Aluminum alloy hub surface anodic oxidation treatment process

An aluminum alloy wheel, anodic oxidation technology, applied in the direction of anodic oxidation, surface reaction electrolytic coating, electrolytic coating, etc., can solve the problems affecting the appearance and quality of the wheel hub, and achieve a good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

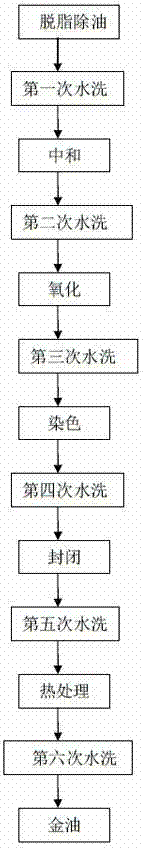

[0023] A kind of aluminum alloy wheel hub surface anodic oxidation treatment process, comprises the following steps:

[0024] Such as figure 1 As shown, firstly, the wheel hub is produced according to the normal process, after casting, machining, painting, and after painting, the front side of the car is brightened with a CNC lathe to meet the requirements of the car bright surface product.

[0025] (1) Degreasing and degreasing: Degreasing the surface of the aluminum alloy wheel, putting the aluminum alloy wheel in 8% sulfuric acid solution at room temperature, degreasing and degreasing for 5 minutes;

[0026] The first water washing: wash the surface of the hub repeatedly with tap water for 4 minutes to ensure that the PH value of the surface of the hub is greater than 5;

[0027] (2) Neutralization: Put the aluminum alloy wheel hub into a sodium hydroxide solution with a concentration of 50g / L and a temperature of 60°C, and neutralize with alkali for 5 minutes;

[0028] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com