Method for preparing cationic water-based pigment colour paste

A water-based pigment paste, cationic technology, applied in the direction of pigment paste, dyeing method, dyeing polymer organic compound treatment, etc., to achieve the effect of small particle size, high dispersion stability and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 2 grams of polystyrene-maleic anhydride copolymer (GPC measures its number average molecular weight to 19000) and 100 grams of acetone in a three-necked flask, stir with a stirrer for 15 minutes, after the copolymer is completely dissolved, add 10 grams of azo Pigment C.I. Pigment Yellow 14 was dispersed and ground on a bead mill for 2 hours. The dispersed suspension is spray-dried by a spray dryer, and with the evaporation of the solvent, the copolymer is gradually coated on the surface of the pigment to obtain a pigment powder.

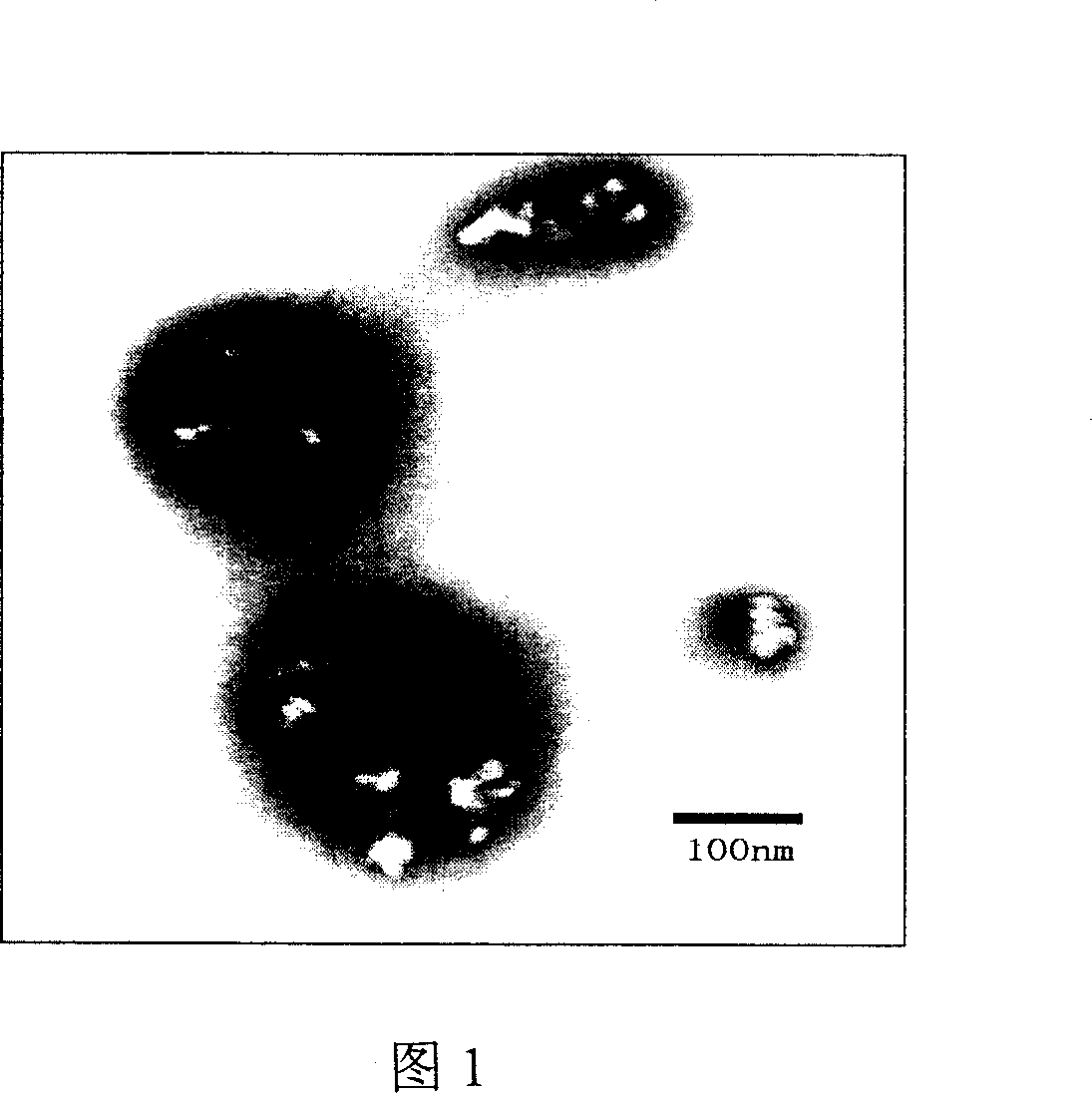

[0021] Take 10 grams of the above-mentioned pigment powder, disperse it in 50 grams of methanol-water mixed solution, add 10 grams of glycidyltrimethylammonium chloride, stir and react at 60°C for 5 hours, and distill methanol to obtain cationic water-based pigment. Add 5 grams of cationic water-based pigments to 95 grams of water, and disperse them ultrasonically for 10 minutes to obtain cationic C.I. Pigment Yellow 14 Pigment Dispersio...

Embodiment 2

[0023] Add 50 gram phthalocyanine pigments C.I. pigment blue 15: 2 and 250 gram water in there-necked flask, add the aqueous solution of 30% polyacrylic acid-methyl methacrylate copolymer (GPC measures its number average molecular weight 12000) under stirring 10 grams, it was dispersed on the high-speed emulsifier for 30 minutes, and then 10 grams of 30% polyvinylpyrrolidone aqueous solution was added, and the dispersion was continued for 2 hours. Then, slowly add 500 grams of acetone under stirring, and continue stirring for 30 minutes. The mixed solution was centrifuged, and the solvent in the upper layer after centrifugation was removed, and the modified pigment was vacuum-dried at 40°C for 24 hours to obtain a pigment powder.

[0024] Take 10 grams of the prepared pigment powder, disperse it in 50 grams of isopropanol, add 2 grams of glycidyltriethylammonium chloride, stir and react at 80°C for 4 hours, distill the isopropanol to obtain the cationic water-based paint. Ad...

Embodiment 3

[0026] Add 927.5 grams of tetrahydrofuran and 22.5 grams of polyvinyl alcohol (GPC measures its number average molecular weight 8000) in the three-necked flask, stir on the stirrer for 30 minutes, after the polymer is completely dissolved, add 50 grams of quinazetinone pigment C.I. Pigment Red 122 was dispersed on a micro jet pulverizer for 2 hours. Under the condition of full stirring, slowly add the mixture of 500 g of cyclohexane and petroleum ether, so that the polymer is deposited on the surface of the pigment. The mixture was separated by filtration, the solvent was removed, and it was freeze-dried at -15°C for 24 hours to obtain a pigment powder.

[0027] Take 10 grams of the prepared pigment powder, disperse it in 50 grams of ethanol, add 5 grams of 3-chloro-2-hydroxypropyltrimethylammonium chloride, stir and react at 80°C for 3 hours, and distill the ethanol to obtain Cationic water-based pigments. Add 5 grams of cationic water-based pigments to 95 grams of water, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com