Contamination-proof detergent washing agent for textile dyeing printing process

A technology for anti-staining and textiles, applied in textiles and papermaking, dyeing, dry-cleaning fiber products, etc., can solve the problems of low dye affinity, insufficient force, poor anti-staining effect, etc., to achieve enhanced washing effect, Effect of preventing re-staining and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The composition of the anti-contamination cleaning agent for textile dyeing and printing is as follows in parts by weight:

[0026] N-Vinylpyrrolidone / Acrylamide / Vinyl Alcohol Terpolymer 5%

[0027] Maleic / Acrylic Copolymer 8%

[0028] Aliphatic amine polyoxyethylene ether 1815 6%

[0029] Fatty alcohol polyoxyethylene ether AEO9 10%

[0030] the rest is water

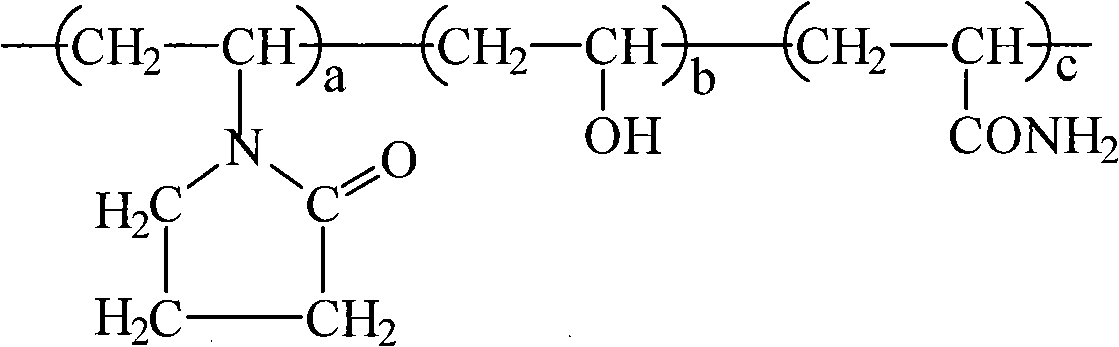

[0031] The N-vinylpyrrolidone / acrylamide / vinyl alcohol terpolymer structural formula used is:

[0032]

[0033] Among them, a: b: c is 5: 1: 2, and the molecular weight is 40000; the maleic acid / acrylic acid copolymer used is a conventional industrial product with a molecular weight of 1200; the used fatty alcohol polyoxyethylene ether AEO9, fatty amine polyoxyethylene Ether 1815 is a conventional industrial product.

Embodiment 2

[0035] The composition of the anti-contamination cleaning agent for textile dyeing and printing is as follows in parts by weight:

[0036] N-Vinylpyrrolidone / Acrylamide / Vinyl Alcohol Terpolymer 8%

[0037] Maleic / acrylic acid copolymer 3%

[0038] Sodium Polyacrylate 5%

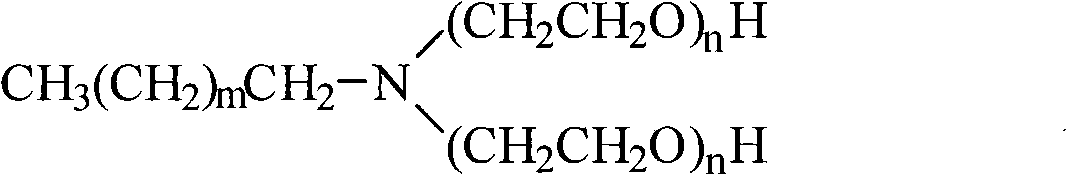

[0039] Aliphatic amine polyoxyethylene ether T15 5%

[0040] Isomerized tridecanol polyoxyethylene ether MO-7 8%

[0041] the rest is water

[0042] The N-vinylpyrrolidone / acrylamide / vinyl alcohol terpolymer structural formula used is:

[0043]

[0044] Wherein, a: b: c is 4: 2: 1, and the molecular weight is 33000; The maleic acid / acrylic acid copolymer used is a conventional industrial product with a molecular weight of 1500; the sodium polyacrylate used is a conventional industrial product with a molecular weight of 800; Isomerized tridecyl alcohol polyoxyethylene ether MO-7 and aliphatic amine polyoxyethylene ether T15 are conventional industrial products.

Embodiment 3

[0046] The composition of the anti-contamination cleaning agent for textile dyeing and printing is as follows in parts by weight:

[0047] N-Vinylpyrrolidone / Acrylamide / Vinyl Alcohol Terpolymer 3%

[0048] Maleic / Acrylic Copolymer 10%

[0049] Aliphatic amine polyoxyethylene ether 1820 8%

[0050]Isomerized tridecanol polyoxyethylene ether MO-9 8%

[0051] the rest is water

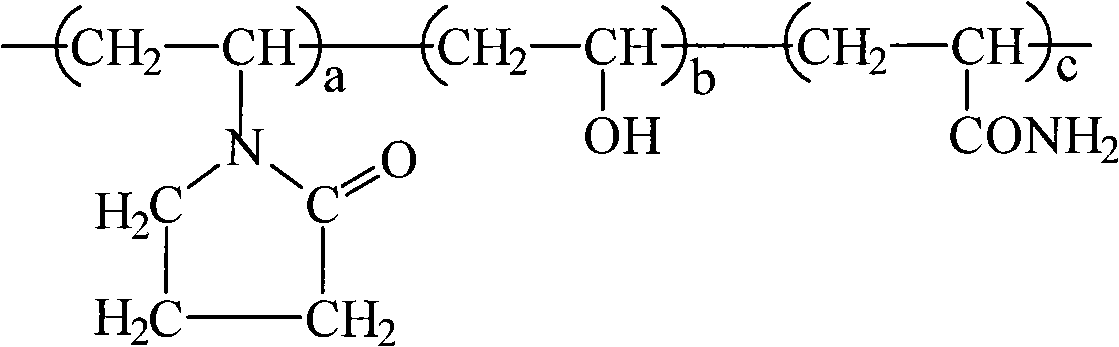

[0052] The N-vinylpyrrolidone / acrylamide / vinyl alcohol terpolymer structural formula used is:

[0053]

[0054] Wherein, a: b: c is 8: 1: 2, and the molecular weight is 63000; the maleic acid / acrylic acid copolymer used is a conventional industrial product with a molecular weight of 1800; the isomerized tridecanol polyoxyethylene ether MO-9, Fatty amine polyoxyethylene ether 1820 is a conventional industrial product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com