Aluminum alloy for anodic oxidation and preparation method thereof

An anodizing and aluminum alloy technology, applied in the field of aluminum alloy, can solve the problems of poor anodizing effect, low hardness of aluminum alloy, heavy twill on the surface of aluminum alloy, etc., and achieve the effects of easy to master, simple preparation method, high strength and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

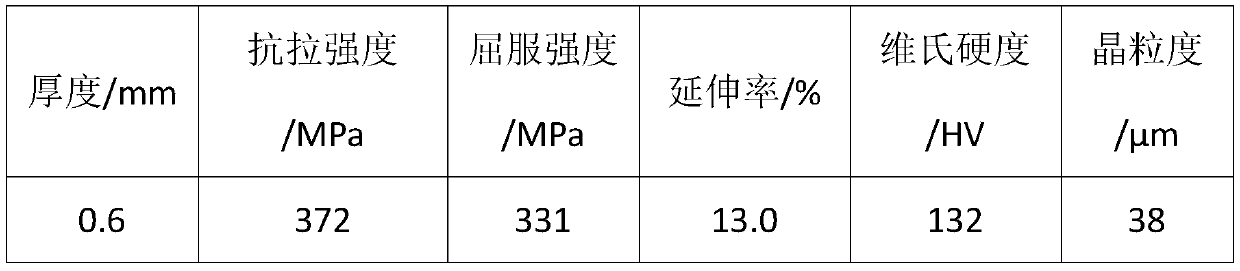

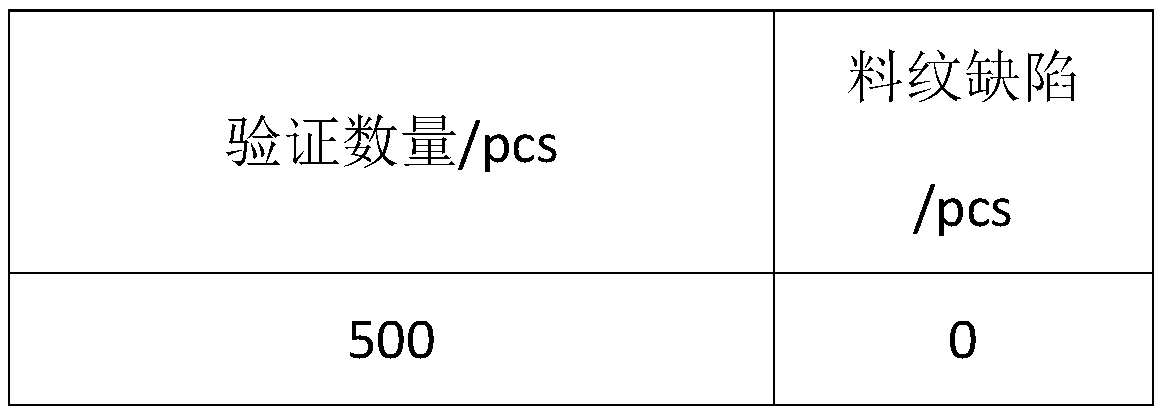

Embodiment 1

[0029] An aluminum alloy for anodic oxidation, mainly made of the following raw materials by weight percentage: Si: 0.7%, Fe: 0.07%, Cu: 0.3%, Mn: 0.08%, Mg: 1.1%, Cr: 0.02%, Zn: 0.04%, Ti: 0.03%, the balance being Al, Mg / Si=1.57.

[0030] A method for preparing aluminum alloy for anodic oxidation, comprising the following steps:

[0031] (1) Melting: Mix various raw materials according to weight percentage, heat to 740° C. to melt the mixed material, and keep warm for 3 hours.

[0032] (2) Degassing and filtering: degassing the molten aluminum, and then using a filter device to remove insoluble impurities in the aluminum melt. The hydrogen content in the aluminum melt is 0.05ml / 100gAl.

[0033] (3) Casting: pour the degassed and filtered aluminum liquid, cool it to obtain an ingot, and cast a flat ingot with a size of 520mm×1620mm×7000mm.

[0034] (4) Homogenization heat treatment: The ingot is subjected to homogenization treatment, the soaking temperature is 540° C., and t...

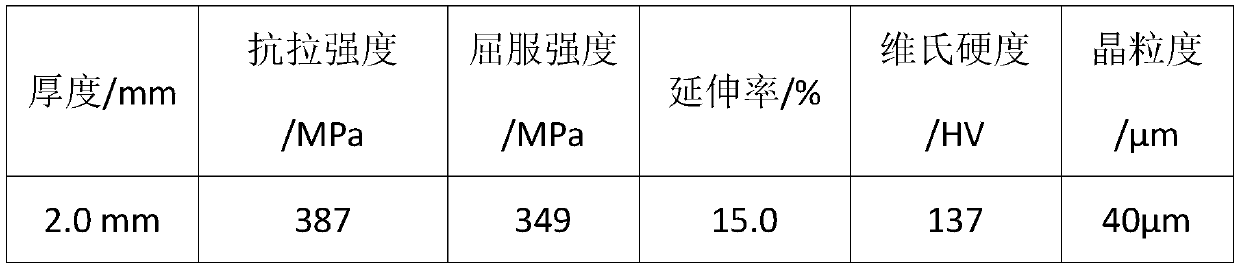

Embodiment 2

[0046] An aluminum alloy for anodic oxidation, mainly made of the following raw materials by weight percentage: Si: 0.9%, Fe: 0.1%, Cu: 0.6%, Mn: 0.15%, Mg: 1.4%, Cr: 0.03%, Zn: 0.1%, Ti: 0.1%, the balance being Al, Mg / Si=1.56.

[0047] A method for preparing aluminum alloy for anodic oxidation, comprising the following steps:

[0048] (1) Melting: Mix various raw materials according to weight percentage, heat to 750° C. to melt the mixed material, and keep warm for 5 hours.

[0049] (2) Degassing and filtering: degassing the molten aluminum, and then using a filter device to remove insoluble impurities in the aluminum melt. The hydrogen content in the aluminum melt is 0.08ml / 100gAl.

[0050] (3) Casting: pour the degassed and filtered aluminum liquid, cool it to obtain an ingot, and cast a flat ingot with a size of 520mm×1620mm×6500mm.

[0051] (4) Homogenization heat treatment: The ingot is subjected to homogenization treatment, the soaking temperature is 560° C., and the ...

Embodiment 3

[0064] An aluminum alloy for anodic oxidation, mainly made of the following raw materials by weight percentage: Si: 0.6%, Fe: 0.05%, Cu: 0.1%, Mn: 0.05%, Mg: 1.0%, Cr: 0.01%, Zn: 0.01%, Ti: 0.01%, the balance being Al, Mg / Si=1.67.

[0065] A method for preparing aluminum alloy for anodic oxidation, comprising the following steps:

[0066] (1) Melting: Mix various raw materials according to weight percentage, heat to 760° C. to melt the mixed material, and keep the temperature for 8 hours.

[0067] (2) Degassing and filtering: degassing the molten aluminum, and then using a filter device to remove insoluble impurities in the aluminum melt. The hydrogen content in the aluminum melt is 0.12ml / 100gAl.

[0068] (3) Casting: pour the degassed and filtered aluminum liquid, cool it to obtain an ingot, and cast a flat ingot with a size of 520mm×1620mm×7000mm.

[0069] (4) Homogenization heat treatment: The ingot is subjected to homogenization treatment, the soaking temperature is 580...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com