Process for preparing alumina by two-component sintering method

A preparation process and alumina technology, which are applied in the preparation of alumina/hydroxide, alkali metal aluminate/alumina/aluminum hydroxide, alumina/aluminum hydroxide, etc., can solve problems such as loss and achieve The effect of improving the grade, reducing the material flow and lowering the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

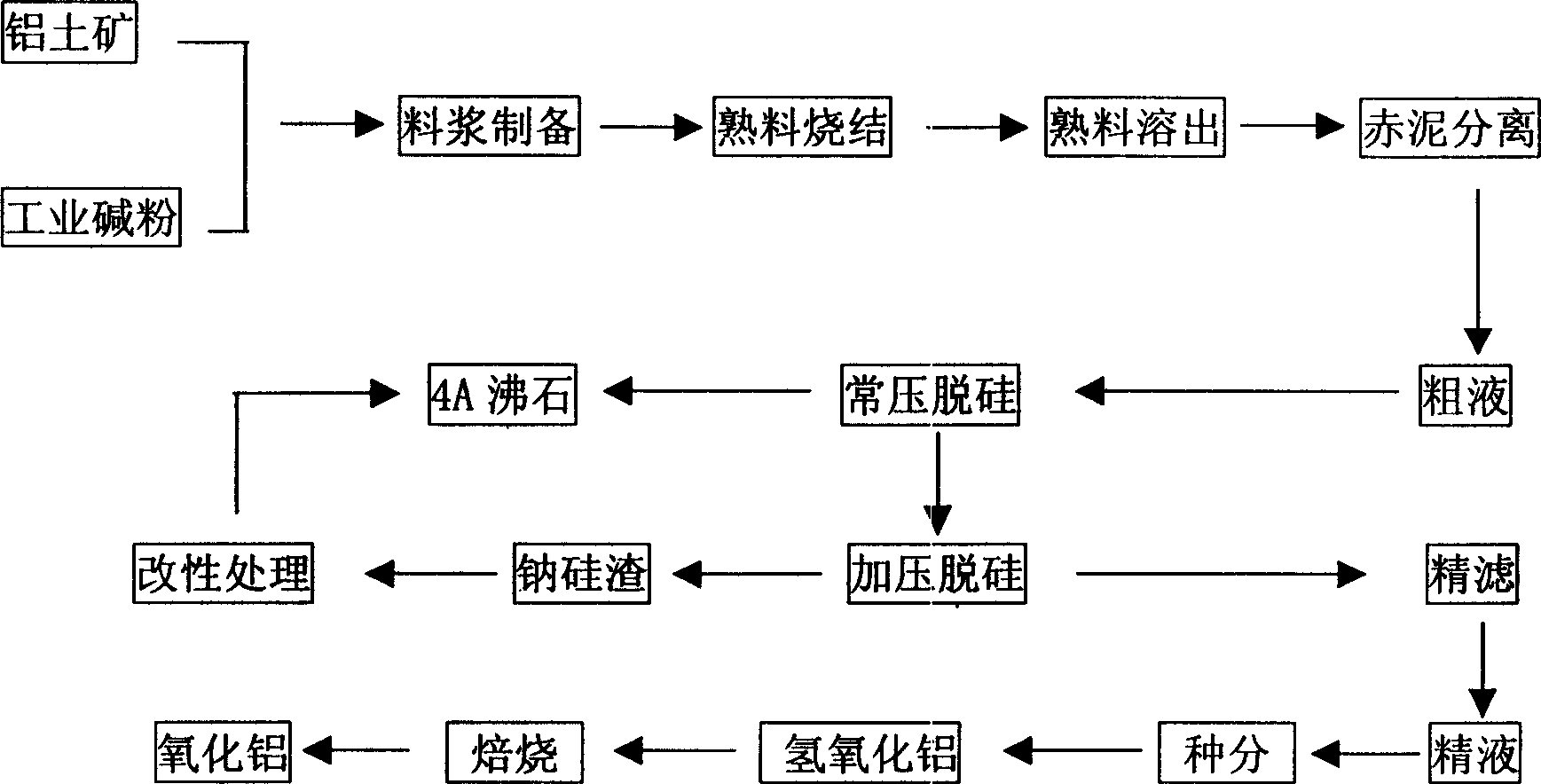

[0022] The two-component sintering alumina preparation process of the present invention is as follows:

[0023] The chemical weight percent of the bauxite used is: SiO 2 7.19, Fe 2 o 3 5.25, Al 2 o 3 67.82, CaO 8.50, Na 2 O 0.6,K 2 O 0.55, TiO 2 2.91, other 7.18, ore burning reduction 13.55%;

[0024] The main phase weight percentage of bauxite used is: diaspore 78.5, anatase 2.8, kaolinite 3.5, quartz 1.3, hematite 4.2, others 9.7;

[0025] The slurry preparation is based on the weight ratio of bauxite and industrial alkali powder of 1:0.30, adding bauxite and industrial alkali powder to the raw material mill, and adding 1.39m of high-concentration evaporated carbon mother liquor per ton of bauxite 3 , The slurry is ground to a residue of 12% on a 120 mesh sieve.

[0026] The above slurry is sent to the rotary kiln to burn the two-component clinker. The firing temperature is 1160-1180°C. The residence time of the material in the clinker kiln is 2.0 hours. The wei...

Embodiment 2

[0032] The two-component sintering alumina preparation process of the present invention is as follows:

[0033] The chemical weight percent of the bauxite used is: SiO 2 9.19, Fe 2 o 3 5.05, Al 2 o 3 65.82, CaO 8.30, Na 2 O 0.6,K 2 O 0.54, TiO 2 2.89, other 7.18, ore burning reduced by 14%;

[0034] The slurry preparation is based on the weight ratio of bauxite and industrial alkali powder of 1:0.31, adding bauxite and industrial alkali powder to the raw material mill, and adding 1.40m of high-concentration evaporated carbon mother liquor per ton of bauxite 3 , The slurry is ground to 10% on the 120 mesh sieve.

[0035] The above slurry is sent to the rotary kiln to burn the two-component clinker. The firing temperature is 1150-1160°C. The residence time of the material in the clinker kiln is 2.5 hours. The weight percentage of the obtained two-component clinker is: SiO 2 9.88, Fe 2 o 3 3.96, Al 2 o 3 43.50, CaO 3.00, Na 2 O 34.29, K 2 O 2.20, Na 2 o S ...

Embodiment 3

[0041] The two-component sintering alumina preparation process of the present invention is as follows:

[0042] The slurry preparation is based on the weight ratio of bauxite and industrial alkali powder of 1:0.29, adding bauxite and industrial alkali powder to the raw material mill, and adding 1.44m of high-concentration evaporated carbon fraction mother liquor per ton of bauxite 3 , The slurry is ground to a residue of 14% on a 120 mesh sieve.

[0043] The above slurry is sent to the rotary kiln to burn the two-component clinker, the firing temperature is 1180-1200°C, and the residence time of the material in the clinker kiln is 2 hours to obtain the two-component clinker;

[0044] The two-component clinker is dissolved in the dissolution wet mill together with the adjustment solution, and the addition amount of the adjustment solution is 4.5m 3 / t-clinker, the dissolution temperature is 77-79°C;

[0045] After the clinker of the two components is dissolved, the liquid-sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com