Automatic bag-feeding filling sealer

A sealing machine, fully automatic technology, applied in packaging sealing/fastening, external support, transportation packaging, etc., can solve the problems of unsatisfactory filling accuracy, low degree of automation, poor sealing effect, etc., and achieve a bright appearance Clean and tidy, high filling accuracy and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

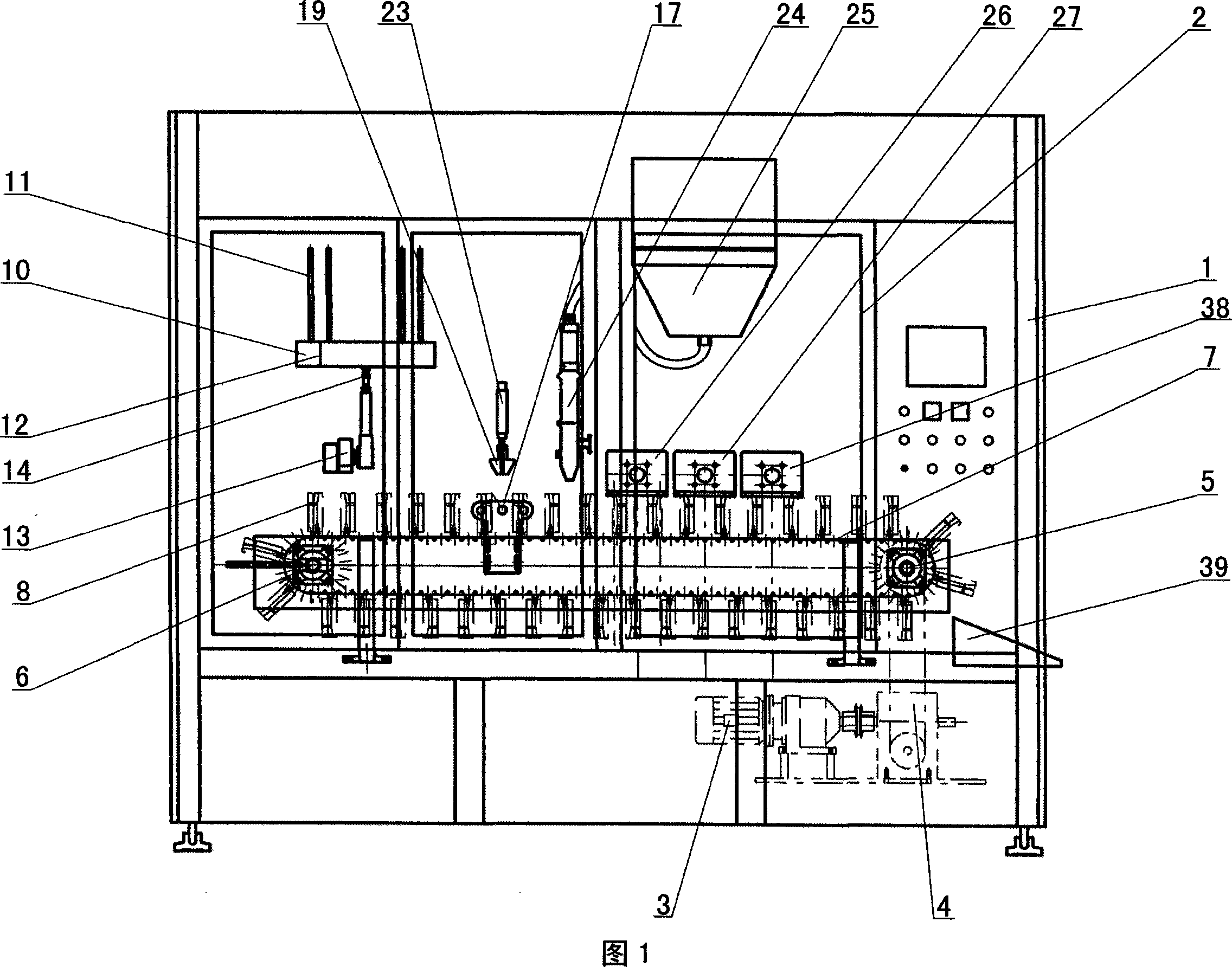

[0027] As shown in Figure 1, the fully automatic bag filling and sealing machine in this preferred embodiment includes a frame 1, a conveying device, a bag feeding device, a bag expanding device, a filling device, a heat sealing device and a cooling and shaping device, and the conveying device Installed on the frame 1, the bag feeding device, bag expanding device, filling device, heat sealing device and cooling and shaping device are sequentially arranged on the frame 1 and located above the conveying device. Above-mentioned frame 1 adopts stainless steel to make, and glass door 2 is installed on frame 1.

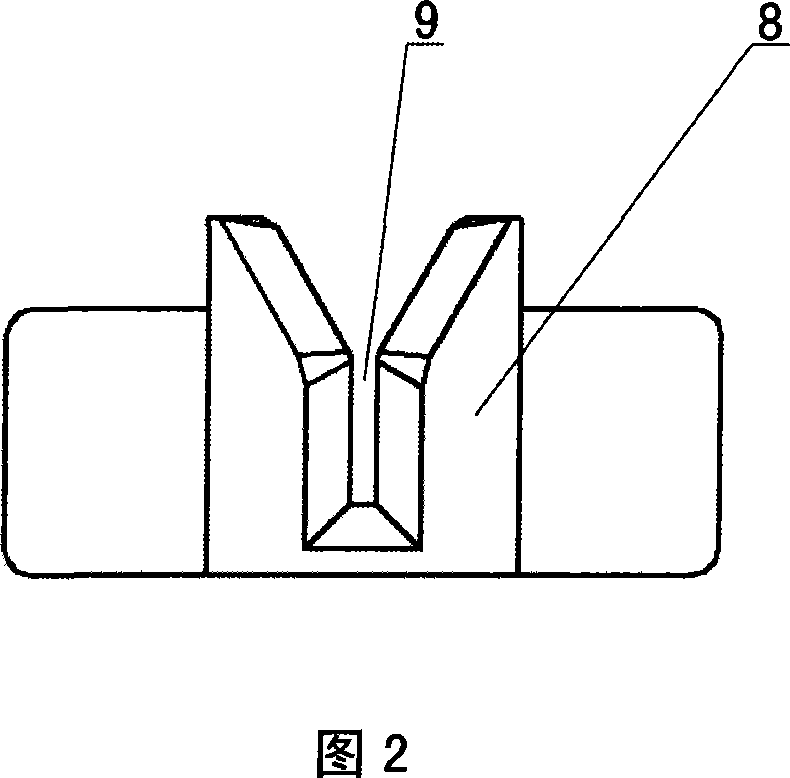

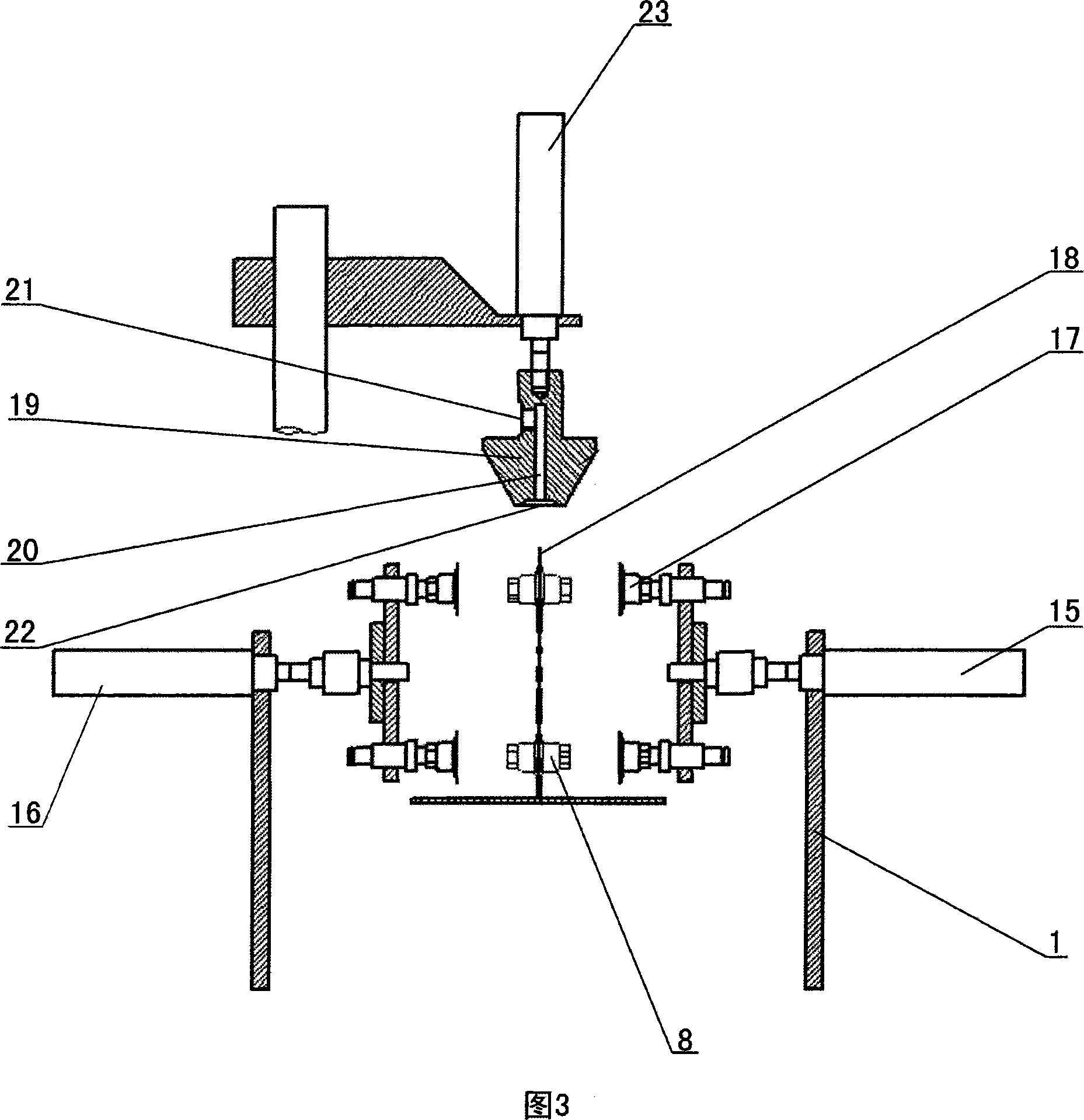

[0028] The above-mentioned conveying device comprises a power mechanism and a conveying mechanism, and the power mechanism comprises a geared motor 3 and a stepper 4, and the geared motor 3 is connected with a transmission of the stepper 4; the conveying mechanism comprises a driving sprocket 5, a driven sprocket 6, and a conveyor belt 7 And hanging bag fork 8, driving spro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com