Finishing method using anti-ultraviolet finishing agent

An anti-ultraviolet and finishing agent technology, applied in fiber processing, textiles and papermaking, etc., can solve the problems of short UVB wavelength and increase melanoma, and achieve the effect of short process, simple process and cool touch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

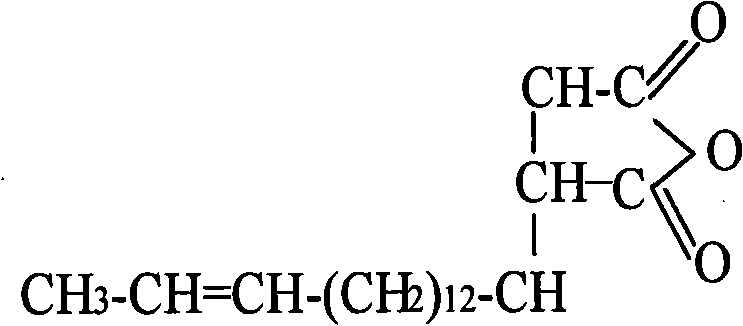

Method used

Image

Examples

Embodiment 1

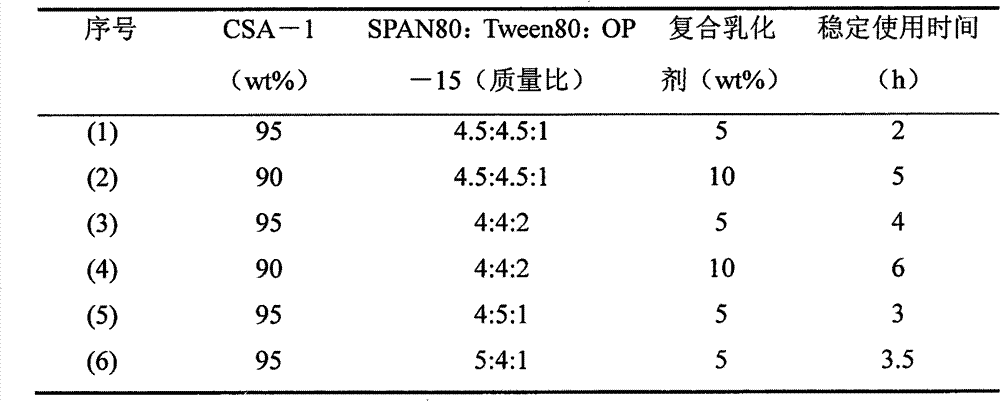

[0025] Compound emulsifiers were prepared with different ratios of SPAN80: Tween80: OP-15, and emulsions with different concentrations of CSA-1 were prepared. The results are shown in Table 1;

[0026] Table 1

[0027]

[0028] As can be seen from Table 1, the CSA-1 emulsions prepared by the 6 formulations in Table 1 can meet the requirements of ready-to-use, and the emulsions prepared by (5), (3), and (4) have a relatively long stable time.

Embodiment 2

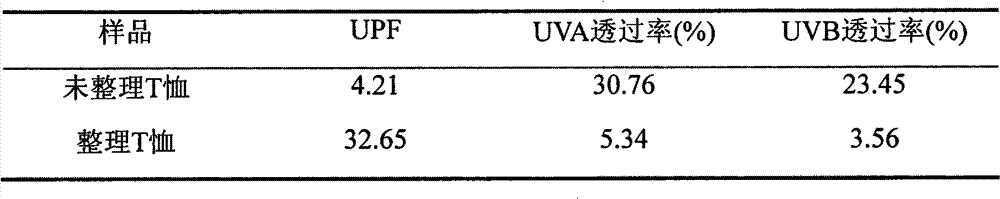

[0030] Prepare finishing liquid: CSA-1 emulsion ((1) formula in embodiment 1) 3.5% (the quality of CSA-1 is to the quality of T-shirt), ammonium sulfate 10% (to the quality of CSA-1 emulsion), add Nano Zinc Oxide 1.5% (relative to the quality of the T-shirt), the rest is water. Soak the T-shirt → raise the temperature to 60°C, keep it warm for 30 minutes → spin dry → dry. Determination of UPF value, UVA transmittance, UVB transmittance, as shown in Table 2.

[0031] Table 2

[0032]

Embodiment 3

[0034] Prepare finishing liquid: CSA-1 emulsion ((3) formula in embodiment 1) 3% (the quality of CSA-1 is to the quality of T-shirt), ammonium sulfate 10% (to the quality of CSA-1 emulsion), add Nano-titanium oxide 1.5% (relative to the quality of the T-shirt),

[0035] Make up the remaining amount of water. Soak the shirt → heat up to 60°C, keep warm for 30 minutes → spin dry → dry. Determination of UPF value, UVA transmittance, UVB transmittance, as shown in Table 3.

[0036] table 3

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com