Sliding cool fiber and preparation and application thereof

A cool fiber and slippery technology, applied in fiber processing, textiles and papermaking, conjugated synthetic polymer artificial filaments, etc., can solve the problems of inability to directly compound composite fiber filaments and great differences in polyamide properties, and achieve the goal of rejecting Excellent water properties, soft touch, high melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

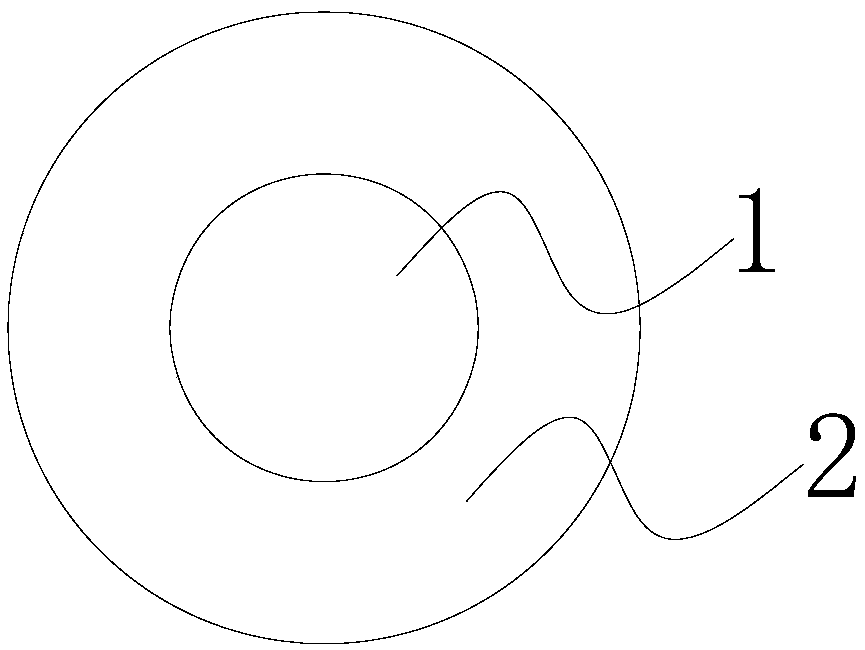

Image

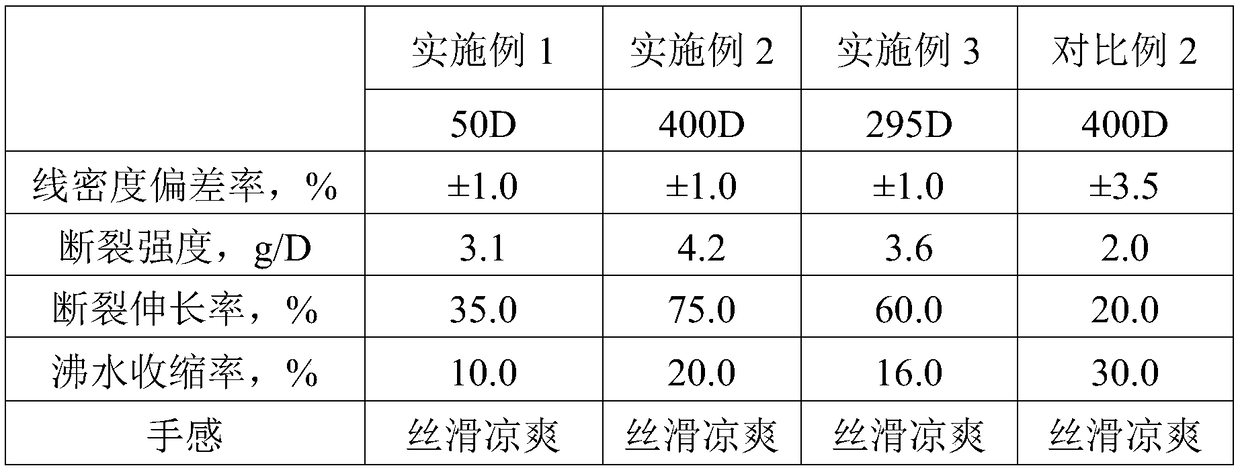

Examples

Embodiment 1

[0038]Composite spinning process is adopted, the heat medium of PA6 melt is biphenyl, the heat medium of HDPE melt is aromatic hydrocarbon (Youre 209, manufacturer: Suzhou Kaimei Chemical Industry), and there are two melt distribution pipes in the spinning box : PA melt distribution pipe and PE melt distribution pipe, the length of the PE melt distribution pipe is 30% shorter than the length of the PA melt distribution pipe, and the spinning assembly in the spinning box is a skin-core composite spinning assembly, Spinnerets with concentric sheath-core structure.

[0039] With 30Kg PA6 (fiber-grade filament PA6 chips, Wuxi Changan Polymer Material Co., Ltd.) as the core material, 70Kg HDPE (fiber-grade HDPE chips, China Petroleum and Natural Gas Co., Ltd.) The first screw extruder is melted and extruded to obtain PA6 melt, HDPE is melted and extruded by the second screw extruder with a screw temperature of 180°C to obtain HDPE melt; PA6 melt passes through PA melt distribution ...

Embodiment 2

[0042] Composite spinning process is adopted, the heat medium of PA6 melt is biphenyl, the heat medium of HDPE melt is aromatic hydrocarbon (Youre 209, manufacturer: Suzhou Kaimei Chemical Industry), and there are two melt distribution pipes in the spinning box : PA melt distribution pipe and PE melt distribution pipe, the length of the PE melt distribution pipe is 40% shorter than the length of the PA melt distribution pipe, and the spinning assembly in the spinning box is a skin-core composite spinning assembly, Spinnerets with concentric sheath-core structure.

[0043] With 50Kg PA6 (fiber-grade filament PA6 chips, produced by Wuxi Changan Polymer Material Co., Ltd.) as the core material, 50Kg HDPE (fiber-grade HDPE chips, produced by China Petroleum and Natural Gas Co., Ltd.) as the skin material, the temperature of PA6 through the screw is The first screw extruder at 270°C is melted and extruded to obtain PA6 melt, HDPE is melted and extruded by the second screw extruder ...

Embodiment 3

[0046] Composite spinning process is adopted, the heat medium of PA6 melt is biphenyl, the heat medium of HDPE melt is aromatic hydrocarbon (Youre 209, manufacturer: Suzhou Kaimei Chemical Industry), and there are two melt distribution pipes in the spinning box : PA melt distribution pipe and PE melt distribution pipe, the length of the PE melt distribution pipe is 35% shorter than the length of the PA melt distribution pipe, and the spinning assembly in the spinning box is a skin-core composite spinning assembly, Spinnerets with concentric sheath-core structure.

[0047] 70Kg PA6 (fiber-grade filament PA6 chips, produced by Wuxi Changan Polymer Material Co., Ltd.) is used as the core material, 30Kg HDPE (fiber-grade HDPE chips, produced by China Petroleum and Natural Gas Co., Ltd.) is used as the skin material, and the temperature of PA6 through the screw is 250 The first screw extruder at ℃ is melted and extruded to obtain PA6 melt, and HDPE is melted and extruded by the sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com