High-melting-point heat-resisting wrought aluminum alloy and preparation method thereof

A heat-resistant deformation, aluminum alloy technology, applied in the field of alloy manufacturing, can solve problems such as high-altitude curtain wall glass falling off, potential safety hazards, aluminum alloy door and window glass cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

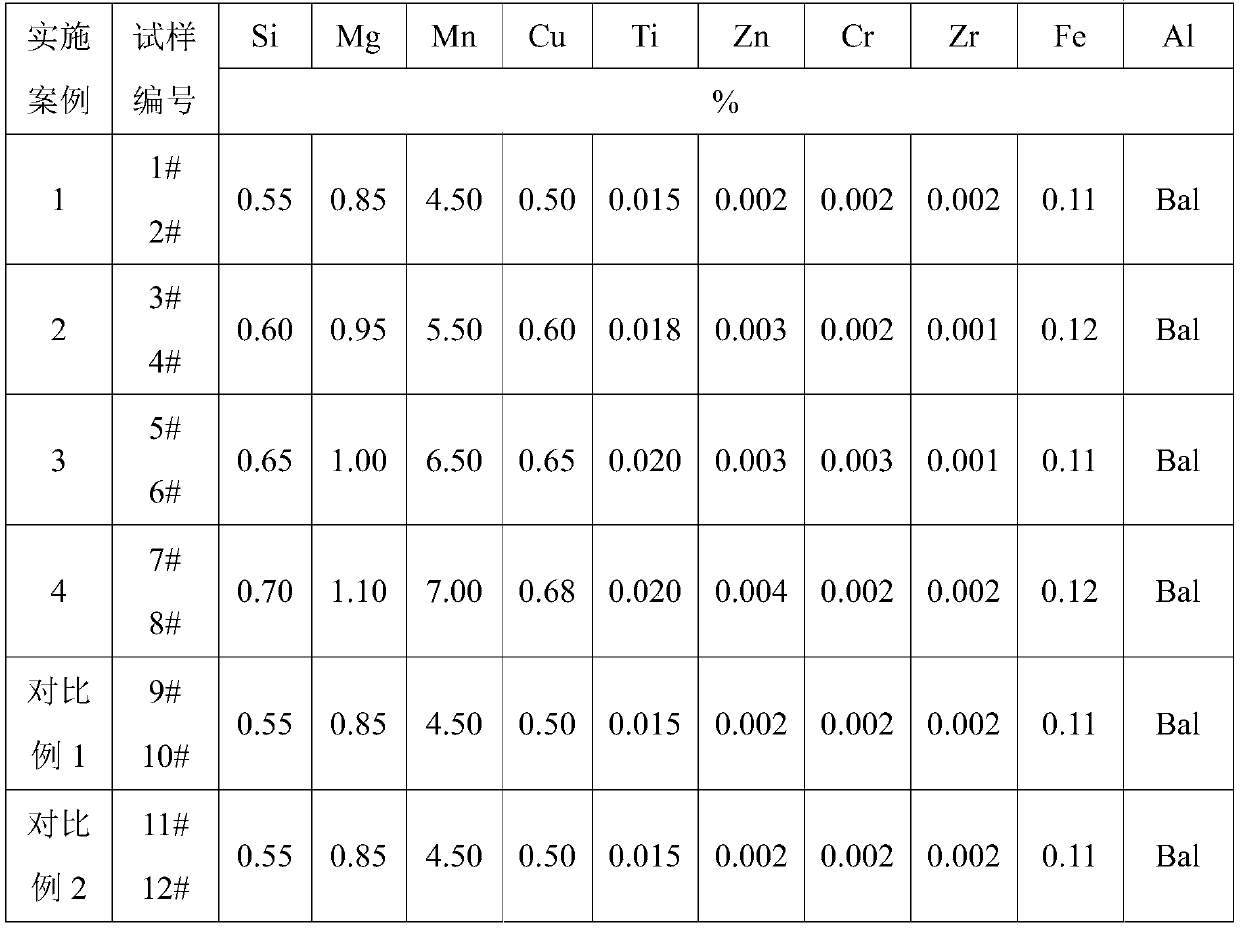

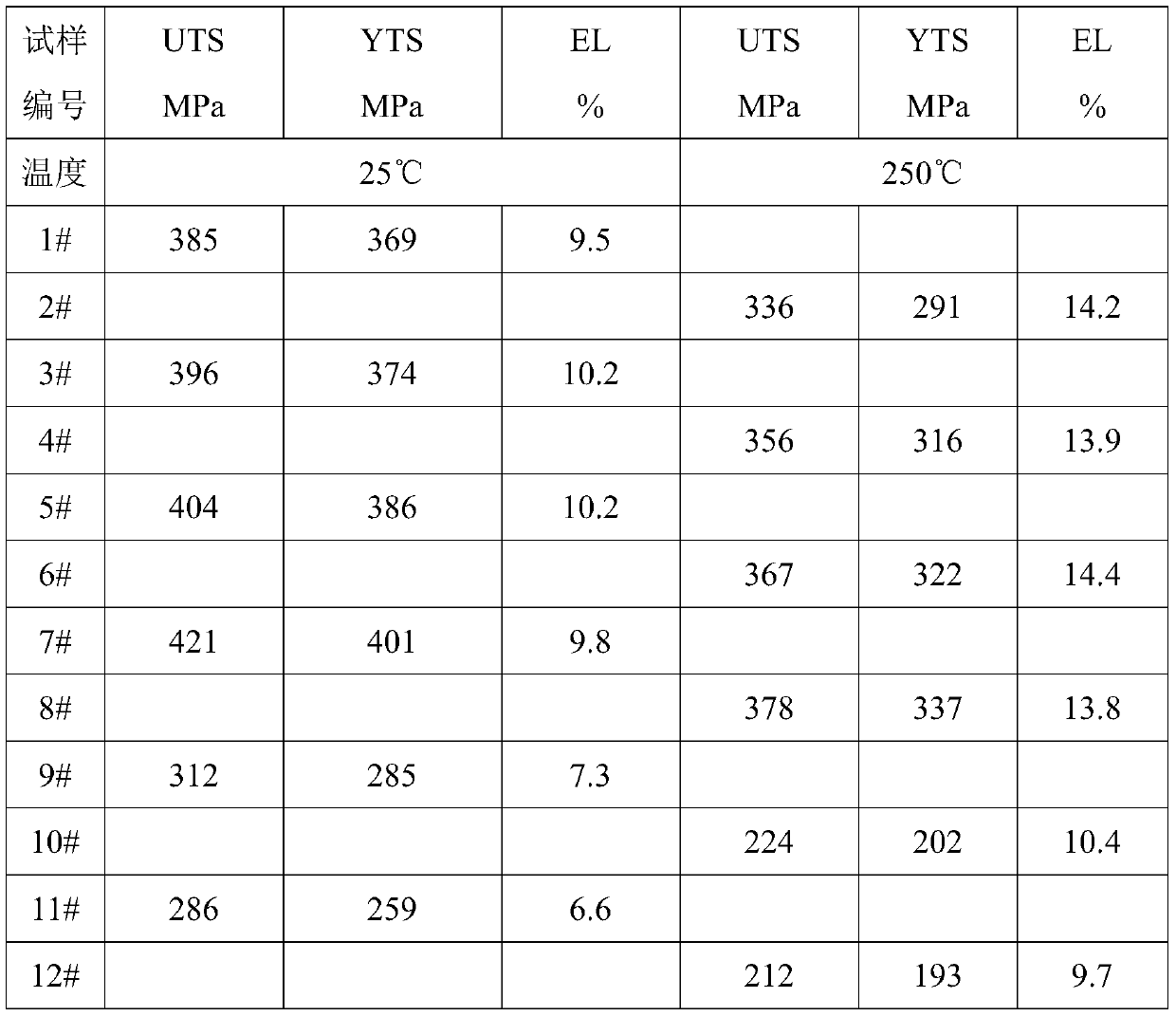

Embodiment 1

[0065] This embodiment provides a heat-resistant deformation aluminum alloy with a high melting point. According to the mass percentage, the constituent elements of the alloy include: Si.0.55%, Mg.0.85%, Mn.4.50%, Cu.0.50%, Ti.0.015 %; the balance is Al, impurity elements Zn≤0.02%, Cr≤0.001%, Zr≤0.002%, Fe≤0.15%, other unavoidable individual impurity elements content≤0.05%.

[0066] The preparation method of the high melting point heat-resistant deformation aluminum alloy provided in this embodiment comprises the following steps:

[0067] (1) After melting the aluminum ingot with a purity of 99.7% at 730°C, add crystalline silicon with a purity of 99.9%, magnesium ingot with a purity of 99.8%, and electrolytic copper with a purity of 99.9%, and electromagnetically stir the aluminum alloy solution for 20 minutes, and then pour it into the Inject anhydrous manganese chloride with a purity of 99% in the aluminum alloy liquid for 5 minutes, and react for 5 minutes under stirring. ...

Embodiment 2

[0073]The embodiment provides a high melting point heat-resistant deformation aluminum alloy. According to the mass percentage, the constituent elements of the alloy include: Si 0.60%, Mg 0.95%, Mn 5.50%, Cu 0.60%, Ti 0.018%; the balance is Al , impurity elements Zn≤0.02%, Cr≤0.005%, Zr≤0.005%, Fe≤0.15%, other unavoidable individual content of impurity elements≤0.05%.

[0074] The preparation method of the high melting point heat-resistant deformation aluminum alloy provided in this embodiment comprises the following steps:

[0075] (1) After melting the aluminum ingot with a purity of 99.7% at 735°C, add crystalline silicon with a purity of 99.9%, magnesium ingot with a purity of 99.8%, and electrolytic copper with a purity of 99.9%, and electromagnetically stir the aluminum alloy liquid for 20 minutes, and then pour it into the Inject anhydrous manganese chloride with a purity of 99% in the aluminum alloy liquid for 10 minutes, and react for 10 minutes under stirring. After ...

Embodiment 3

[0081] The embodiment provides a high melting point heat-resistant deformation aluminum alloy. According to the mass percentage, the constituent elements of the alloy include: Si 0.65%, Mg 1.00%, Mn 6.50%, Cu 0.65%, Ti 0.020%; the balance is Al , impurity elements Zn≤0.02%, Cr≤0.005%, Zr≤0.005%, Fe≤0.15%, other unavoidable individual content of impurity elements≤0.05%.

[0082] The preparation method of the high melting point heat-resistant deformation aluminum alloy provided in this embodiment comprises the following steps:

[0083] (1) After melting an aluminum ingot with a purity of 99.7% at 740°C, add crystalline silicon with a purity of 99.9%, magnesium ingots with a purity of 99.8%, and electrolytic copper with a purity of 99.9%, and electromagnetically stir the aluminum alloy liquid for 20 minutes, and then pour it into the Inject anhydrous manganese chloride with a purity of 99% in the aluminum alloy liquid for 8 minutes, and react with stirring for 8 minutes. After th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com