Low-temperature scouring and bleaching one-bath-process pretreatment process of cotton knitted fabrics

A cotton knitted fabric and pre-treatment technology, which is applied in fiber treatment, biochemical fiber treatment, bleaching products, etc., can solve the problems of unavailable, long process flow, and energy consumption reduction, so as to reduce the overall cost, shorten the process flow, and better The effect of whiteness and capillary effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] For light bright color cloth (cotton 21 S Single jersey), utilize the first kind of cotton knitted fabric low-temperature scouring and bleaching one-bath pretreatment process to carry out pretreatment, the steps are as follows:

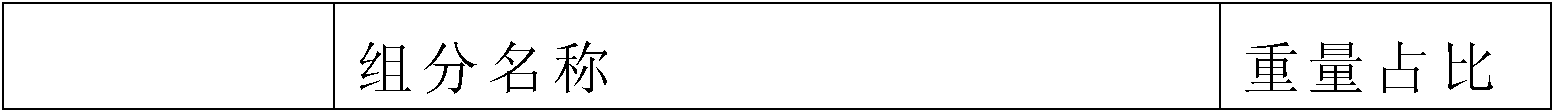

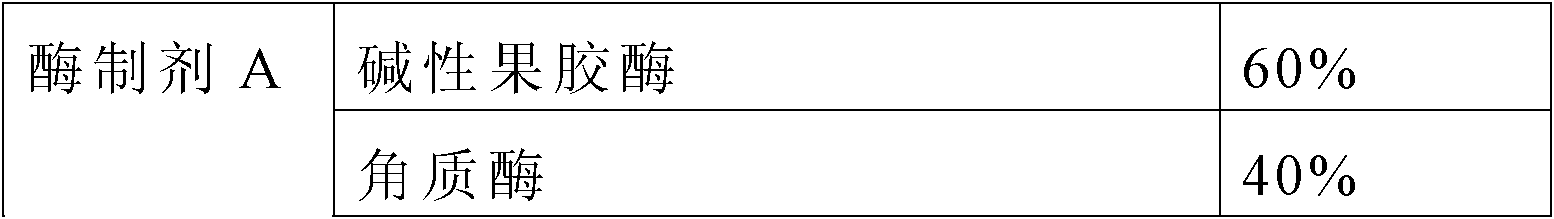

[0042] (1) Adding 0.4g scouring enzyme preparation A1, 1.6g auxiliary agent B1, 8g mass concentration of 30% hydrogen peroxide and 1g penetrating agent to prepare scouring and bleaching solution according to the ratio of per liter of water;

[0043] (2) Place the cotton knitted fabric to be treated in the scouring and bleaching solution at 60°C for scouring and bleaching, and keep for 60 minutes, the bath ratio of the cotton knitted fabric and the scouring and bleaching solution is 1:8;

[0044] (3) drain the scouring and bleaching solution, and wash the cotton knitted fabric after scouring and bleaching;

[0045] (4) The washed cotton knitted fabric is deoxidized by deoxygenase for dyeing.

[0046] The whiteness of the cotton knitted fabric ...

Embodiment 2

[0048] For light bright color cloth (cotton 21 S Single jersey), utilize the first kind of cotton knitted fabric low-temperature scouring and bleaching one-bath pretreatment process to carry out pretreatment, the steps are as follows:

[0049] (1) Adding 0.8g scouring enzyme preparation A2, 1g auxiliary agent B2, 7g mass concentration as 30% hydrogen peroxide and 1g penetrating agent to prepare scouring and bleaching solution in every liter of water;

[0050] (2) Putting the cotton knitted fabric to be treated into the scouring and bleaching solution at 70° C. for scouring and bleaching for 30 minutes, the bath ratio of the cotton knitted fabric and the scouring and bleaching solution is 1:10;

[0051] (3) drain the scouring and bleaching solution, and wash the cotton knitted fabric after scouring and bleaching;

[0052] (4) After washing, the cotton knitted fabric is deoxidized by deoxygenase to prepare for dyeing;

[0053] The whiteness of the cotton knitted fabric treated...

Embodiment 3

[0055] For light bright color cloth (cotton 21 S Single jersey), utilize the first kind of cotton knitted fabric low-temperature scouring and bleaching one-bath pretreatment process to carry out pretreatment, the steps are as follows:

[0056] (1) Adding 0.2g scouring enzyme preparation A3, 0.8g auxiliary agent B3, 4g mass concentration as 30% hydrogen peroxide and 1g osmotic agent in every liter of water to prepare scouring and bleaching solution;

[0057] (2) Putting the cotton knitted fabric to be treated into the scouring and bleaching solution at 50° C. for scouring and bleaching, keeping for 50 minutes, the bath ratio of the cotton knitted fabric and the scouring and bleaching solution is 1:6;

[0058] (3) drain the scouring and bleaching solution, and wash the cotton knitted fabric after scouring and bleaching;

[0059] (4) After washing, the cotton knitted fabric is deoxidized by deoxygenase to prepare for dyeing;

[0060]The whiteness of the cotton knitted fabric tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gross effect | aaaaa | aaaaa |

| Gross effect | aaaaa | aaaaa |

| Gross effect | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com