Wastewater treatment technology for textile dyeing and finishing industry

A technology of industrial wastewater and treatment process, applied in textile industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of high cost, easy damage, high power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

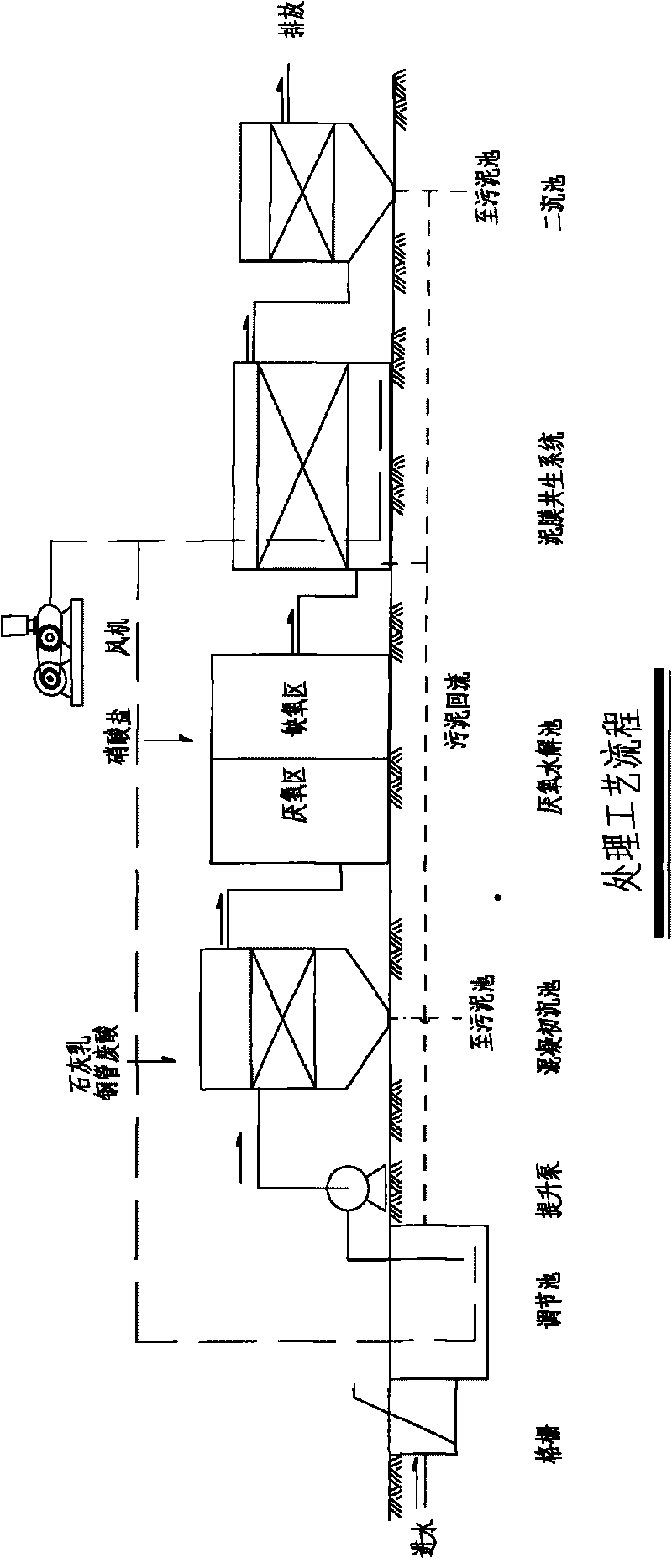

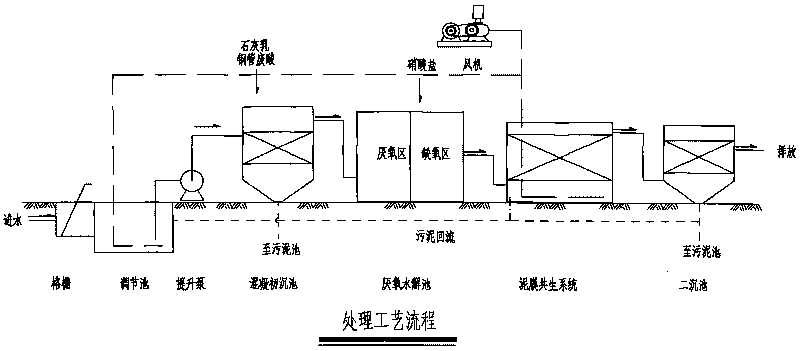

Method used

Image

Examples

Embodiment 1

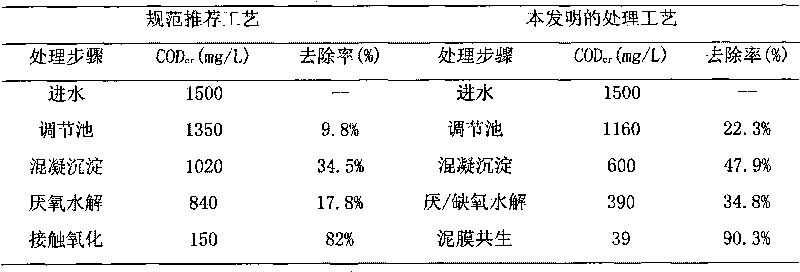

[0051] In order to verify a kind of textile dyeing and finishing industrial wastewater treatment process of the present invention, the wastewater treatment station of Changshu Lianyi Printing and Dyeing Co., Ltd. uses the treatment process of the present invention and the recommended process in "Technical Specifications for Textile Dyeing and Finishing Industrial Wastewater Treatment Engineering" HJ471-2009 processed separately. The standard recommended process is adjustment - coagulation sedimentation - anaerobic hydrolysis - contact oxidation - secondary sedimentation. The effluent water quality of each step of the two treatment processes is shown in Table 1 below.

[0052] Traditional treatment process, final effluent COD cr It is 150mg / L. And the treatment process of the present invention finally effluent COD cr It is 39mg / L, reaching the DB32 / 1072-2007 emission standard.

[0053] Table 1, Changshu Lianyi Printing and Dyeing Co., Ltd. adopts standard recommended proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com