Preparation method of aluminum alloy composite material for outer part of electronic product

A technology of composite materials and electronic products, applied in metal rolling and other directions, can solve the problems of low surface hardness, low strength, and difficulty in meeting high strength and anodic oxidation performance of 6-series aluminum alloy materials, and achieve the effect of excellent hardness and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

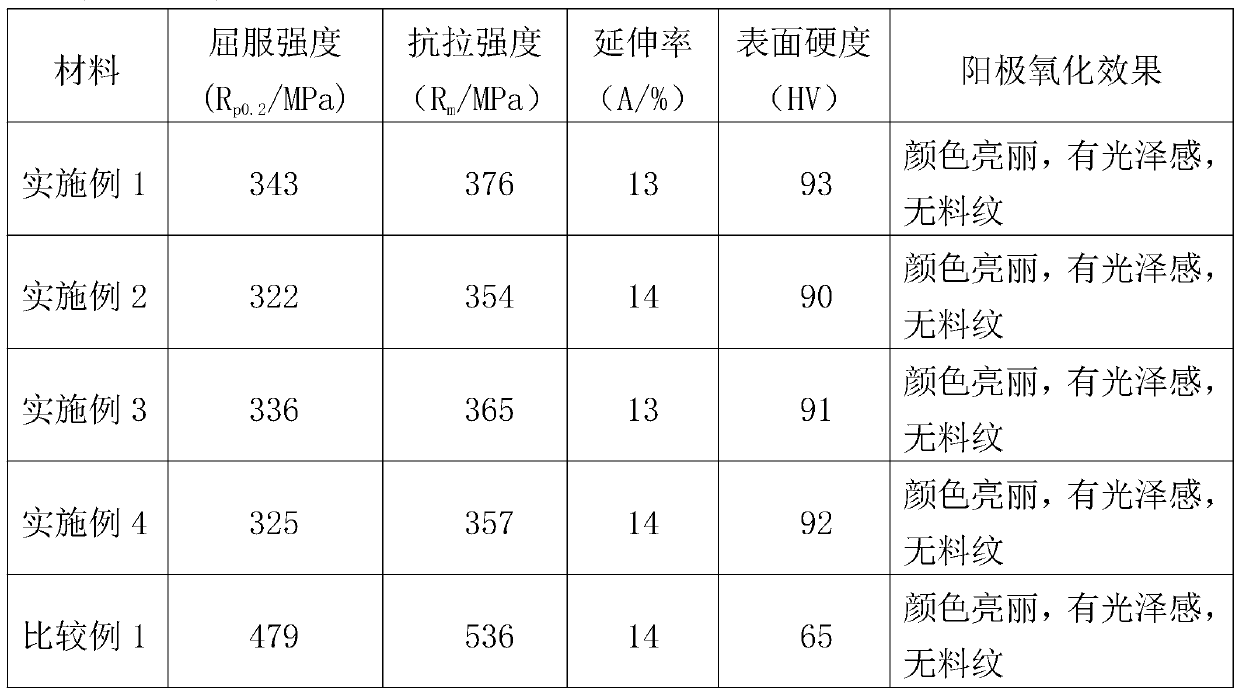

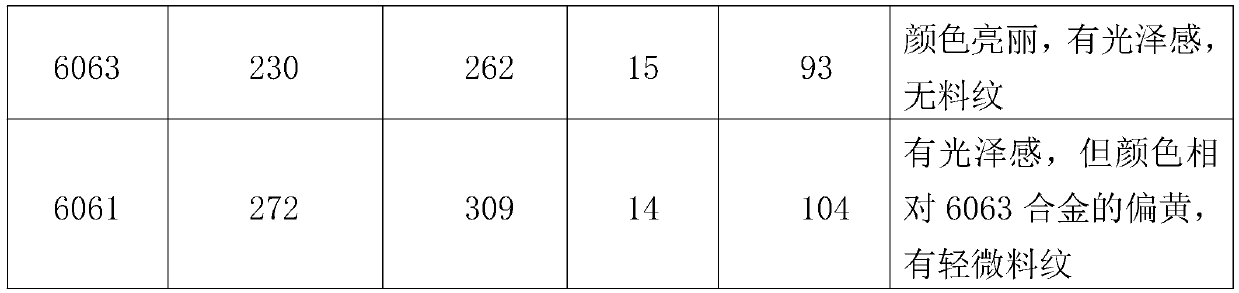

Examples

Embodiment 1

[0023] An aluminum alloy composite material for appearance parts of electronic products, comprising a core layer alloy layer and a cladding layer alloy layer, the core layer alloy is 6013 alloy, and the cladding layer alloy is 6063 alloy; the aluminum alloy composite material for the appearance part of electronic products The preparation method, the operation steps are as follows:

[0024] (1) Preparation of core layer alloy and cladding layer alloy plates: according to the designed core layer and cladding layer alloy composition, the core layer alloy ingots and ingots with a thickness of 580mm are obtained after smelting, degassing, filtering and casting. Cladding layer alloy ingots, then the core layer alloy ingots and cladding layer alloy ingots are respectively homogenized annealing, sawing, and milling to obtain a core layer alloy plate with a thickness of 275mm and a cladding layer alloy with a thickness of 31mm For the plate, the core layer alloy plate accounts for 90% of ...

Embodiment 2

[0032] An aluminum alloy composite material for appearance parts of electronic products, comprising a core layer alloy layer and a cladding layer alloy layer, the core layer alloy is 6013 alloy, and the cladding layer alloy is 6463 alloy; the aluminum alloy composite material for the appearance part of electronic products The preparation method, the operation steps are as follows:

[0033] (1) Preparation of core layer alloy and cladding layer alloy plates: according to the designed core layer and cladding layer alloy composition, the core layer alloy ingots and ingots with a thickness of 580mm are obtained after smelting, degassing, filtering and casting. Cladding layer alloy ingot, then the core layer alloy ingot and the cladding layer alloy ingot are respectively homogenized annealing, sawing and milling to obtain a core layer alloy plate with a thickness of 275mm and a cladding layer alloy with a thickness of 78mm For the plate, the core layer alloy plate accounts for 78% of ...

Embodiment 3

[0041] An aluminum alloy composite material for appearance parts of electronic products, comprising a core layer alloy layer and a cladding layer alloy layer, the core layer alloy is 6082 alloy, and the cladding layer alloy is 6063 alloy; the aluminum alloy composite material for the appearance part of electronic products The preparation method, the operation steps are as follows:

[0042] (1) Preparation of core layer alloy and cladding layer alloy plates: according to the designed core layer and cladding layer alloy composition, the core layer alloy ingots and ingots with a thickness of 580mm are obtained after smelting, degassing, filtering and casting. Cladding layer alloy ingot, then the core layer alloy ingot and the cladding layer alloy ingot are respectively homogenized annealing, sawing and milling to obtain a core layer alloy plate with a thickness of 275mm and a cladding layer alloy with a thickness of 18mm For the plate, the core layer alloy plate accounts for 94% of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com