Valve drive device

一种阀驱动、阀座的技术,应用在阀装置、阀的操作/释放装置、多通阀等方向,能够解决耗费成本、表面硬度低、高精度的面歪斜等问题,达到抑制制造成本、高面精度、制造成本的增大抑制的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] An example of a valve driving device for a refrigerator to which the present invention is applied will be described with reference to the drawings.

[0034] [all composition]

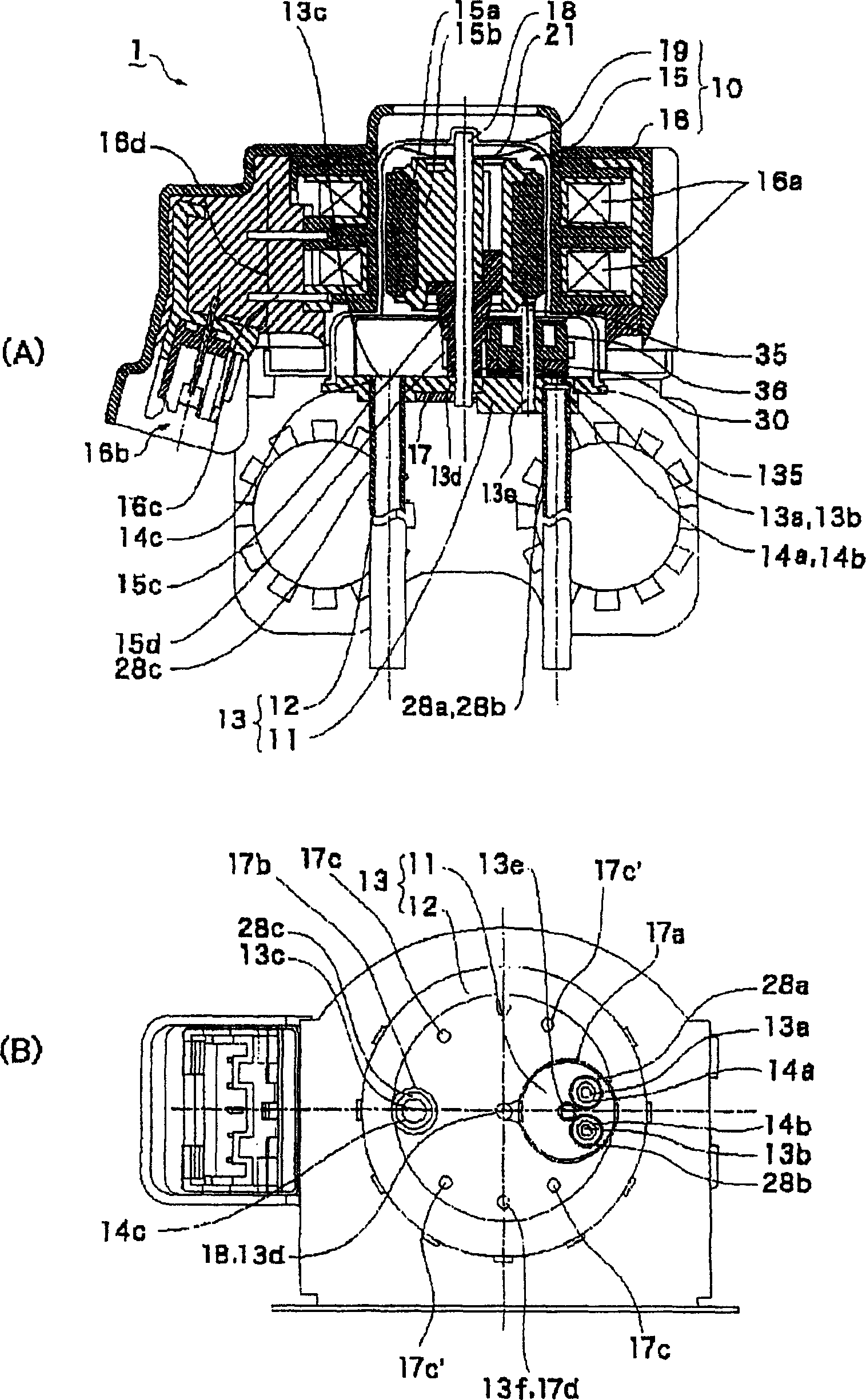

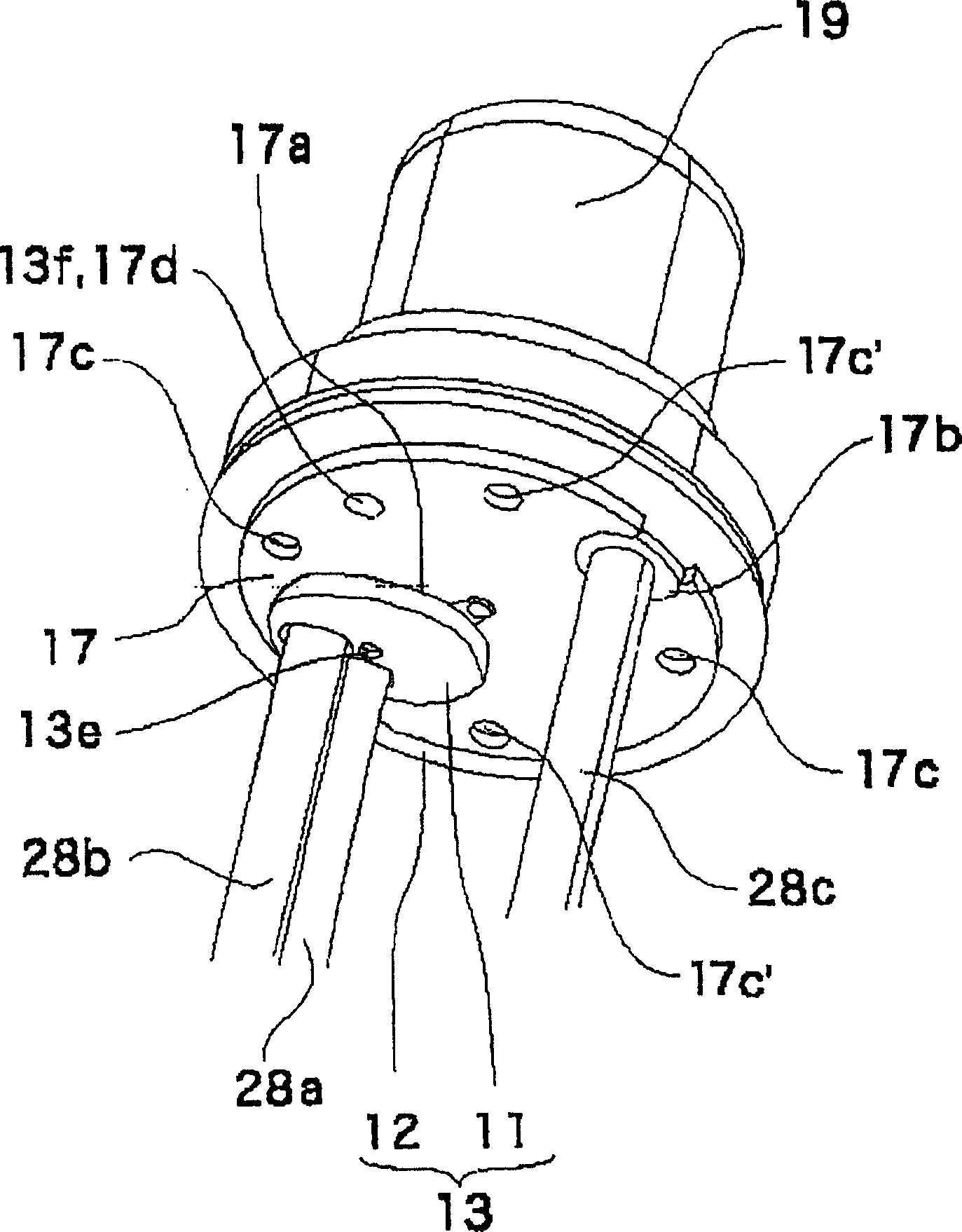

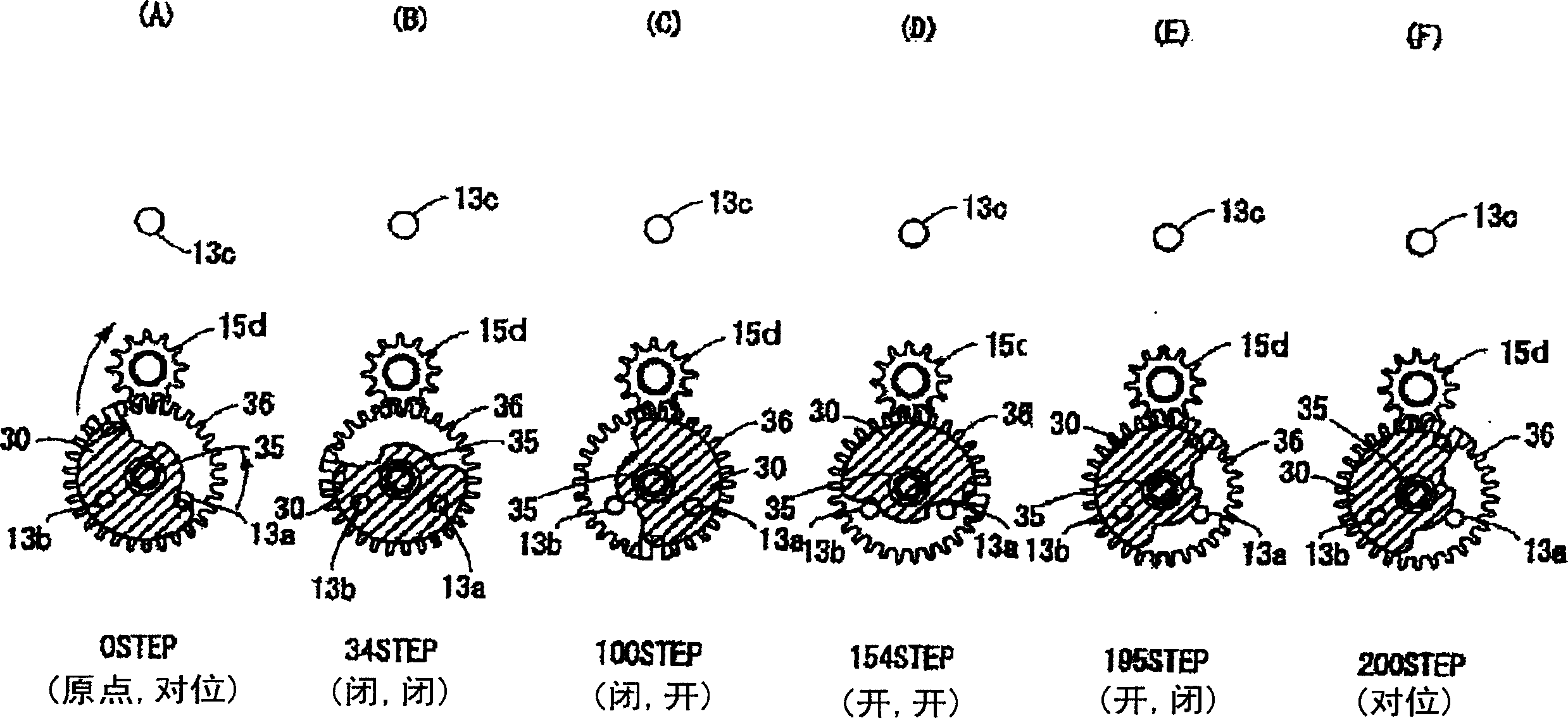

[0035] figure 1 (A), figure 1 (B) are a vertical sectional view and a bottom view of a valve driving device to which the present invention is applied, respectively. figure 2 It is a perspective view of a state in which the casing is sealed on the surface side cover of the valve seat plate as viewed obliquely from below. image 3 (A)~ image 3 (F) are figure 1 Explanatory diagrams for each mode of the valve actuator shown.

[0036] exist figure 1 Among them, the valve driving device 1 of the present embodiment includes a valve seat plate 13 and an airtight case 19 covered on the surface side of the valve seat plate 13 .

[0037] In this valve driving device 1 , a stepping motor 10 serving as a valve driving device that drives a valve body 30 is configured inside and outside a sealed case...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com