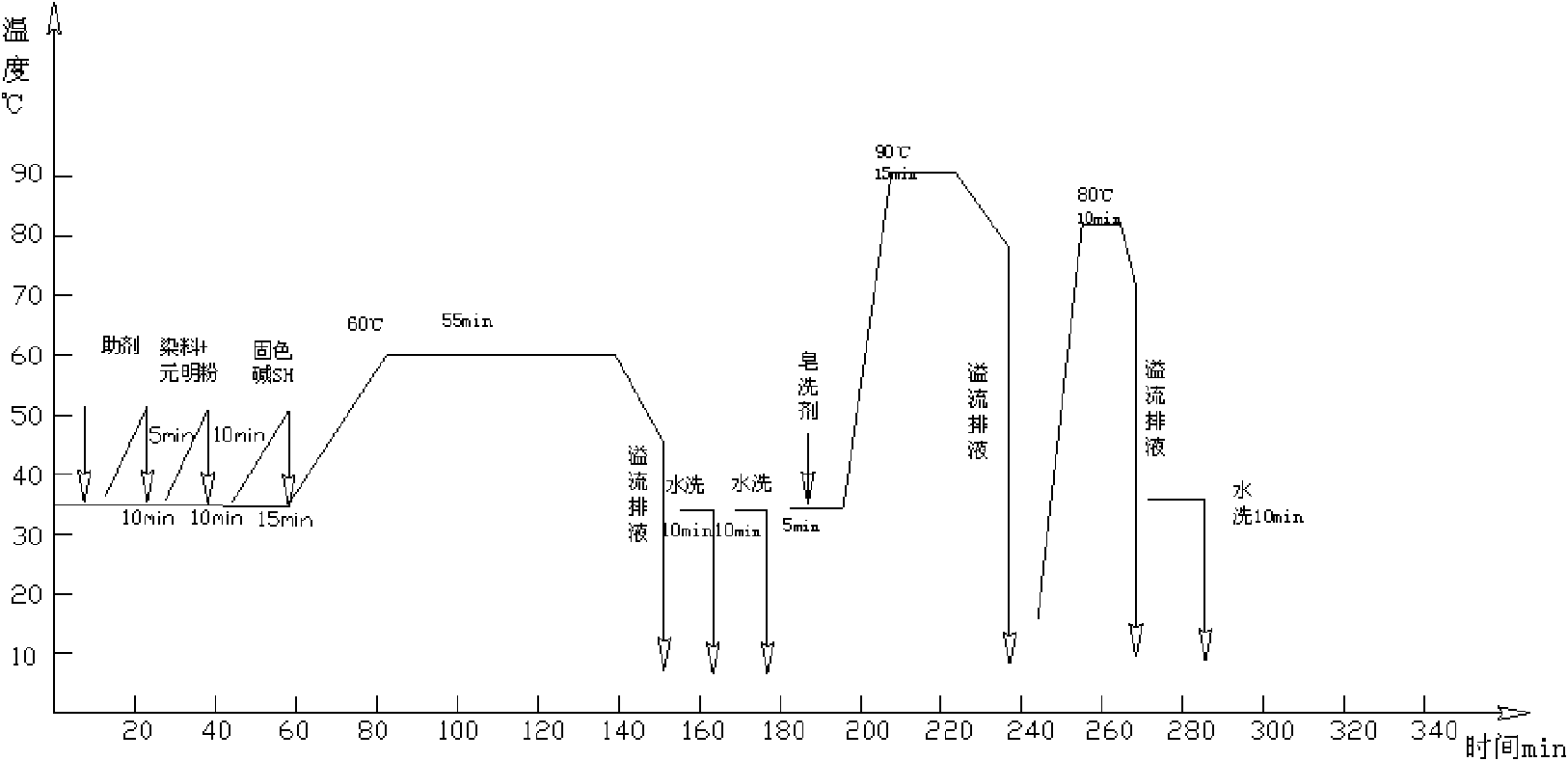

[0039] (2) Fully mix 15g of 2,4,6-trichlorophenol with 1g of modifier A (non-ionic fluorocarbon surfactant, produced by Dow Chemical Company), and add the reacted rare earth organic acid in step (1) In the complex, after reacting at 60°C for 1 hour, add a small amount of 2g of leveling agent B (styrene phenol polyoxyethylene ether ammonium sulfate), and add distilled water to 500ml, stir thoroughly for 30min and then discharge. That is the final product liquid environmental dyeing accelerator - dyeing accelerator XK08A. Its fastness index and quality ind...

Embodiment 2

[0041] Replace the rare earth source neodymium oxide and yttrium oxide in Example 1 with mixed rare earth oxides (purity > 85%), and replace the complexing agent with citric acid (CA). Agent-accelerator XK08B. Its fastness index and quality index are shown in Table 1.

Embodiment 3

[0043] The rare earth source neodymium oxide and yttrium oxide in Example 1 were replaced with yttrium chloride and selenium chloride, and the complexing agent was replaced with fumaric acid. Other operations were the same as in Example 1, and the required dyeing accelerator was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com