Fabric pressing mechanism and method

A technology of pressing roller and sliding device, applied in the field of textile printing and dyeing, can solve the problems of fabric affecting printing and dyeing quality, etc., and achieve the effect of guaranteeing effect, improving quality and preventing wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

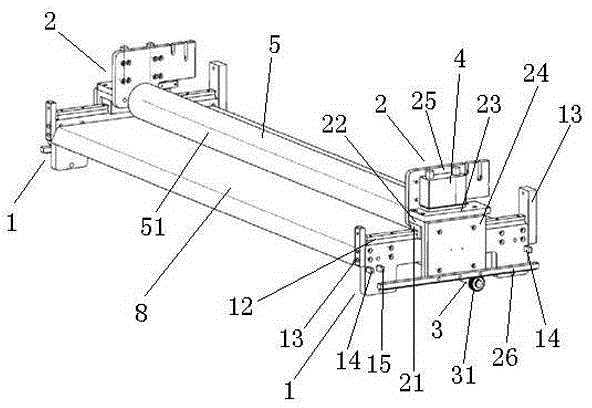

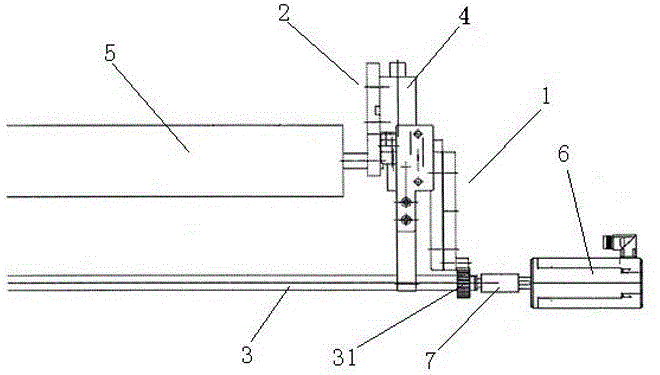

[0027] Such as figure 1 , 2 Shown as the best embodiment of the present invention, this embodiment specifically discloses a cloth pressing mechanism, which includes two symmetrically arranged supporting devices 1, two symmetrically arranged sliding devices 2 and a transmission shaft 3 that drives the two sliding devices 2. The sliding device 2 is slidably mounted on the supporting device 1; the two sliding devices 2 are respectively symmetrically installed with air cylinders 4, and a pressure roller 5 is installed between the two sliding devices 2, and the pressure roller 5 is driven by the air cylinder 4 Displacement up and down; a support plate 6 is fixedly installed between the two supporting devices 1, and the support plate 6 is located between the drive shaft 3 and the pressure roller 5.

[0028] Further, the supporting device 1 includes a fixed plate 11, a guide rail 12 is installed on the upper edge of the fixed plate 11, two baffles 13 are provided on both sides of the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com