Al-Zn-Mg-Cu alloy and preparation process

A 1. al-zn-mg-cu, preparation process technology, applied in the field of aluminum alloys, can solve the problems such as the inability to continue to increase the strength, cracking and bursting, and the inability to meet the requirements of electronic structural parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This example provides Al-Zn-Mg-Cu alloy, described Al-Zn-Mg-Cu alloy comprises the preparation raw material of following mass percent:

[0052] Zn: 6.7~7.2%,

[0053] Mg: 1.7~2.2%,

[0054] Cu: 0.20~0.45%,

[0055] Mn: 0.15~0.30%,

[0056] Zr: 0.05~0.20%,

[0057] The balance is Al;

[0058] In the Al-Zn-Mg-Cu alloy, the mass ratio Zn / Mg of Zn and Mg is 3.0-4.0, and the total amount of elements of Zn and Mg is ≤9.2%.

[0059] Wherein, the total amount of elements of Mn and Zr is 0.20-0.40%.

[0060] The total elemental content of Fe and Si is ≤0.18%.

[0061] Si≤0.08%, Fe≤0.12%, Cr≤0.05%, Ti≤0.10%.

Embodiment 2

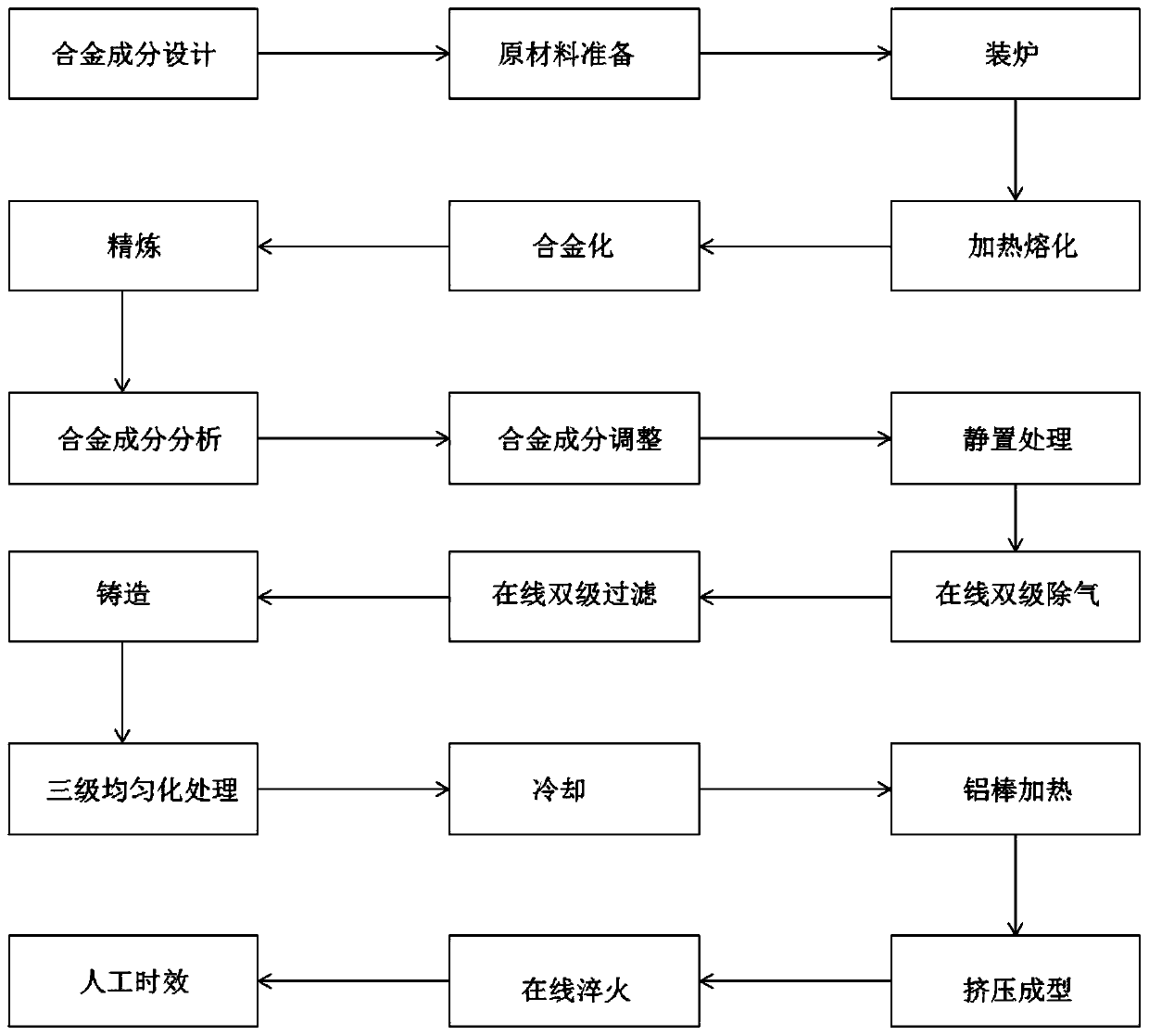

[0063] This example provides the preparation process of Al-Zn-Mg-Cu alloy, the steps include:

[0064] S1: Dosing according to the proportion, after melting the aluminum ingot, add zinc ingot and magnesium ingot to obtain an alloyed melt;

[0065] S2: adding a refining agent to the alloyed melt in step S1 for refining, and at the same time feeding argon gas from the bottom of the melt for stirring, exhausting and slagging;

[0066] S3: fine-tuning the composition of the melt refined in step S2 and then standing still;

[0067] S4: Deeply purifying the melt in step S3 and pouring it to obtain a green body;

[0068] S5: After the green body is heat-treated, the water mist is forcibly cooled to room temperature to obtain the Al-Zn-Mg-Cu alloy.

[0069] In step S1, the melting temperature of the aluminum ingot is 730-760°C.

[0070] In step S2, the refining temperature is 730-750° C., and the refining time is 35-45 minutes. The amount of refining agent added is 2kg per ton of ...

Embodiment 3

[0076] This example provides the material processing method of Al-Zn-Mg-Cu alloy, the steps include:

[0077] (1) Cut the alloy saw into short ingots with a length of 600-900 mm;

[0078] (2) Put the short cast ingot into the aluminum rod heating furnace, and heat the aluminum rod to 420-500°C, preferably 450°C;

[0079] (3) Extrude the short ingot, the extrusion speed (master cylinder forward speed) is 2.0-5.0mm / s, preferably 3.0-4.0mm / s; the extrusion ratio (extrusion coefficient λ) is 20- 60, preferably 25-40;

[0080] (4) On-line quenching, preferably achieved by the following steps: within 15s, pass through a water tank with a water temperature of 5-60°C, and the cooling rate of on-line quenching is greater than 30°C / s;

[0081] (5) Straighten the material by stretching, and remove the residual stress of the material at the same time, and the stretching amount is 1 to 3%;

[0082] (6) Artificial aging, the process conditions are: 120±5°C heat preservation for 20-40h. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com