Process for preparing light-weight calcium carbonate by recycling white mud by alkali

A technology of light calcium carbonate and white mud, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problem of non-standard whiteness and purity of light calcium carbonate, low whiteness of light calcium carbonate, incomplete purification of white mud, etc. problems, to achieve the effect of expanding product application range, improving whiteness, and improving causticizing rate of green liquor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

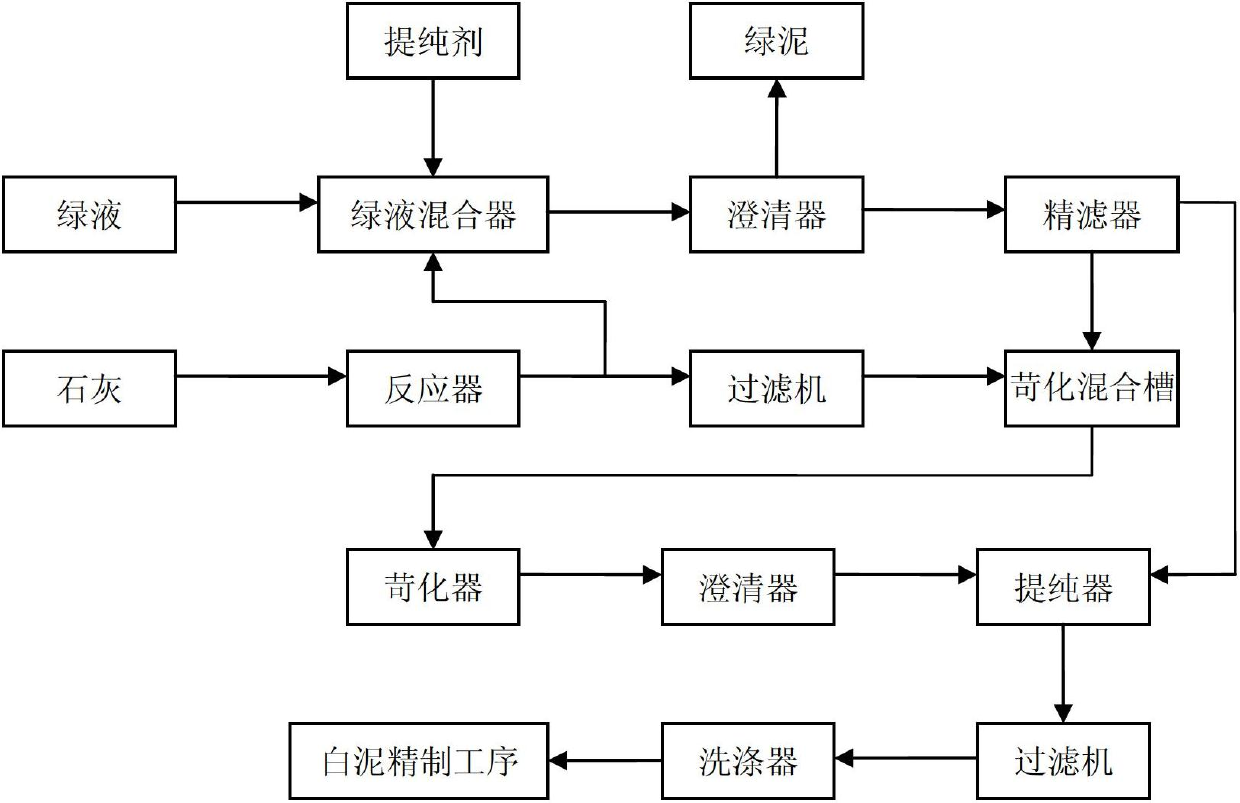

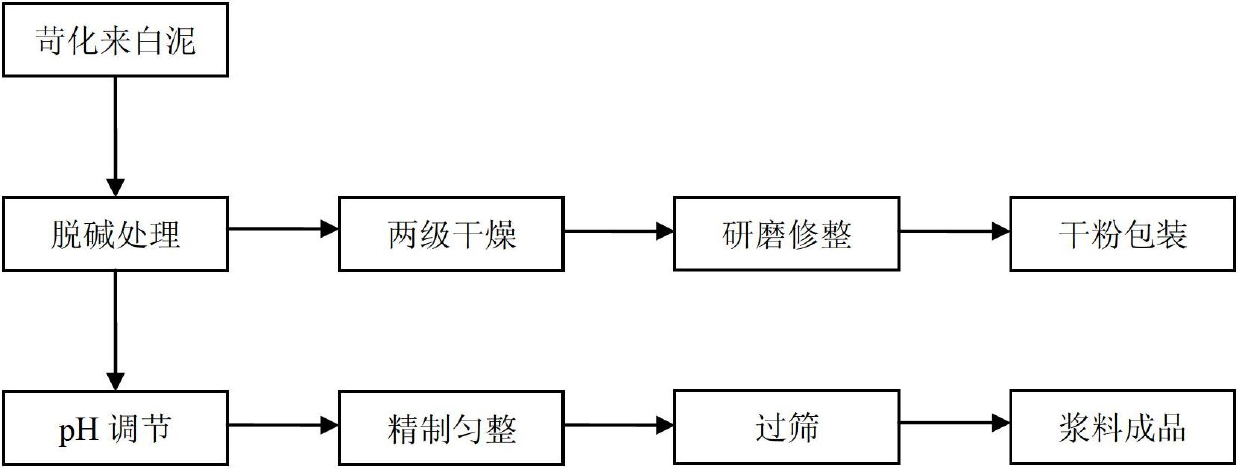

Method used

Image

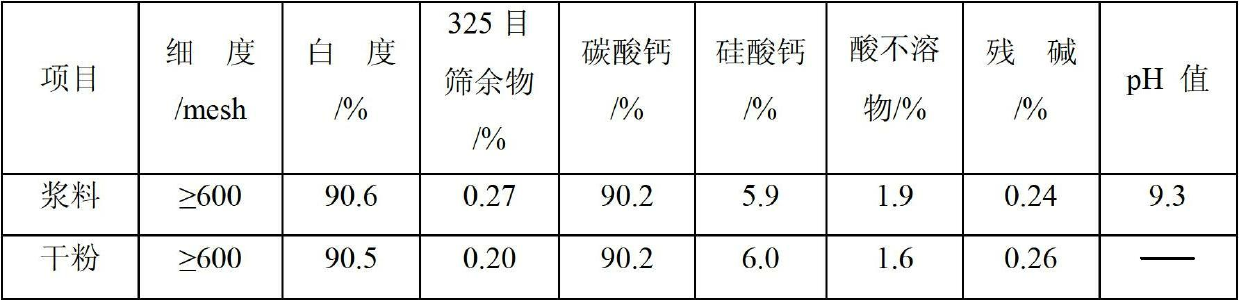

Examples

Embodiment 1

[0033] Take 8.7kg of quicklime with a calcium oxide content of 70%, add water and purifying agent EDTA, the amount of purifying agent added is 1 times the mass of iron in the lime, and the large particles of impurities in the milk of lime are removed by a digestion and slag extractor to obtain milk of lime with a mass concentration of 10% , and then through graded treatment, 5% of the total mass of lime milk (containing more impurities) is removed from the green liquor mixer to purify the green liquor, and the other part is separated from solid and liquid to prepare purified slaked lime.

[0034] Take 100L of green liquor with a sodium carbonate content of 110g / L and mix it with the milk of lime in the above-mentioned degreen liquor mixer, then add the purifying agent ATMP, the amount of purifying agent added is 3 times the mass of impurities in the green liquor, the reaction temperature is 60°C, keep stirring After 20 minutes, let it stand for clarification, and then fine filt...

Embodiment 2

[0043] Take 8.1kg of quicklime with a calcium oxide content of 75%, add water and purifying agent DTPA, the amount of purifying agent added is 5 times the mass of iron in the lime, and make milk of lime with a mass concentration of 20%. The large particles of impurities in the milk of lime are first removed, and then classified For treatment, 20% of the total mass of milk of lime (containing more impurities) is removed from the green liquor mixer to purify the green liquor, and the other part is separated from solid and liquid to prepare purified slaked lime.

[0044] Mix 100L of green liquor with a sodium carbonate content of 110g / L with the milk of lime in the above-mentioned degreen liquor mixer, then add the purifying agent EDTMP, the amount of purifying agent added is 6 times the mass of impurities in the green liquor, the reaction temperature is 80°C, keep stirring for 15min Finally, let it stand for clarification, and the upper part is cleared and then finely filtered th...

Embodiment 3

[0053] Take 7.6 kg of quicklime with a calcium oxide content of 80%, add water and purifying agent HEDTA, the amount of purifying agent added is 10 times the mass of iron in the lime, and make 30% lime milk. The large particles of impurities in the lime milk are first removed, and then through classification. 40% of the total mass of lime milk (containing more impurities) is removed from the green liquor mixer to purify the green liquor, and the other part is separated from solid and liquid to prepare purified slaked lime.

[0054] Mix 100L of green liquor with a sodium carbonate content of 110g / L with the milk of lime in the above-mentioned degreen liquor mixer, then add the purifying agent DTPA, the amount of purifying agent added is 10 times the mass of impurities in the green liquor, the reaction temperature is 90°C, keep stirring for 10min Finally, let it stand for clarification, and the supernatant liquid is finely filtered through a fine filter to obtain purified green l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com